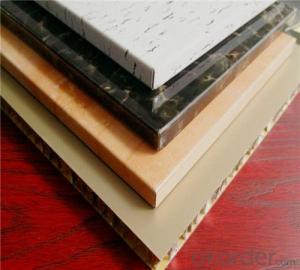

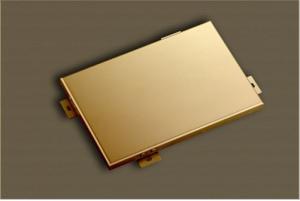

TOBOND interior metal wall panel/ metal cladding/metal wall tiles/aluminium composite panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

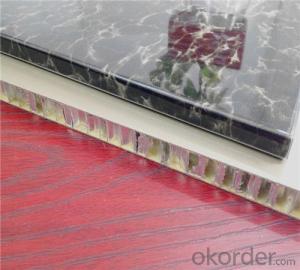

TOBOND PVDF plus Aluminium Composite Panel is special metal surface wall cladding material, compounded with superior aluminum and LDPE Plastic.

Comparing to traditional metal panel, TOBOND ACP is with prime performance of economic efficiency, environment friendly and flexible installation.

ADVANTAGES OF TOBOND ACP

High strength, easy maintenance, 20 years not color fade.

Easy fabrication and installation.

Good Impact Resistance.

Light weight and rigid, reducing buildings load, good performance for quakeproof.

Good Smoothingness.

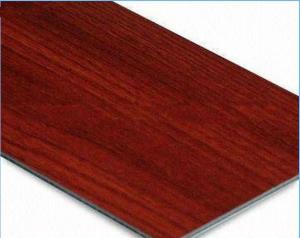

Various color and size for option.

TOBOND ACP Application

Outer wall cladding, curtain wall.

Redecoration of old buildings outer-wall.

Balconies, indoor partitions.

Units wall cladding

Advertisement signboard

Kitchen and bath room ceiling

Kitchen Cabinet surfacing decoration

Industrial Usage, Vehicle bodies.

STANDARD SIZE OF ACP

Series | Coating | Usage | Panel Thickness | Panel Size(mm) |

PVDF Plus Outdoor Panel | PVDF | Exterior Wall Cladding | 4mm /3mm | 1220*2440 1220*2900 |

Indoor panel | Polyester | Interior Decoration/ Advertisement board | ||

Fireproof panel | PVDF/Polyester | Exterior Wall Cladding/Interior Decoration | ||

Special Size For Option | 6mm/5mm | 1250*2900 1500*2900 1500*5800 | ||

Proceeding Noticed

Portage: panel must be uplifted with its four borders at the same time during portage, do not drag and whop for fear scraping surface of the panel.

Storage: panel must be stored in cool dry place, and placed on flat surface.

Notching; if notching with notching equipment or gong equipment, using milling cutter with half round head≥90 degree. When notching, pls leave 0.2—0.3mm thickness plastic core materials bending with aluminium sheet to increase intension and tenacity, otherwise aluminium sheet may rupture or coating crack.

Bending: forcing equably when bending, molding one-off, do not bend again and again, or Aluminium panel may rupture.

Arcing Machining: using professional bending equipment to machining, forcing inchmeal to make the panel reaching bending radian needed. Do not bending one-off.

Batch: same color panel from different batches may have chromatic aberration, contrast process of chromatic aberration should be added if selling or using panels with different batches panels. Panels can be placed on a plane only there may be visual chromatic aberration.

Installation direction: panels must be install in same direction.

Ripping film: the protective film should be ripped away within 45 days after installation, to avoid survivors left.

Cleaning: clear the panel with water, scours or alcohol over98% with soft sponge. Do not use Chemical Solvents.

- Q: I have thousands of pounds of aluminum slab scrap where the acquisition, how much money a kilogram

- 5 to 6 dollars a pound.

- Q: Do you have a board on the back of an aluminum - plastic panel for exterior decoration and advertising

- So do not have to consider the aluminum-plastic plate, because the cheap aluminum plate is certainly more expensive than wood

- Q: What are the characteristics and uses of aluminum-plastic panels?

- It retains the main characteristics of the original constituent materials (aluminum alloy sheet, non-metallic polyethylene plastic)

- Q: How will the aluminum-plastic plate be connected?

- Plastic welding (only for PE core material)

- Q: By the radiator, affixed to the wall of the aluminum-plastic plate afraid of high temperature by radiator, affixed to the wall of the aluminum-plastic plate afraid of high temperature

- Hello, aluminum-plastic plate with high temperature, corrosion-resistant advantages, but a long time baking, will be relatively reduced service life. Hope can help you.

- Q: Ceiling now we all use what brand, almost all aluminum-plastic plate it

- Not just aluminum-plastic plate, you can go to the building materials market to see, such as Hangzhou's star Meikailong (Jin Mao shop) there are a lot of brands, you can go and see!

- Q: Sub-white aluminum-plastic door with a white aluminum side, how? The effect is good?

- The easiest way is to directly on the white aluminum-plastic plate directly attached to a layer of black aluminum plate. Since you have done aluminum-plastic board layer, that grass-roots flatness should not be a problem! We often do shop strokes, spray paint with the car, will not fall, the premise is to clean up the original level, remember that is spray, not brush.

- Q: Aluminum slab plate and aluminum-plastic plate ceiling approach is not the same

- Aluminum plate is made of pre-formed, and a matching keel and boom and other accessories. Installation is more convenient. And aluminum plate to do ceiling materials, the need for on-site processing and molding, and arbitrariness is relatively strong, so the specific approach is still different of

- Q: My company has 20,000 square meters of color steel plate need to be cleaned. 150,000 square aluminum plate needs cleaning, may I ask which cleaning company in Guangzhou more professional? Which cleaning company is cheap, cleaning effect is better?

- Guangzhou exterior wall cleaning company | Guangzhou facade cleaning company | Guangzhou facade cleaning company | Guangzhou facade cleaning company | Guangzhou city furniture cleaning company | Guangzhou facade demolition company | Guangzhou facade cleaning company | Guangzhou billboard cleaning Guangzhou City, Guangdong Province, Guangzhou City, Guangzhou City, Guangdong Province, Guangzhou City, Guangzhou City, Guangzhou City, Guangzhou City, Guangzhou City, Guangzhou City, Guangzhou City, Guangzhou City, Guangzhou City, Wall Cleaning & Cleaning Company | Guangzhou Exterior Installation Co., Ltd. | Guangzhou Exterior Repair Company | Guangzhou Jia Leqing Cleaning Service Co., Ltd.

- Q: Heroes are good, I would like to know that aluminum-plastic plate is one side of the aluminum, one side of the kind of material is plastic? About three or four millimeters thick! Is it done with this board?

- Aluminum-plastic plate is an aluminum-plastic composite board. Is a layer of plastic (polyethylene or polyvinyl chloride) and two layers of aluminum composite made of aluminum skin appearance of fluorocarbon coating, the general thickness of 3-4 mm

Send your message to us

TOBOND interior metal wall panel/ metal cladding/metal wall tiles/aluminium composite panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords