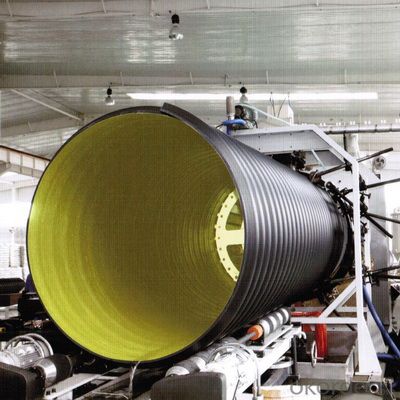

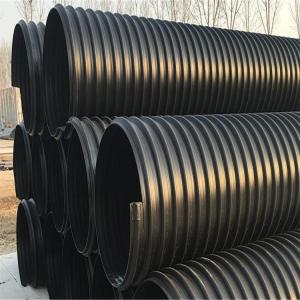

HDPE Corrugated Pipe Drainage Conduit With Steel Belt Reinforced

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features and Benefits

1. Distinguished comprehensive performances

2. Safe and reliable ring stiffness

3.Light weight

4.Simple installation, good sealing and low cost of construction

5.Producing on the construction site, saving the transportation charges and construction costs heavily

6.Strong load capacity to resist improper burst

Other Features Same with PE Pipes:

1.Anticorrosion

2.Anti- ultraviolet

3.Smooth internal surface

4.Impact resistance

5.Toughness

6.Nonpoisonous

7. Abrasion resistance

8. Long operating life, as long as 50 years

Application Areas

1. Public works: used as drainage pipe and blow-off pipe while buried under the ground.

2.Road works: used as soakaway trench or drainage pipe in railways and express ways.

3.Industry: widely used as sewage pipe in industry area.

4.Construction works: used as rain pipe of buildings, underground drainage pipe, blow-off pipe, vent pipe, etc.

5. Dirty water collecting pipe in refuse landfills.

6.Large-scale port and wharf projects: used as drainage pipe and blow-off pipe in projects of large-scale airport, port and wharf.

7.Sport stadium: used as soakaway trench and drainage pipe in sport stadium, such as golf course and football field.

8.Water conservancy project: used as water-head pipe and irrigation pipe.

9.Mine field: used as vent, blast, drain and slurry pipe.

10.Communication engineering: used as railway and highway communication pipe, communication cable pipe and optical cable protective pipe.

11.Water storage system: used in the water storage system to trap slow-flowing stream.

12.Agricultural engineering: used as irrigation pipe on the farm, in the garden,the tea garden and the forest belt.

13.Seawater transporting pipe

14.Clear the river channel

Diameter Nominal DN/ID,mm | Internal Diameter DN/ID,mm | Ring Stiffness Rank | ||

SN8 | SN10 | SN12.5 | ||

≥8KN/m2 | ≥10KN/m2 | ≥12.5KN/m2 | ||

External Diameter de,mm | External Diameter de,mm | External Diameter de,mm | ||

200 | 200 | 224 | 224 | |

300 | 300 | 325 | 325 | |

400 | 400 | 438 | 438 | |

500 | 500 | 539 | 539 | |

600 | 600 | 644 | 644 | 644 |

700 | 700 | 745 | 745 | 745 |

800 | 800 | 852 | 852 | 852 |

900 | 900 | 963 | 963 | 963 |

1000 | 1000 | 1063 | 1063 | 1063 |

1100 | 1100 | 1173 | 1173 | 1173 |

1200 | 1200 | 1273 | 1273 | 1273 |

1300 | 1300 | 1385 | 1385 | 1385 |

1400 | 1400 | 1485 | 1485 | 1485 |

1500 | 1500 | 1585 | 1585 | 1585 |

1600 | 1600 | 1693 | 1693 | 1693 |

1700 | 1700 | 1793 | 1793 | 1793 |

1800 | 1800 | 1893 | 1893 | 1903 |

2000 | 2000 | 2105 | 2105 | 2121 |

2200 | 2200 | 2307 | 2307 | 2323 |

2400 | 2400 | 2527 | 2527 | 2533 |

2500 | 2500 | 2629 | 2629 | 2635 |

2600 | 2600 | 2729 | 2729 | 2743 |

2700 | 2700 | 2848 | 2848 | 2858 |

2800 | 2800 | 2958 | 2958 | 2973 |

- Q: Can plastic tubes be used for storing pharmaceuticals?

- Yes, plastic tubes can be used for storing pharmaceuticals.

- Q: How do you prevent plastic tubes from melting in high temperatures?

- One effective way to prevent plastic tubes from melting in high temperatures is by using heat-resistant materials such as high-density polyethylene (HDPE) or polytetrafluoroethylene (PTFE) for tube manufacturing. These materials have high melting points and can withstand elevated temperatures without deformation or melting. Additionally, proper insulation and cooling systems can be implemented to minimize heat transfer and maintain a safe operating temperature for the plastic tubes.

- Q: GFs birthday coming up and I want to give her something special... any suggestions as to what I can make?

- some dough to get a real gift. ^_^

- Q: What is the level of transparency of plastic tubes?

- The level of transparency of plastic tubes varies depending on the type and quality of the plastic used. Some plastic tubes can be completely transparent, allowing for a clear view of the contents inside, while others may have a certain degree of opacity, making it difficult to see through. It is important to consider the specific requirements and intended use of the plastic tubes when determining the desired level of transparency.

- Q: Im looking for some hard plastic tubes like pvc, but clear about 3 ft in length. Any stores that might have something like that?

- Meijers might have this.

- Q: I am making a functional balloon water pipe. if at all possible a valve with an electric switch would be ideal so it could be activated from inside a balloon. the tubing will be inside the balloons so they can be pressurized around the tubes. after the tubing is filled with smoke it will be sealed off and the pressure from a balloon will be released forcing the smoke through the tubing inside the pipe. this is what the valve would be used for. a simple ball valve would work, but if there is an electric version small and cheap enough or an alternative im open to suggestions.

- Gag, what a dumb concept - balloons break. All kinds of small valves are available for plastic tubing for use in medicine but turning on and off the pump is probably the cheapest. You need surgical rubber tubing to be soft and compressible which is probably going to be damaged by the smoke and how are you going to clean this thing?

- Q: I have the heads for the cake decors, but I dont have the tube I think thats what you call it. Could I just use a plastic sandwich bag and tie it on with rubber bands. Will this work? or will it just make a mess? Thank you.

- I have tried to do this several times. I am always hopeful that it will work. Sometimes it does and sometimes it doesn't. In general, your icing can't be too thick, and your pressure on the bag can't be too heavy, or the bag breaks and you end up with a gloppy mess. It is also important to note that the cheaper the quality of the bag, the more likely you are to break it. If you take your time, and practice on a piece of wax paper (or similar) prior to starting on the cake, I think you will be able to do it. Especially if you have experience decorating cakes! Best of luck!

- Q: What are the advantages of using plastic tubes in plumbing applications?

- There are several advantages of using plastic tubes in plumbing applications. Firstly, plastic tubes are lightweight and easy to handle, making them convenient for installation and transportation. Additionally, they are resistant to corrosion, which ensures a longer lifespan compared to traditional metal pipes. Plastic tubes also have a smooth interior surface, reducing the risk of clogs and improving water flow. Furthermore, they are cost-effective, as plastic materials are generally cheaper than metal alternatives. Lastly, plastic tubes are highly versatile, as they can be easily molded into various shapes and sizes to fit specific plumbing needs.

- Q: Can plastic tubes be used for wire insulation?

- Yes, plastic tubes can be used for wire insulation.

- Q: What is the PVC composite pipe and what is the difference between it and the plastic pipe?

- Plastic pipes are usually made of synthetic resins, that is, polyester as raw materials, adding stabilizers, lubricants, plasticizers, etc., to "plastic" method in the pipe mill by extrusion processing. Because of its light weight, corrosion resistance, beautiful appearance, no bad smell, easy processing, convenient construction and other characteristics, it has been more and more widely used in building engineering. Mainly used for building construction of the water supply system, piping, drainage, exhaust and sewage sanitary pipe, underground drainage pipe system, storm pipe and wire installation supporting the use of threading pipe.

Send your message to us

HDPE Corrugated Pipe Drainage Conduit With Steel Belt Reinforced

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords