TINPLATE Of Good Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5; DR8 - DR10;

Annealing: BA & CA

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

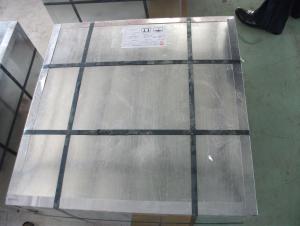

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Application: widely used in every kinds of packing cans,such as tea packaging cans, painting packaging cans, chemical packaging cans and dry food packaging cans; and also mechanical parts

Both Prime and Second Quality Are Available!!!

- Q: What are the different types of tinplate finishes available?

- There are several different types of tinplate finishes available, including bright finish, stone finish, matte finish, and lacquered finish. Each finish has its own unique appearance and characteristics, allowing for a variety of options when it comes to tinplate products.

- Q: How to quickly distinguish tinplate and ordinary substrate iron?

- Tinplate is the substrate, iron tin plating, tin bright, the substrate is dark, the substrate for a few days rust, and the two put together, the difference is great.

- Q: How is tinplate recycled and what are its recycling rates?

- Tinplate is recycled through a process called "tinplate recycling" where it is collected, sorted, and melted down to create new products. The recycling rates of tinplate vary depending on factors such as regional recycling infrastructure, collection efforts, and consumer awareness. However, on average, tinplate has a relatively high recycling rate of around 80-90% in many developed countries.

- Q: What are the advantages of using tinplate for stationery?

- One advantage of using tinplate for stationery is its durability. Tinplate is known for its strength and resistance to corrosion, making it highly durable and long-lasting. This ensures that stationery items made from tinplate, such as pencil cases or storage tins, can withstand regular use and maintain their functionality over time. Additionally, tinplate is also a versatile material that can be easily shaped and molded into various designs, allowing for creative and aesthetically pleasing stationery products.

- Q: How is tinplate coated with anti-tarnish materials?

- Tinplate is coated with anti-tarnish materials through a process called passivation. This involves applying a thin layer of protective coating onto the tinplate surface to prevent oxidation and tarnishing. The coating can be made from various materials such as organic compounds or inorganic substances like chrome or zinc, which create a barrier against moisture and other corrosive elements. This helps to maintain the aesthetic appeal and durability of the tinplate over time.

- Q: Can tinplate packaging be used for pet care products?

- Yes, tinplate packaging can be used for pet care products. Tinplate is a durable and versatile material that can protect and preserve pet care products such as food, treats, and grooming items. It is resistant to corrosion, tampering, and can be easily customized with attractive designs and branding. Additionally, tinplate is recyclable, making it an environmentally friendly choice for pet care packaging.

- Q: Can tinplate packaging be used for gift items?

- Yes, tinplate packaging can be used for gift items. Tinplate is a durable and versatile material that can be shaped into various sizes and designs, making it suitable for packaging different types of gifts. Additionally, tinplate packaging offers a unique and attractive appearance, enhancing the overall presentation of the gift.

- Q: What are the advantages of using tinplate packaging?

- There are several advantages of using tinplate packaging. Firstly, tinplate is highly durable and provides excellent protection to the packaged goods, ensuring their safety during transportation and storage. Secondly, tinplate has a high resistance to corrosion, which helps to maintain the quality and freshness of the products for a longer period of time. Additionally, tinplate packaging is lightweight, which reduces transportation costs and makes it easier for consumers to handle. Moreover, tinplate is a sustainable and recyclable material, making it an environmentally friendly choice. Lastly, tinplate packaging is versatile and can be easily shaped, printed, and decorated, allowing for attractive and eye-catching designs, enhancing product visibility and brand appeal.

- Q: What are the common surface coatings for tinplate?

- The common surface coatings for tinplate include tin-free steel, electrolytic tinplate, tin-free steel with organic coatings, and tinplate with lacquered coatings.

- Q: How does tinplate contribute to the safety of toys?

- Tinplate contributes to the safety of toys by providing a durable and non-toxic material that is resistant to corrosion and can withstand rough handling. It helps prevent sharp edges and ensures that toys do not break easily, reducing the risk of injuries during play. Additionally, tinplate is often used in the packaging of toys, offering a protective barrier that prevents contamination and prolongs the shelf life of the product.

Send your message to us

TINPLATE Of Good Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords