Wholesale HDPE Tri-Dimension Compound Geonet / Plastic Drainage Matting Roll

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

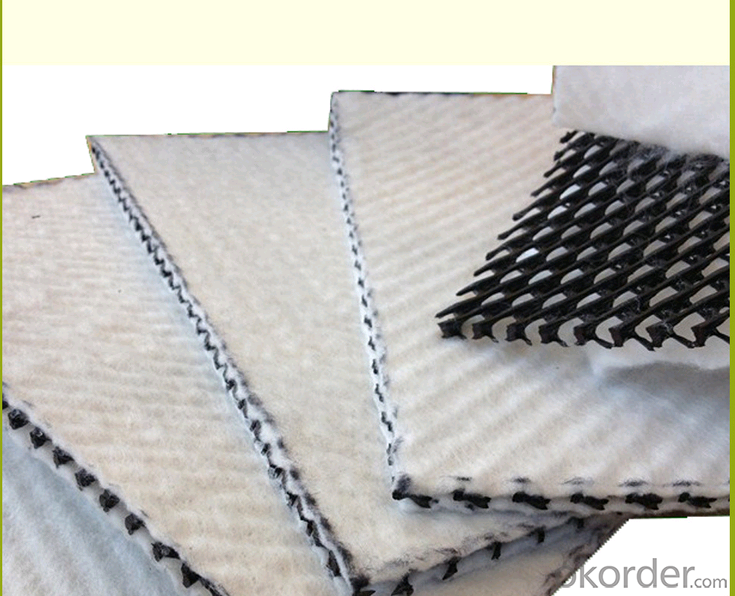

Tri -dimension composite geonet / geonets and geocomposites

Be made of tri-dimension geonet coated geotextile on both sides, has the property of geotextile (filtration) and geonet (drainage and protection), and has the complete function of "filtration--drainage-- protection"

Application

landfill drainage

hignway roadbed

railaway drainage

tunnel drainage

underground structure drainge

retaining walls drainage

garden and playground drainage

Feature

- stronger drainage function and can bear high press load for a long time

- high tensile strength and shear strength

- keep stable water conductivity

- can bear compression load of more than 2000kpa

- larger anti-compression capacity than common geonet

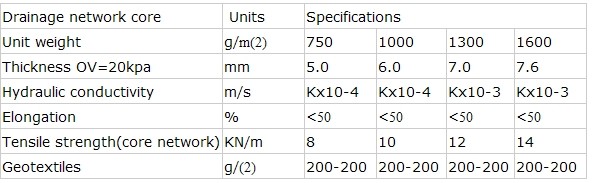

Tri-dimension composite geonet technical specifications

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: How many models of composite geo-membrane are there?

- Composite geo-membrane models are 0.1-1.5mm, 0.2-1.5mm, 0.1-0.8mm, 0.1-0.8mm. Composite geomembrane is water impermeable material composited by geotextile and geomembrane for seepage prevention. Its physical and mechanical properties such as tensile, tear, bursting resistance are high, so that it can meet the needs of water?conservancy, municipal engineering, construction, transportation, subways, tunnels and so on. Because it uses high polymer material and adds antioxidant during production process, it can be used in unconventional temperature environment.

- Q: Can geomembranes be used in secondary containment systems?

- Yes, geomembranes can be used in secondary containment systems. Geomembranes are impermeable liners made from synthetic materials that prevent the leakage of liquids or gases. They can be installed as liners or covers in secondary containment systems to provide an additional layer of protection against spills or leaks that may occur in primary containment systems. Geomembranes are commonly used in industries such as oil and gas, chemical storage, and waste management to ensure environmental safety and compliance with regulations.

- Q: Does the mobile phone stick the tempered film or ordinary film?

- The tempered film is very good, mainly because it is more durable, which can protect the mobile phone screen, and the quality of the tempered film is very good. Ordinary film is easy to break the phone screen, the protective effect is weak, but also it should be replaced frequently.

- Q: Is far infrared ray electrothermal film good?

- If it is great, then we can not be exposed to the sun. The far infrared ray is part of the solar ray, and is the most important light to living things, thus it is known as "the ray of life". Among all the sun's rays, infrared rays are most likely to penetrate into skin and subcutaneous tissue. Due to the proximity of vibration frequency between the far infrared ray and the cell as well as molecular of human body, the far infrared will cause resonance of atoms and molecules of human cells when it penetrates the body. Through the resonance absorption, moleculars will rub with each other causing the thermal reaction, prompting the deep temperature of skin to rise and accelaraing expansion of microvascular and the blood circulation, which is conducive to removing blood accumulation, the body of harmful substances and barriers to the metabolic disorder, reviving tissues, promoting the generation of enzyme, activating cells, preventing aging and strengthening the immune system. So far infrared ray is able to improve and prevent diseases caused by blood circulation and microcirculation disorder.

- Q: Can geomembranes be used for wastewater lagoons?

- Yes, geomembranes can be used for wastewater lagoons. Geomembranes are often used as liners in wastewater lagoons to prevent leakage and contamination of surrounding soil and groundwater. They provide an impermeable barrier that helps to contain and manage wastewater effectively.

- Q: What is the expected lifespan of a geomembrane in a wastewater treatment plant?

- The expected lifespan of a geomembrane in a wastewater treatment plant can vary depending on various factors such as the quality of the material, installation techniques, and maintenance practices. On average, a well-designed and properly maintained geomembrane can last anywhere from 20 to 30 years. However, with advancements in technology and the use of high-quality materials, some geomembranes have been known to last even longer, exceeding 30 years.

- Q: Can geomembranes be used in tunnel construction?

- Yes, geomembranes can be used in tunnel construction. They are often used as a protective layer to prevent water infiltration and provide waterproofing for tunnels. Geomembranes act as a barrier between the tunnel structure and surrounding soil or groundwater, ensuring the structural integrity and longevity of the tunnel.

- Q: What is the welding method of geotextile?

- It is easy to weld the geotextiles that manual rolling and paving is enough. The surface should be flat with some deformation allowance left. The long or short nonwoven geotextiles are often bonded by lapping, seaming and welding. The seamed and welded overlap is generally more than 0.1m wide. The lapped overlap is generally more than 0.2m wide. For geotextiles with long exposure time, methods of welding and seaming are recommended. Continue seaming until the all the work is completed. (disconnected seaming is not allowed.) Before being bonded, the overlaps should not be less than 150mm wide. The minimum distance of seams to the edges (the exposed edge of material) is 25mm. The thread for seaming should be made from resin with tensile strength no less than 60N, with chemical resistance and UV resistance that are the same with that of geotextile or exceed that of geotextile. Any "missed stitch" should be avoid. Actions should be taken accordingly to prevent emission of soil, particulate matters or foreign matters.

- Q: What are the construction steps of seepage-proof geomembrane?

- Pave along a certain direction smoothly with proper tension to adapt a small amount of subsidence. 2. set aside 10 cm along the edges of geomembrane, use professional heat-welding welder during welding, and use sack closers to stitch geotextile. 3.as for paved geomembranes edge, oil stains, water, dust and so on can not be found in seams of geomembranes so as not to affect the quality of welding. 4. PE single films on both sides of seams must be adjust well before welding, then reserve a certain with before lapping, and the lapping width is generally 6 to 8 cm which needs to be smooth and wrinkle-free. 5. construction procedures: weld PE film stitch the understratum cloth turn over the cloth and stitch the upper cloth

Send your message to us

Wholesale HDPE Tri-Dimension Compound Geonet / Plastic Drainage Matting Roll

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords