nano aluminum composite panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

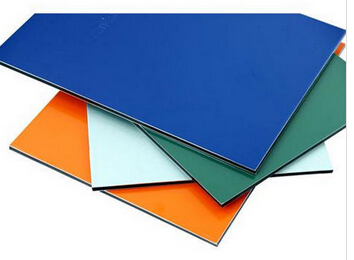

Material of Aluminum composite panel

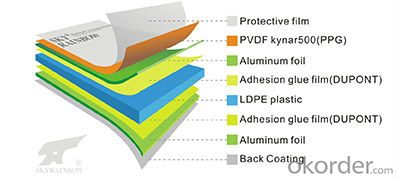

A) Front : aluminium alloy sheet coated with PleochromaticPVDF paint on surface B) Core: nontox low density polyethylene C) Back: aluminium alloy sheet coated with polyester resin painting D) Surface coating thickness: 32μ±1μ E) Aluminium alloy: 3003 H24 F) Sheet thickness: 0.3mm,0.4mm,0.5mm |  |

Specification of aluminum decorative panels

| | |

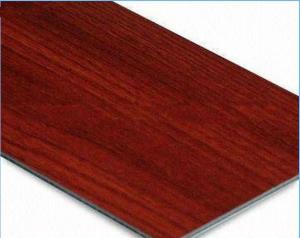

| Surface | PE or PVDF,Nano,Brushes,Mirror,Marble Look,Wooden Look,Glossy |

| Core | LDPE, Fireproof |

| Back Side | Primer or Mill Finish |

| Aluminum thickness | 0.06-0.50mm |

| Panel thickness | 2mm, 3mm, 4mm, 5mm,6mm |

| Width | 1220mm, 1250mm, 1500mm,1550mm,Less Than 1570mm |

| Length | Any Length Less Than 6000mm |

Advantage of aluminum decorative panels

1) Excellent fireproof performance & heat insulation, sound insulation

2) Weather resistance, high strength, high plasticity

3) , good impact resistance, quakeproofs performance and reducing buildings load

4) Various colors , convenient installation, easy maintenance

5) Widely used in galleries, exhibitions, saloons, stores, offices, banks, hotels, restaurants and apartments etc

- Q: Kitchen and aluminum plate or aluminum plate? What is the difference between the integrated ceiling and the two of them? These three kinds of price?

- Certainly with aluminum buckle plate, because his life is relatively long, aluminum-plastic plate, with a 3.5 years to die, the effect is obvious.

- Q: Aluminum-plastic curtain wall construction in winter, with the real paste can you?

- Curtain wall, there is no wet paste. The The Wet paste is the practice of decoration, used in outdoor, because the outdoor weather conditions are relatively poor, generally about two years will lead to hollowing, off the board and other serious problems! Do not talk about winter or summer construction.

- Q: LED lights are normal, why the aluminum plate is also charged. And is 220V of electricity. Really scary.

- Check the line, it may be aluminum-plastic plate cut wire, or nail pierce the wire, resulting in aluminum-plastic board charged.

- Q: Aluminum-plastic board seamless dry hanging how to make

- Each board unit or in accordance with the normal practice to do,

- Q: Plywood attached to the board how to deal with degumming? What kind of glue how to deal with?

- Aluminum-plastic composite panels are made of multi-layer composite material, the upper and lower layers of high-purity aluminum alloy plate, the middle of non-toxic low-density polyethylene (PE) core board, the front also paste a protective film. For outdoor, aluminum-plastic panels coated with fluorocarbon resin (PVDF) coating, for the interior, the front can be non-fluorocarbon resin coating.

- Q: My family in Foshan Chancheng, home kitchen ceiling to change! Do not know the aluminum plate is good, or aluminum-plastic plate is good? How much are their prices and materials?

- Personal personal advice you do aluminum plate, because the aluminum plate is to use glue attached to the plywood, which is related to the quality of the glue, followed by the paste technology is also related to the three also with the splint of the ups and downs, and finally Ask you still ready to replace it? If sure, that aluminum plate will not bring you trouble, if not change, it is still aluminum plate, the time is better. The price of a business can be imagined

- Q: On the report of the project price per square meter engineering requirements is to use 50 * 5 angle iron keel with 4mmA grade aluminum-plastic plate dry hanging

- Structural adhesive material must be neutral silicone sealant, its performance must meet the requirements of the construction of silicone structural sealant GB16776 (silicone sealant must be used within the validity period) fasteners are mainly screws and self-tapping , Its material is generally stainless steel or aluminum products, fasteners to meet the design requirements, and the quality to meet the national norms and the relevant standards. Main tools (tools): welding machine, profile cutting machine, pistol drill, theodolite, level, rivet gun, self-drilling and milling machine

- Q: Aluminum panels are used in what areas, can not be more detailed.

- The aluminum-plastic panels were first developed by the German company Aiusingen and later improved by Forken and Aloca. 90 years later, the product quality gradually stable, reached a high level. As the aluminum-plastic plate is composed of two different materials (metal and non-metallic), it retains the original composition of materials (metal aluminum, non-metallic polyethylene plastic) the main features, but also to overcome the lack of raw materials , And then get a lot of excellent material properties. Such as luxurious and beautiful, colorful decorative; weathering, corrosion resistance, impact resistance, fire, moisture, heat insulation, sound insulation, light resistance; light, easy processing, easy handling, quick construction and other characteristics. These properties for the aluminum-plastic plate opened up a broad application prospects.

- Q: Anhui where the production of aluminum veneer aluminum PE board PP PP

- Around the Zhejiang, Henan, Shandong several provinces have the corresponding manufacturers can contact.

- Q: Ordinary decorative aluminum-plastic composite plate with the nominal thickness of aluminum is how much

- Common is 3mm / 4mm / 5mm / 6mm, the specific size of the two sides agreed to supply and demand. Deviation of about 0.2mm.

Send your message to us

nano aluminum composite panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords