TOBOND aluminum ceiling with accessories

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

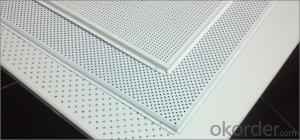

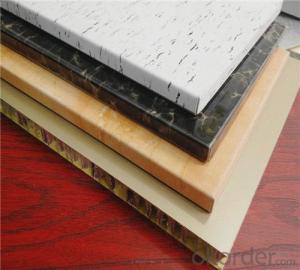

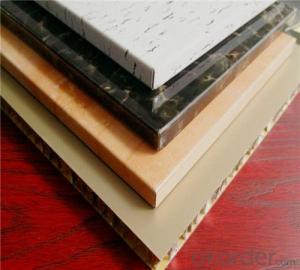

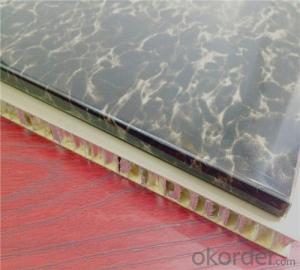

TOBOND Aluminium Ceiling

TOBOND Aluminium Ceiling are made of high quality aluminium sheet with excellent surface coating. It is widely used for indoor ceiling designs and public places ceiling.

TOBOND Aluminum Ceiling is with prime performance of economic efficiency, environment friendly and flexible installation. The series include plates of various sizes, all of which can be combined alternatively to make abundant effects.

TOBOND Aluminum Ceiling Application

widely used in commercial building, shopping mail, hotel, bank;

Used in restaurants, supermarkets, bank,, museums, hospital, sport centers, railway station , metro station and airport and other public places.

Mainly used in project for big area with fireproof requirements, such as ,stores, hospitals and so on.

TOBOND Aluminium Ceiling Panel Material: : Aluminum Alloy

STANDARD SIZE OF TOBOND Aluminium Ceiling

Series | Thickness | Panel Size | Hole Size | Surface Treatment | Color |

600*600mm Aluminium Ceiling | 0.5mm 0.6mm 0.7mm 0.8mm | 600*600mm 600*1200mm | Φ1.8 Φ2.3 Φ2.5 Φ3.0

| PVDF Painting/ Powder Coating/ PE Roller Coating/ PVDF Roller Coating | Pure white Milky white Color for option |

300*300mm Aluminim Ceiling | 0.5mm 0.6mm 0.7mm 0.8mm | 300*300mm 300*600mm | PVDF Painting/ Powder Coating/ PE Roller Coating/ PVDF Roller Coating |

Pure white Milky white Color for option | |

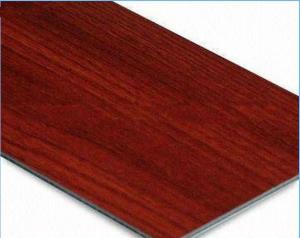

3D Home Decora Aluminium ceiling | 0.5mm 0.6mm 0.7mm 0.8mm | 300*300mm | 3D Heat transfer/ Roller painting/ | Various Design for option | |

Note: Custom’s size can be product on request. | |||||

- Q: Do you have a board on the back of an aluminum - plastic panel for exterior decoration and advertising

- With a triangular iron welding frame, outsourcing light box cloth on it.

- Q: What is the difference between stretching aluminum and hot-rolled aluminum? What is the concept of stretching aluminum?

- There is also a pre-stretched aluminum plate is relatively hard aluminum alloy (there are several grades), is in the production process to increase the stretch of this process, in order to eliminate the aluminum plate stress and strengthen the flatness of it.

- Q: Aluminum-plastic plate and aluminum plate which is cheap under the specific price instructions

- Qualified aluminum-plastic panels are generally in the range of 50-150 yuan per square meter. Aluminum plate is generally 80-600 yuan per square meter.

- Q: What are the characteristics and uses of aluminum-plastic panels?

- , And overcome the lack of the original composition of materials, and then get a lot of excellent material properties. Features: colorful decorative, weather, corrosion resistance, resistance to fire, moisture, moisture, noise, heat, Light, easy to shape, easy to install and other characteristics.

- Q: I want to open a small aluminum-plastic plate factory, how much money

- Production of aluminum-plastic board products, the need for pretreatment, painting, composite three sets of equipment, this down 800,000 on it, if it is a small factory, then you can find third-party manufacturers to paint, you can only on the composite line, so Single equipment 50 million enough.

- Q: Aluminum-plastic curtain wall construction in winter, with the real paste can you?

- Since it is aluminum-plastic curtain wall construction, then in accordance with the relevant requirements, should be used dry hanging practice,

- Q: Do you want to install aluminum alloy doors and windows on the external wall?

- You want to open a single door and window, you can press a full protection King Kong screen window

- Q: OKorder aluminum-plastic plate how much money, a little better, do with the external walls

- Outer Fluorocarbon aluminum-plastic board generally 90-160 yuan / square meters, depending on the level of the floor and how much use of aluminum-plastic panels, four or more recommendations with 4MM thick / 0.4MM aluminum, about 120 yuan / square Meter. Six or more best with the national standard plate 4MM thick / 0.5MM aluminum, about 145 yuan / square meter.

- Q: China where auspicious aluminum-plastic plate manufacturers? I have a lot of aluminum plastic panels.

- In China's words there is no auspicious aluminum-plastic plate manufacturers

- Q: What is good for plastic and plastic?

- General cooked rubber is more tough, raw rubber is not high temperature, the melting point is low, the melting point of 80 degrees or so, poor elasticity, fragile. Sika high temperature, melting point of about 120 degrees, better elasticity. , Softer for the cooked rubber.

Send your message to us

TOBOND aluminum ceiling with accessories

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords