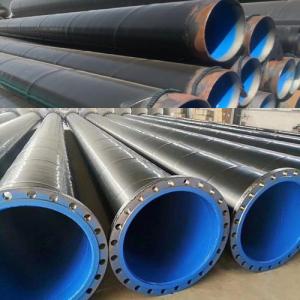

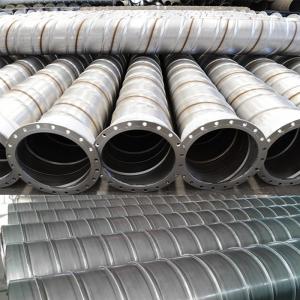

Spiral Welded Plastic-coated Epoxy Resin Steel Pipe with Reinforcement Bar for Coal Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Spiral Welded Plastic-coated Epoxy Resin Steel Pipe with Reinforcement Bar for Coal Mining

Press grade: Maximum PN -0.097MPa

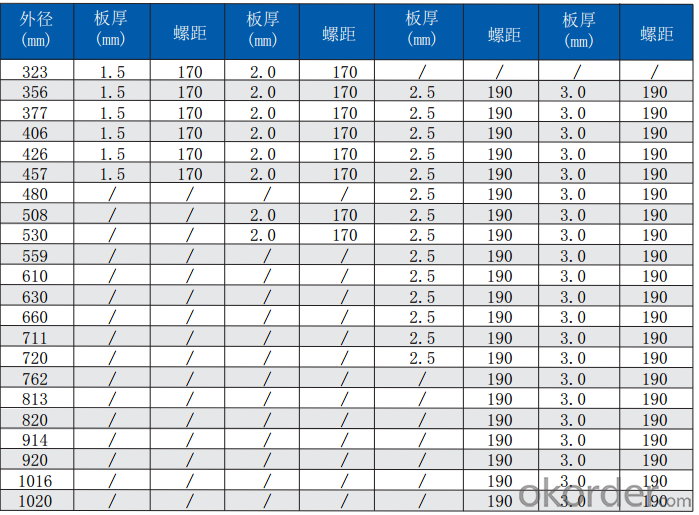

Size: DN300MM-DN1000MM

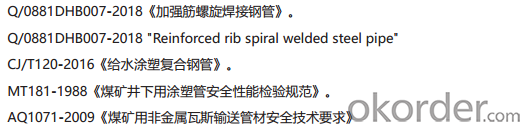

Standards:

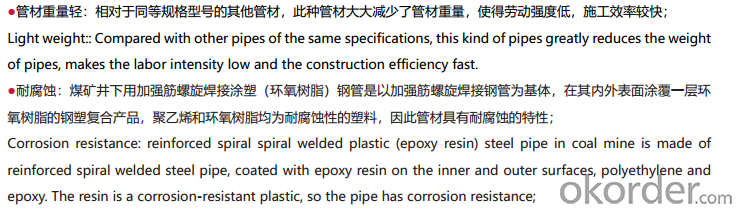

Features:

Specification:

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: Fastener type steel pipe scaffold external parts name

- Even the wall piece the upright rod is connected with the main structure together, available steel tube, fastener or embedded part. Rigid wall, also can be used as a flexible reinforced wall connecting piece of the tie bar. , 5.The base in the form of plug-in and coat type two, inserted a D1 diameter rod diameter than 2mm, diameter D2 rod diameter than 2mm type jacket.

- Q: What are the different sizes of threads available for steel pipes?

- The different sizes of threads available for steel pipes vary depending on the specific requirements and standards. Common thread sizes for steel pipes include 1/8", 1/4", 3/8", 1/2", 3/4", 1", 1-1/4", 1-1/2", 2", 2-1/2", 3", 3-1/2", 4", 5", 6", 8", 10", and 12". However, these sizes may vary based on the specific industry, country, and application.

- Q: What are the challenges faced in transporting steel pipes?

- There are several challenges faced in transporting steel pipes. Firstly, their sheer weight and size make it difficult to handle and transport them. Specialized equipment and vehicles are required to lift and transport these heavy pipes safely. Secondly, steel pipes are susceptible to damage during transportation. They can get scratched, dented, or bent, which can compromise their structural integrity. Proper packaging and securement are crucial to prevent any damage during transit. Additionally, due to their length, steel pipes may exceed the legal limits for road transportation, requiring special permits and escorts. Lastly, ensuring timely delivery and coordination between multiple parties involved in the transportation process can be a logistical challenge.

- Q: What are the limitations of using steel pipes?

- Using steel pipes in various applications has several limitations. Firstly, the cost of steel pipes compared to materials like plastic or copper can be quite high. This can be a significant drawback for projects with limited budgets. Secondly, steel pipes are susceptible to corrosion. Exposure to moisture and certain chemicals over time can cause rust and deterioration. This can lead to leaks, reduced structural integrity, and the need for expensive repairs or replacement. Another limitation is the weight and rigidity of steel pipes. They are generally heavier and less flexible than other types of pipes, making installation and maneuvering more challenging in certain settings. Additionally, their rigid nature makes them less suitable for applications requiring movement or flexibility. Furthermore, steel pipes can experience thermal expansion and contraction. Extreme temperatures can cause them to expand or contract, potentially stressing joints, fittings, or other components. This can lead to leaks or even pipe failure if not properly addressed. Lastly, steel pipes are not as resistant to certain chemicals or substances as other materials. Some chemicals can corrode or erode the inner lining, compromising integrity and potentially causing contamination or leakage. While steel pipes have advantages, it is important to consider these limitations when selecting the most suitable material for a specific application.

- Q: Can steel pipes be used for underground water supply pipelines?

- Yes, steel pipes can be used for underground water supply pipelines. Steel pipes are strong, durable, and resistant to corrosion, making them suitable for underground applications. They are often used for water supply pipelines due to their high strength and ability to withstand high pressure and load. Additionally, steel pipes can be welded together, ensuring leak-free connections, and are available in various sizes to accommodate different water supply needs.

- Q: What is the hardness of steel pipes?

- The specific grade and manufacturing process can cause the hardness of steel pipes to vary. Generally, alloys are used to make steel pipes, which offer a combination of strength and toughness. To determine the hardness of steel pipes, different methods like Rockwell or Brinell hardness tests can be carried out. These tests gauge the steel's resistance to indentation or penetration using a standardized indenter. The hardness of steel pipes is usually represented as a numerical value on a scale, like the Rockwell hardness scale (e.g., HRC or HRB) or the Brinell hardness scale (e.g., HB). The hardness of steel pipes is significant as it indicates their capacity to endure physical stresses, such as pressure, impact, or wear, in various applications such as construction, oil and gas transportation, and manufacturing.

- Q: How are steel pipes classified according to their use?

- Steel pipes can be classified according to their use into various categories such as structural pipes, plumbing pipes, oil and gas pipes, water supply pipes, and industrial pipes.

- Q: Where is the difference between seamless steel pipe and welded pipe?

- Seamless steel tube is formed during rolling. Welded steel pipes need to be welded after coiling, and spiral welding and direct welding are generally used. Seamless performance is better, of course, the price is higher.

- Q: Can steel pipes be used for paper mills?

- Yes, steel pipes can be used for paper mills. Steel pipes are often used in paper mills for various applications such as transporting water, steam, chemicals, and pulp. They are preferred for their durability, resistance to corrosion, and ability to handle high pressure and temperature conditions commonly found in paper mill operations.

- Q: How are steel pipes used in the mining industry?

- Steel pipes are commonly used in the mining industry for various purposes such as transporting minerals, water, and gases underground, as well as for constructing mine shafts, tunnels, and mine infrastructure due to their durability, strength, and resistance to corrosion.

Send your message to us

Spiral Welded Plastic-coated Epoxy Resin Steel Pipe with Reinforcement Bar for Coal Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords