TIN PLATE Of Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5; DR8 - DR10;

Annealing: BA & CA

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

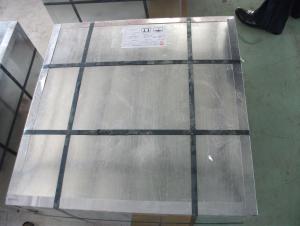

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Application: widely used in every kinds of packing cans,such as tea packaging cans, painting packaging cans, chemical packaging cans and dry food packaging cans; and also mechanical parts

Both Prime and Second Quality Are Available!!!

- Q: What are the main challenges in tinplate coating?

- The main challenges in tinplate coating include ensuring uniform and consistent coating thickness, preventing defects such as pinholes and streaks, managing adhesion between the tin and base metal, and addressing environmental concerns related to the use of certain chemicals and waste disposal. Additionally, maintaining high production speeds while maintaining quality standards and reducing costs poses another challenge in tinplate coating.

- Q: How does tinplate affect the overall cost of packaging production?

- Tinplate can significantly impact the overall cost of packaging production due to its higher price compared to other materials such as aluminum or plastic. Its production, coating, and transportation costs can add up, making it more expensive for manufacturers. However, tinplate offers excellent durability, protection, and aesthetic appeal, which can enhance the value and marketability of the packaged product. Ultimately, the cost-effectiveness of tinplate packaging depends on factors like the specific product, target market, branding strategy, and overall budget.

- Q: How is tinplate cut and formed into different shapes?

- Tinplate is typically cut and formed into different shapes through a process known as stamping or die-cutting. This involves the use of specialized machines that use sharp dies or punches to cut the tinplate into the desired shape. The tinplate is fed into the machine, and the die or punch is pressed onto it with sufficient force to cut or shape it. This process allows for precise and efficient production of various tinplate shapes, such as cans, containers, or components for various industries.

- Q: How to quickly distinguish tinplate and ordinary substrate iron?

- Tinplate is the substrate, iron tin plating, tin bright, the substrate is dark, the substrate for a few days rust, and the two put together, the difference is great.

- Q: How is tinplate used in the wine and spirits industry?

- Tinplate is commonly used in the wine and spirits industry for packaging purposes. It is often used to make metal cans, closures, and caps for wine and spirits bottles. Tinplate provides a protective and durable barrier against light, air, and moisture, ensuring the quality and shelf life of the product. Additionally, the smooth and shiny surface of tinplate enhances the overall aesthetics of the packaging, giving it a premium and sophisticated look.

- Q: What are the benefits of using tinplate for paint cans?

- Tinplate offers numerous benefits for paint cans, including its excellent durability, resistance to corrosion, and ability to maintain product quality by providing a protective barrier. Additionally, tinplate is recyclable, making it a sustainable choice for packaging.

- Q: Can tinplate be used for high-speed packaging lines?

- Yes, tinplate can be used for high-speed packaging lines. Tinplate, which is a thin steel sheet coated with a layer of tin, offers excellent strength and durability, making it suitable for fast-paced packaging operations. Its smooth surface allows for easy printing and labeling, while its corrosion resistance ensures the longevity of packaged goods. Additionally, tinplate's ability to withstand high temperatures and its recyclability make it a popular choice for high-speed packaging lines in various industries such as food and beverage.

- Q: What are the different coatings used on tinplate?

- There are several different coatings used on tinplate, including tin-free steel (TFS), electrolytic tinplate (ETP), tin-free steel chromium coated (TFS Cr), and tinplate with an organic coating (lacquered tinplate). These coatings serve various purposes such as providing corrosion resistance, enhancing the appearance, and improving the overall durability of the tinplate.

- Q: What are the main applications of tinplate in the sports equipment industry?

- Tinplate is commonly used in the sports equipment industry for various applications such as packaging for tennis balls, protective coatings for golf clubs, and components for hockey sticks. Its corrosion-resistant properties and ability to maintain shape and durability make it an ideal material for ensuring the longevity and performance of sports equipment.

- Q: How is tinplate used in the pet food industry?

- Tinplate is commonly used in the pet food industry for packaging purposes. It provides a durable and protective barrier against moisture, light, and oxygen, ensuring the quality and freshness of pet food. Tinplate cans are widely used to package wet pet food products, providing a long shelf life and easy storage for pet owners.

Send your message to us

TIN PLATE Of Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords