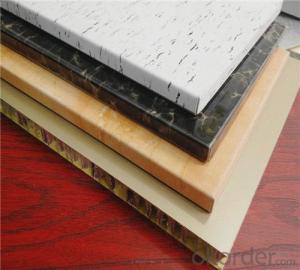

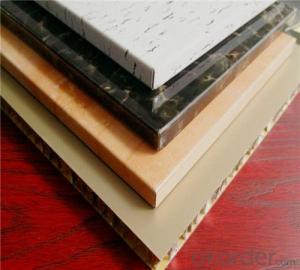

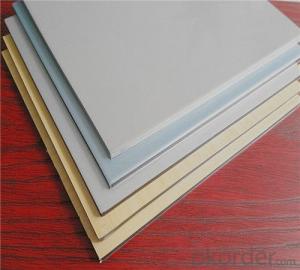

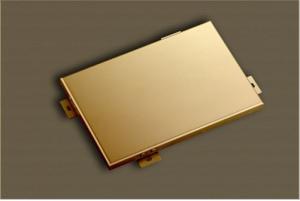

TOBOND aluminium composite panel/ metal panel/metal decorative panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

Size:1220*2440*5mm

TOBOND ACP Application

Outer wall cladding, curtain wall.

Redecoration of old buildings outer-wall.

Balconies, indoor partitions.

Units wall cladding

Advertisement signboard

Kitchen and bath room ceiling

Kitchen Cabinet surfacing decoration

Industrial Usage, Vehicle bodies.

STANDARD SIZE OF TOBOND ACP

Series | Coating | Usage | Panel Thickness | Panel Size(mm) |

PVDF Plus Outdoor Panel | PVDF | Exterior Wall Cladding | 4mm /3mm | 1220*2440 1220*2900 |

Indoor panel | Polyester | Interior Decoration/ Advertisement board | ||

Fireproof panel | PVDF/Polyester | Exterior Wall Cladding/Interior Decoration | ||

Special Size For Option | 6mm/5mm | 1250*2900 1500*2900 1500*5800 | ||

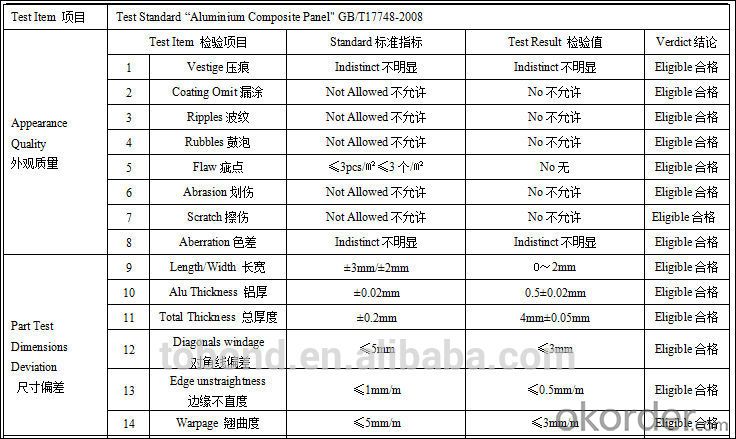

TEST REPORT FOR TOBOND ALUMINIUM COMPOSITE PANEL

|

- Q: Who prawn know that there is no aluminum plate factory in Shenyang it? What is the best brand and contact phone, thank you first, huh, huh

- Window of the future, Huayuan, Walter Thai, Yali Tai, Hua Tian, seven color and so on.

- Q: Can aluminum plate prevent radiation?

- Depends on the installation method, not directly put aluminum, aluminum can also be a role in the ground. Grounding is to connect the aluminum plate with the earth, so that the electromagnetic waves on the aluminum plate will be absorbed into the power of aluminum and flow to the ground, if not ground will produce the other side of the aluminum field, is tantamount to go through. In fact, grounding is very simple, if the installation of metal screws directly with the aluminum contact, but also with the cement wall contact can be considered ground, although not a good grounding. If the wall is wood or the like insulation material can not, then there is a screw, if it is the kind of hole in the wall into the plastic sleeve is not enough, because the plastic insulation.

- Q: Aluminum and aluminum plate What is the difference between ah

- The same thickness and specifications of the case of aluminum than aluminum-plastic plate weight, the price is generally higher than the aluminum plate. 2.5mm aluminum veneer to see, polyester or fluorocarbon, aluminum material, processing drawings, n is often flat in the 250 or so, aluminum-plastic plate, depending on the thickness of aluminum, the type of plastic, etc. Wall panels 40 yuan a square, the external walls of 100 yuan per square aluminum and aluminum-plastic plate installation is the same, but the aluminum plate is processed to a good job to the site, and aluminum-plastic plate to the site after processing and molding, aluminum-plastic plate manufacturers The site will generally have. There is a part of the details please contact the steel E station

- Q: Dry hanging stone, aluminum-plastic board two kinds of external wall decoration use and maintenance costs, investment costs, the applicability of the two materials decorative effect construction speed

- High cost of stone maintenance is simple and easy to use, the speed is slightly slower

- Q: Analysis of why the surface of aluminum-plastic plate deformation, from the drums

- Casually in which city in the circle, are not difficult to find some aluminum-plastic plate surface deformation, from the drums of those big unpleasant works. Small facade renovation works on this phenomenon, large high-rise buildings also have this phenomenon. In the construction, the emergence of such a quality problem, we have considered the quality of the plate itself; later, after we focus on the analysis found that the main problem lies in the paste sheet of aluminum-plastic plate, followed by aluminum The quality of the board itself. Dealers often provide us with aluminum-plastic plate construction process, the recommended use of grass-roots materials are mainly high-density board, woodworking board, etc. In fact, such materials used in the outdoor, its life is Very fragile, after the wind, sun, rain, will inevitably produce deformation. Since the grass-roots materials are deformed, then as the surface of the aluminum-plastic plate that is not deformed? Can be seen, the ideal outdoor base material should be After the rust treatment of angle steel, square steel pipe to form a skeleton is better.If the conditions permit, then use aluminum as a skeleton is more ideal. This type of metal material produced skeleton, the cost is not higher than the wood keel, high density Many, can really guarantee the quality of the project.

- Q: OKorder 3M glass curtain wall adhesive tape and aluminum-plastic plate Lvkou Ban and aluminum veneer special double-sided tape where there?

- US 3M company in OKorder designated agent 3M tape and glue labels and other products distribution and double-sided tape cutting and precision cross-forming! My company's tape has a professional curtain wall with double-sided adhesive.

- Q: Home decoration, aluminum-plastic board in general how thick ah?

- Size is generally 1220 * 2440

- Q: Aluminum slab plate and aluminum-plastic plate ceiling approach is not the same

- Practice is basically the same, the aluminum plate is the metal frame

- Q: What is the size of the general aluminum-plastic board?

- Thickness is generally 4MM, also a dozen silk.

- Q: Is there a kind of wall called aluminum?

- The plate is slightly thicker than the fire board, the surface is a thin layer of aluminum, the bottom is synthetic yarn.

Send your message to us

TOBOND aluminium composite panel/ metal panel/metal decorative panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords