Tower Crane TC6016 10 Ton Max Lifting Capacity

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

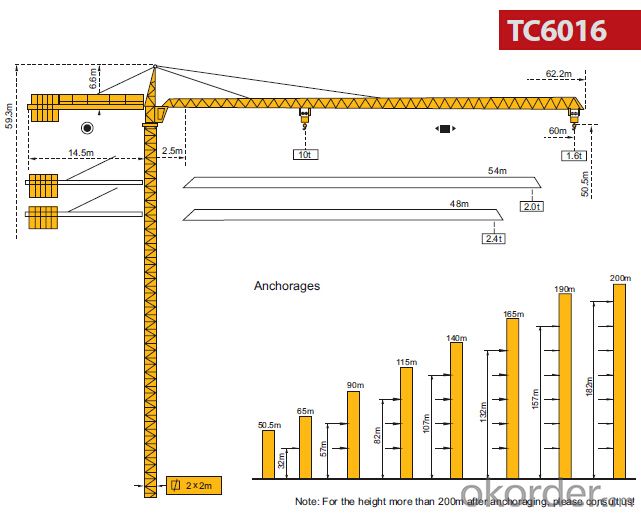

Detail of Tower Crane

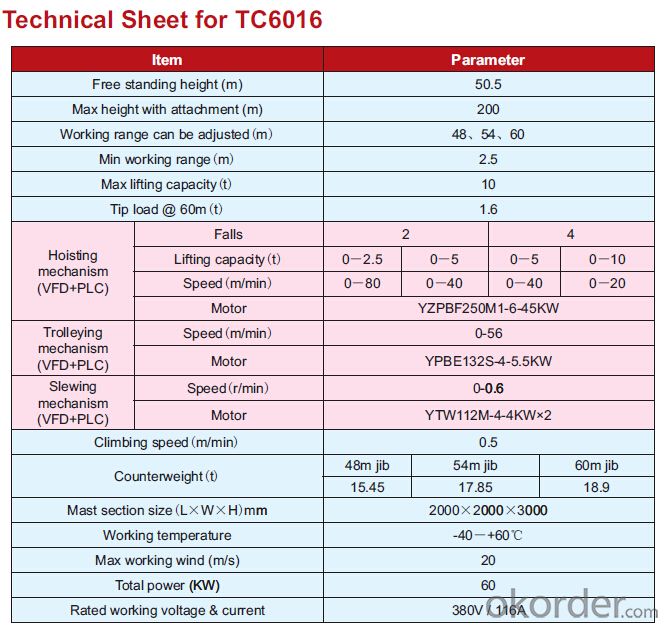

Feature:Tower Crane Condition:New Model Number:TC6016(QTZ100) Place of Origin: China (Mainland) Brand Name: CMAX Certification: ISO,CE Warranty: 1 Year Application:Building,Construction,Industrial

Main Features of Tower Crane

1) This series of tower cranes, ranging from QTZ40 to QTZ400 has a horizontal jib frame, a jib-trolley radius-changing mechanism and a hydraulic self-raising mechanism. It is original in design, reliable in operation and satisfactory in shape. Equipped with all necessary safety devices, these cranes show a good speed-control capacity, satisfactory operating stability and high work efficiency. They can be widely used for the construction of high-rise hotels, residential buildings, high-rise industrial buildings, large-span factory buildings and tower-like buildings like tall chimneys.

2) It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed. 3)The range-change structure drives the trolley moving on the horizontal crang jib, with good positioning performance. Planet gear decelerator is applied in the circumgyrating structure, together with moment-limiting hydraulic coupler, which can relize high load capacity, steady starting and reliable operation.

4) The crane has complete set of safety devices, which can guarantee the safe and high efficienct operation. The crane is equipped with lifting height limiter, trolley ranging limiter, moment limiter, weight limiter etc..

5)The cranehas scientific layout and handsome appearance. The drivers cab is set independently on one side, with good vision field. It creates a good working environment for the operator.

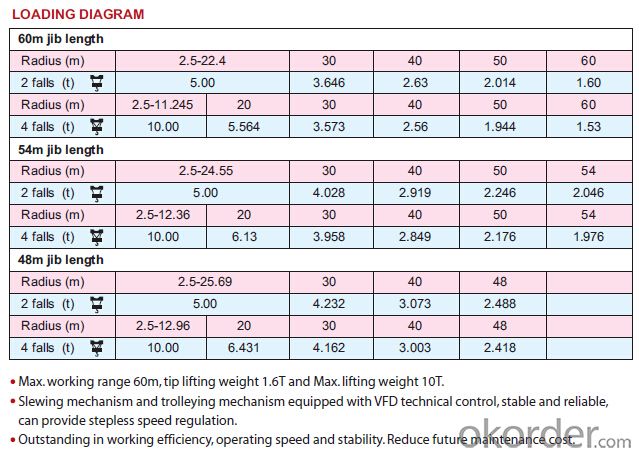

Specification of Tower Crane

Images of Tower Crane

FAQ about Tower Crane

Q: What serice you could provide? A: Providing timely delivery, standby engineers are ready to slove any of your problem Providing all-embraced warranty of products quality, worksite installation guidance Providing ample spare parts and training of operation and maintenance Engineers have more than 20 years' experience in tower crane, ready to solve any of your problems.

Q: What kind of steel used for tower crane ? A: Normally, as for the main force bearing steel structure, Q345B is adopted; as for the assistance force bearing steel structure Q235B is adopted. All of the raw material is outsourced from qualified steel factory in China.

Q: What about our tower crane warranty? A: Usually there is one-year quality warranty including main electronic parts (not including consumable parts). There are consumable spare parts together with whole machine and normally they are enough for one year.

Q: What is 3 main mechanism of the tower crane ? A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer? A: Sure. All of these could be provided with extra cost upon the clients' requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view. | |||||

| (0) | |||||

- Q: are parts availble for shop crane? Hydraulic ram plunger o rings has split....need part?

- You okorder / and buy a whole new jack. I replace one with Northern about two years ago. I got one that pumps on the up, and down stroke. Works better than the original!

- Q: I was told that this was taking place, so i would like to fax the info to the proper local

- Is it a seeing eye dog?

- Q: I've heard that if one were to make 1000 paper cranes, then they would get one wish. Is this true?I've been making paper cranes for a few days now.

- this is like asking: in case you're making a wish on a capturing megastar, will it come genuine? besides the actuality that the two are effective gestures, no it won't come genuine. Origami cranes are purely products of paper that are folded to resemble birds; no count number what proportion you're making, they gained't handle supernatural understand-how including wish-granting.

- Q: For those of you who know about the tradition where you make origami cranes and can make a wish, is it 999 cranes or 1,000 cranes? Cuz I just finished making 999, but I'm not sure if it's actually supposed to be a thousand instead.

- It is susposed to be 1000 cranes. You string them in 10 sets of 10 cranes. [thats how I remember!]Can you send me your way of folding them? I can't find one that works right for me, they always turn out a little wrong. :[

- Q: how to draw a crane hook on auto cad?

- Measure a crane hook then draw it. Even better, visit a manufacturer's web site and see if you can download one of their drawings for a hook.

- Q: 3years after I quit a job,I am once again looking toward the same field it's just that in my old job they helped me get a crane license when I left the job they kept my certification .How can i get that info without asking my old work for it,or would i have to take the course over?

- There is actually no such thing as a crane operators licence - you should tell your new employer that you had undertaken a course in your previous employment and were authorised by them to operate their cranes. The new employer will most likely then send you on another course and issue you with their operators authorisation. The authorisation from your old employer is not transferable to the new one so not having the certificate is not a major problem. It is however good practice for employees to receive a copy of the certificate for their own records.

- Q: the highest ranking American serviceman, at least in the so called prison camp

- no, he was brutally murdered

- Q: Ok I got these huge mosquito things in my house and found out they are crane flies. I got up this morning and there are several hanging from my ceiling on a long single strand of silk or web. Is this unusual? Its really weird.

- Probably just harvest man or a cellar spider making a web. You might have just mistaken them.

- Q: Im looking for more information on Overhead Cranes!?

- You would get lot of information on Over Head Cranes as permanently installed material handling equipment for various industries, if you google search under EOT CRANES. As I know, in steel industries their capacities can go up to 400 Tons. EOT cranes are electrically powered and electrically controlled systems. These cranes are categorized for maintenance application and production application. At times their design and construction are quite complicated specially those of production application such as Steel melting shop of steel plant.

- Q: What measures should be taken to make tower cranes stable?

- Increase deadweight and weight.Crane wire rope is phosphate coated steel wire, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope - double coating phosphating, phosphating coating to improve the wear resistance and corrosion resistance of steel wire that is not easy to wear and corrosion resistance is to improve the working life of the plain steel wire rope will be completely eliminated.

Send your message to us

Tower Crane TC6016 10 Ton Max Lifting Capacity

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords