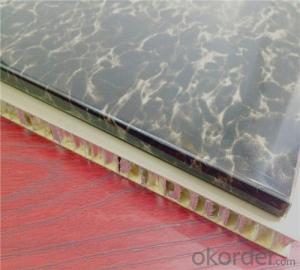

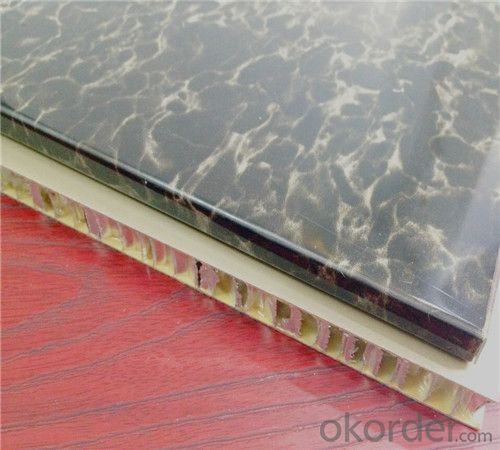

Aluminum sandwich panel / TOBOND wall panel

- Loading Port:

- Zhuhai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

TOBOND PVDF plus Aluminium Composite Panel is special metal surface wall cladding material, compounded with superior aluminum and LDPE Plastic.

Comparing to traditional metal panel, TOBOND ACP is with prime performance of economic efficiency, environment friendly and flexible installation.

Panel Size:1220*2440(mm)

TOBOND ACP Application

Outer wall cladding, curtain wall.

Redecoration of old buildings outer-wall.

Balconies, indoor partitions.

Units wall cladding

Advertisement signboard

Kitchen and bath room ceiling

Kitchen Cabinet surfacing decoration

Industrial Usage, Vehicle bodies.

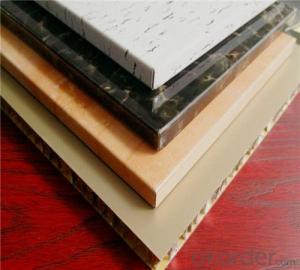

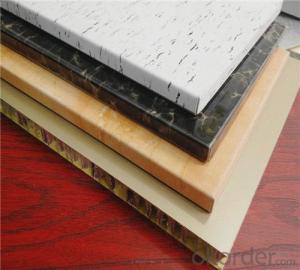

Color Chart:

STANDARD SIZE OF TOBOND ACP

Series | Coating | Usage | Panel Thickness | Panel Size(mm) |

PVDF Plus Outdoor Panel | PVDF | Exterior Wall Cladding | 4mm /3mm | 1220*2440 1220*2900 |

Indoor panel | Polyester | Interior Decoration/ Advertisement board | ||

Fireproof panel | PVDF/Polyester | Exterior Wall Cladding/Interior Decoration | ||

Special Size For Option | 6mm/5mm | 1250*2900 1500*2900 1500*5800 | ||

Proceeding Noticed

Storage: panel must be stored in cool dry place, and placed on flat surface.

Notching; if notching with notching equipment or gong equipment, using milling cutter with half round head≥90 degree. When notching, pls leave 0.2—0.3mm thickness plastic core materials bending with aluminium sheet to increase intension and tenacity, otherwise aluminium sheet may rupture or coating crack.

Arcing Machining: using professional bending equipment to machining, forcing inchmeal to make the panel reaching bending radian needed. Do not bending one-off.

Installation direction: panels must be install in same direction.

- Q: I made aluminum-plastic curtain wall decoration for 6 years, this year out of their own company to start the contractor, but suffer from no business, ran a lot

- Business is the key to a business, generally rely on the time to accumulate, with money public relations, product quality and service, not to come, you can only run the current run, adhere to the victory!

- Q: Aluminum plate 50 wire thickness what it means

- 50 silk 4mm thick aluminum-plastic curtain wall

- Q: 2017 aluminum-plastic board how the trend?

- Aluminum industry trend research report is through the aluminum plate industry market operation of many factors carried out by the investigation and analysis, grasp the aluminum plate industry market operation law, so the future development trend of aluminum industry characteristics, market capacity, competitive trends, sub-downstream market Demand trends and so on. First, the aluminum industry trends research report analysis of the main points include: 1) aluminum industry trends analysis. Through the analysis of the factors affecting the development of aluminum industry, the paper summarizes the characteristics of the overall operation trend of aluminum industry in the future; 2) predicts the development and trend of aluminum plate industry. Forecasting the development of production and its trends, which is the forecast of the supply of goods and its trends in the market; and 3) forecast the market capacity and change of the aluminum industry. Comprehensive analysis of the aluminum industry during the forecast production technology, product structure adjustment, forecast the demand for aluminum industry structure, quantity and trends. 4) forecast the aluminum market price changes. The price of the inputs and the sales price of the products are directly related to the profitability of the enterprises.

- Q: Reflective film mounted to the aluminum-plastic plate, just mounted on a very flat, a night arch on why

- Now find a stable quality of the manufacturers really is not easy, or things do not deal with the quality of the problem often, I have used problems, continuous change for several suppliers, and now stable in a lions company. I introduced to you, good service attitude, product quality trust, problems will be dealt with immediately.

- Q: Aluminum-plastic plate production line inverter has a specific role, can specifically say it?

- Automatic spraying equipment work process is through the conveyor chain will be sprayed into the high temperature oven, after a series of baking process so that the coating attached to the paint to be sprayed, and then sent by the transmission chain, the workers removed from the chain inspection, qualified Warehousing. Its electrical control system requirements can be adjusted according to different spray conveyor chain speed, in order to ensure adequate high temperature heating time, theoretically realized should be very simple, but because the conveyor chain is longer, the use of a single motor drag is very difficult, so the design Using two motors, which in turn a key issue is how to ensure that the two motor synchronization? Because if the synchronization will lead to the accumulation or breakage of the conveyor chain lead to the production can not be carried out, the three crystal inverter in the life of the speed of the death cycle control effectively solve the synchronization problem.

- Q: Japan Kobe Steel 5052 aluminum how much money a kilogram?

- The price of the total change, and easy to fake, about a few hundred it!

- Q: What is the cost of each material made by the bank's aluminum-plastic plate ceiling?

- Halo, you also figure, you'd better find professional Foshan water pan-gold aluminum plate.

- Q: Out of the balcony of the door sets, with the plywood bag to worry about the sun drying fade. Cracking, with aluminum-clad board package is not only good-looking, can you please help out an idea, thank you !!

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Belonging to a new type of building decoration materials.

- Q: How much is the bigger the better

- Not the bigger the better, according to the application site and construction process. Such as the interior wall facade decoration can not be too thick, generally aluminum thickness of 0.21 mm or less on the thickness of the. Such as facade high-rise, aluminum thickness must be thicker. So at least the wind pressure strength is better.

- Q: What is the difference between aluminum and aluminum curtain wall aluminum veneer? That cost is high!

- Composite aluminum is also known as aluminum composite panels,

Send your message to us

Aluminum sandwich panel / TOBOND wall panel

- Loading Port:

- Zhuhai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords