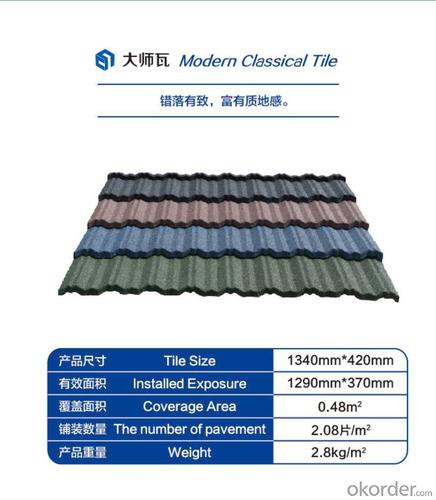

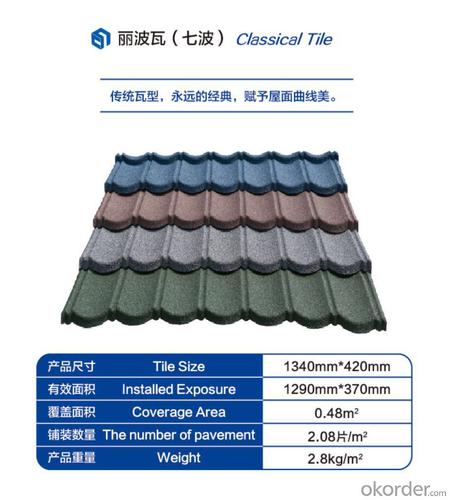

Stone Coated Roofing Sheet with New Design

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

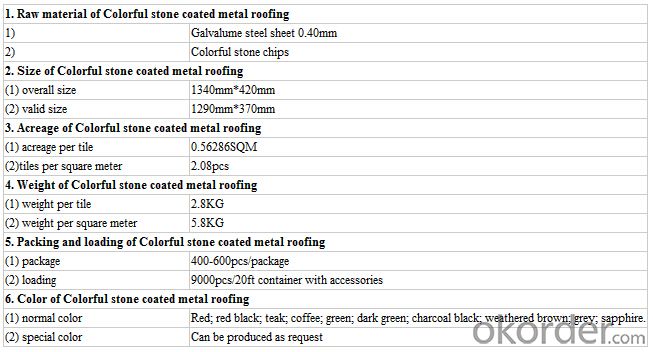

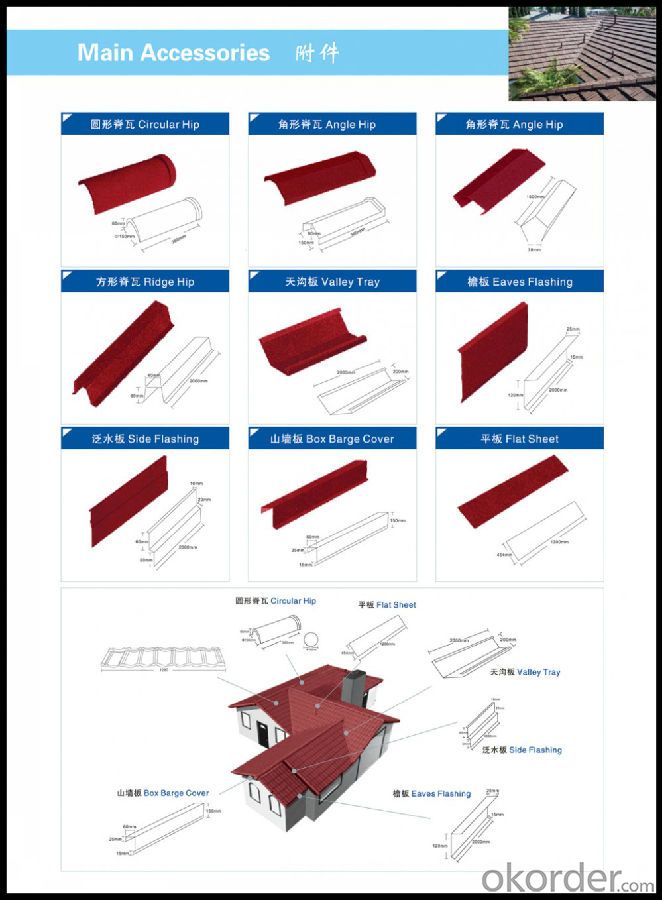

Product Introduction:

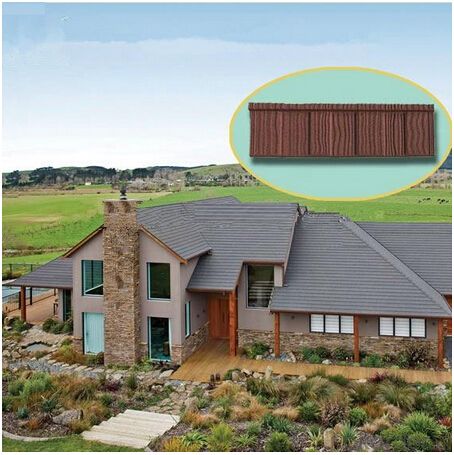

Color Stone Coated metal Roof is based on Al-Zn(Known as Zincalume or Galvalume steel)steel. The before and after protective film treatment, together With high precision pressure-shaped gravel ensure the roof to be the best roofing material. Coated With an alloy composed of Al 55%, Zn 43.4%,Si 1.6%, with Non-toxic acrylic adhesive and natural stone, Color Stone Coated metal Roof provides the advantages of long life, strength, durability and beauty.

Product Advantages:

1. Light weight.

To compare with the traditional ceramic tile, the weight of our metal roof tile is just 1/6 of it.

It is convenient to carry, store and use, so it can save the time and cost of installation.

2. Easy installation.

Metal roof tile is very light and it is easy to incise and cut off, so it is suitable for all kinds of buildings,

especially for the heavy grade roofs and towers.

3. Excellent durability.

High quality galvalume plates and natural stone chip coatings are characterized by their excellent

anti corrosion features which extends the life span of tiles for more than 30 years without fade.

4. Recyclable and Eco-friendly.

Metal roof tiles are galvalume based and have high recyclable content. Over 90% of the tiles are

recyclable,which makes it more economical.

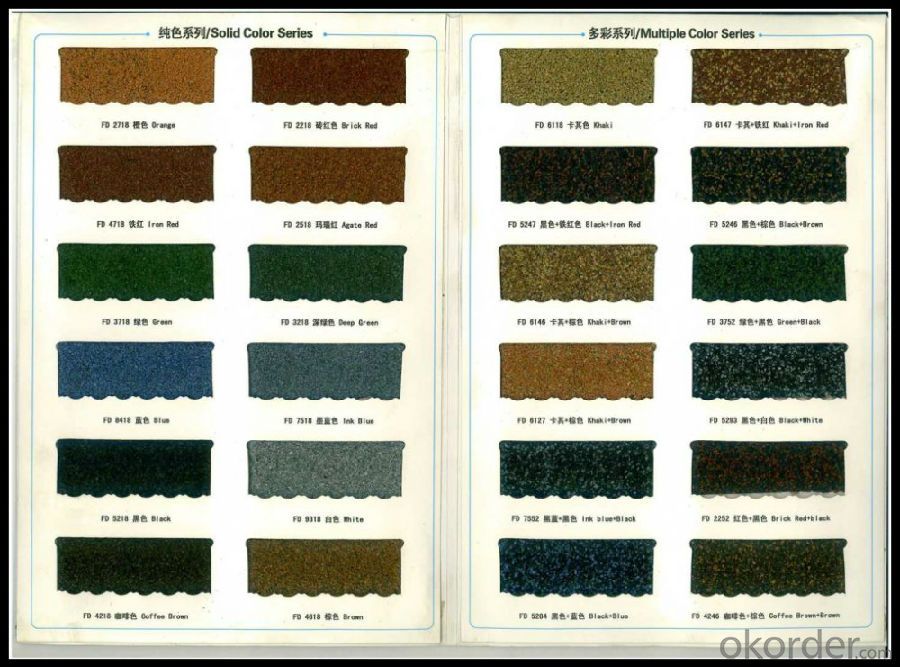

5. Beautiful appearance.

Rich color and variety types will bring a beautiful surface for your roof.

6. Earthquake resistance.

Earthquake can cause the infinite property loss, the more is because of the structure roof and the

weight of tile. Stone coated metal roof tiles are light and firm,they can lighten the building and won’t

easily cause damages to the under structures of the buildings in earthquakes.

7. Wind resistance.

Even metal tile just has the 1/6 of weight to the traditional tile,the scientific interlocking system design

techniques guarantee the roofing system more safety in the storms.

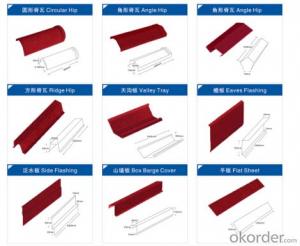

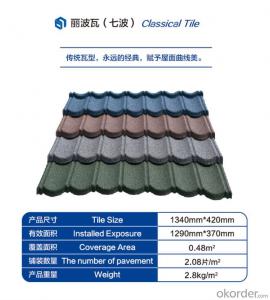

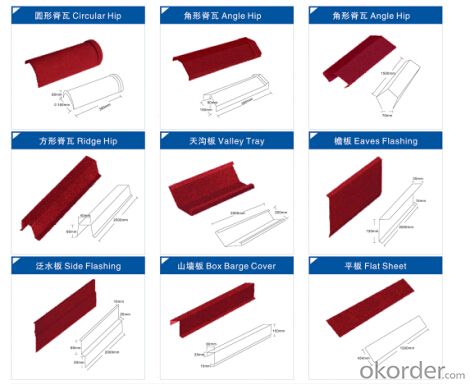

Product Specification:

FAQ:

Q: What's your payment?

A: T/T, L/C, etc.

Q: Can you offer samples?

A: Yes, we could offer according to customer's requirement.

Q: Can I check the quality before loading?

A: Yes, it will be better.

- Q: Answer: drawing wire and aluminum plate internal structure Thank you

- Brushed fire aluminum composite panel internal structure is: the surface of the drawing effect of aluminum substrate + fire core material + back with aluminum plate

- Q: Aluminum and aluminum plate What is the difference between ah

- Simply say that aluminum is pure metal, aluminum-plastic plate is only the surface of the metal (surface metal after treatment) and the middle of polyethylene plastic.

- Q: What are the materials for making aluminum-plastic panels?

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Belonging to a new type of building decoration materials.

- Q: Fire board 525 front line 38 thick, depth ≤ 600, aluminum plastic after the file water, FB-F09 edge of the price

- You did not understand, I did not understand.

- Q: I would like to ask the next aluminum plate, aluminum veneer and aluminum composite panels are three characteristics

- Aluminum plate is generally referred to as the thickness of 1.2mm below the aluminum plate.

- Q: What kind of material is made of aluminum-plastic plate?

- Material Aluminum: curtain wall board with material properties should be consistent with GB / T3880.2 requirements of the 3 × × × series, 5 × × × series or better corrosion resistance and mechanical properties of other series of aluminum alloy. Aluminum should be cleaned and chemically pretreated to remove oil, dirt and loose layers of natural formation from contact with air and form a layer of chemical conversion film to facilitate aluminum and coating and Solid bonding of the core layer. Coating: curtain wall coating material should be used weatherability excellent fluorocarbon resin, can also use other performance quite or more excellent material. Note 1: Polyvinylidene fluoride fluorocarbon resin (PVDF), which is excellent in weatherability, is widely used. However, pure PVDF resin should not be directly coated on aluminum, and some other materials should be added as appropriate to change its coating Performance, which constitutes the so-called 70% fluorocarbon resin. Note 2: 70% fluorocarbon resin, refers to the production of aluminum-plastic plate coating used in a variety of raw materials, PVDF resin raw materials accounted for 70%. As the paint is also a pigment and other components and fluorocarbon resin coating is usually a layer of non-fluorocarbon resin primer, so the total thickness of PVDF in the total coating of aluminum-plastic plate is about 25% to 45%. Core material: Ordinary curtain wall board material used in the material properties should be consistent with GB11115, GB11116, GB / T15182 or other corresponding national or industry standards.

- Q: Whether the aluminum plate is non-combustible material

- Can provide non-combustible grade aluminum composite plate material, but can not say that aluminum-plastic plate is non-combustible material.

- Q: I am here in Guangzhou, aluminum-plastic plate is made of high quality 4MM thick (aluminum thickness of not less than 0.4), thank you!

- Product thickness is generally 4 mm, aluminum plate aluminum and back aluminum regular manufacturers will arrange equal thickness of 0.40mm or 0.50mm, coating requirements for the fluorocarbon coating.

- Q: Is the aluminum-plastic board protective film toxic?

- Aluminum plastic plate life is short, good antioxidant capacity, are generally used in the door or store decoration, home improvement generally do not use aluminum-plastic plate. If you take into account the environmental protection, it is recommended to use your favorite panel and then brush on the favorite color.

- Q: What is the difference between the aluminum-plastic plate and the aluminum-plated plate?

- Aluminum-plastic plate is a chemically treated coating of aluminum as the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. Aluminum-plastic composite panels in the country has been widely used, belonging to a new type of building decoration materials. Aluminum-plastic plate can be cut according to the shape, specifications are relatively large. It is a new type of decorative material in recent years. It has fireproof, moistureproof, anti-static, sound and soundproof, light, water resistant, high temperature, no dust, corrosion, easy to clean, easy to install, Color soft and beautiful and other characteristics, more suitable for home use; aluminum slab plate is generally fixed specifications 300 * 300, there are 300 * 600 specifications. Aluminum-plastic panels are generally not used for the ceiling, it can be used for building facades, curtain wall panels, renovation of the old building renovation, interior walls and ceiling decoration, advertising signs, display stand, clean dust works. Aluminum slab is the third generation of ceiling materials metal ceiling in the crowd, the current market is also divided into several grades of aluminum slab: the first class of aluminum-magnesium alloy, also contains part of the manganese, the biggest advantage of the material is Good resistance to oxidation, and because of the addition of the right amount of manganese, the strength and stiffness have improved, is the best material for the ceiling. The second type of aluminum-manganese alloy, the strength and stiffness of the plate is slightly better than the aluminum-magnesium alloy, but the antioxidant capacity of a slight shortage of the third type of aluminum alloy, the plate contains manganese, magnesium less, so its strength and stiffness are obvious Lower than the aluminum-magnesium alloy and aluminum-manganese alloy, antioxidant capacity in general.

Send your message to us

Stone Coated Roofing Sheet with New Design

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords