Tinplate For Aerosol Can-CHBA

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Tons~25 Tons m.t.

- Supply Capability:

- 40000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

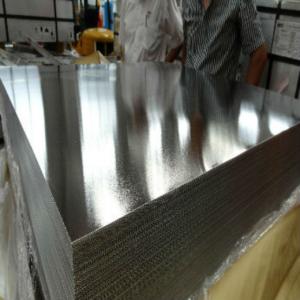

General information of Tinplate for Aerosol Can

|

Steel Type |

SPCC |

|

Temper (BA&CA) |

T1~T5, DR8 |

|

Coating |

2.8~8.4g/m2 |

|

Thickness & Tolerance |

0.15~0.5mm (Tolerance:±0.01mm) |

|

Width & Tolerance |

600~1000 mm(Tolerance: +2/-0mm) |

|

I.D |

508 MM |

|

Coil Weight |

3~10 MT |

|

Passivation |

311 |

|

Oiling |

DOS |

|

Surface Finish |

Bright ,Stone ,Silver ,Matte |

|

Min Order |

25 Tons for 1 20 feet FCL |

|

Package |

Seaworthy Export Standard Wooden Pallet |

|

Standard Available |

GB/T2520-2000, JIS G3303, ASTM A623, BS EN10202 |

|

Lead Time |

35 days after receiving buyer's original L/C or Prepayment |

|

Special specifications are available on customers' requirements. | |

Technical data of Tinplate for Aerosol Can

|

Chemical Composition(%) |

Mechanical Property |

|

C:0.04~0.06 |

Yield Strength: (Mpa):280~320 |

|

Si:0.01~0.03 |

TensileStrength: (Mpa):340~390 |

|

Mn:0.18~0.22 |

Elongation:20%~30% |

|

P:0.014~0.016 |

------------- |

|

S:0.006~0.009 |

Application of Tinplate for Aerosol Can

Tinplate is widely used for making all types of containers such as artistic cans, tea cans, painting cans,

chemical package cans and metal printing etc. Its applications are not limited to containers; recently,

tinplate has also been used for making electrical machinery parts and many other products.

Equipment and Facility of Tinplate Steel

Tin Coating Line of Tinplate Steel

Cold Rolling Mill Batch Annealing Furnaces

Cutting Line Stock Area

Quantity Control System of Tinplate Steel

- Q: What is the process of two cold rolling of tinplate?

- Tin plays a major role in preventing corrosion and rusting. It will be the steel strength and formability and corrosion resistance of tin soldering, and beautiful appearance with a material, corrosion resistant, non-toxic, high strength and good ductility properties.

- Q: What are the common misconceptions about tinplate packaging?

- One common misconception about tinplate packaging is that it is easily dented or damaged. In reality, tinplate is quite durable and can withstand rough handling without losing its structural integrity. Another misconception is that tinplate packaging is not environmentally friendly. However, tinplate is highly recyclable and can be reused multiple times, making it a sustainable packaging option.

- Q: How does tinplate packaging contribute to product protection against contamination?

- Tinplate packaging contributes to product protection against contamination by providing a durable and secure barrier between the product and external elements. The tin coating on the steel substrate prevents corrosion and rusting, ensuring the integrity of the packaging. This protects the product from moisture, oxygen, and other contaminants that could compromise its quality or safety. Additionally, tinplate packaging is airtight, preventing the entry of bacteria or microorganisms, further enhancing product protection against contamination.

- Q: What are the latest innovations in tinplate technology?

- Some of the latest innovations in tinplate technology include the development of lightweight tinplate materials, improved corrosion resistance coatings, advanced printing techniques for high-quality packaging designs, and the use of recycled materials in tinplate production to promote sustainability. Additionally, there have been advancements in the manufacturing processes to enhance efficiency and minimize waste.

- Q: Tin and tinSince the back skin as long as tinplate will rust, so why not replace tin?

- Tin and tin, are plated plate, is a low carbon steel sheet, and metal coating. Electroplating and hot plating respectively.The difference between the two plates is that the former tin plated, the latter galvanized, because the two kinds of metals have different chemical properties, so their anti-corrosion ability and use is not the same

- Q: What are the advantages of tin packaging?

- Shapes: tinplate cans can be made into various shapes according to different needs, such as cans, cans, cans, circular elliptical horseshoe and trapezoid etc, can satisfy the different needs of product packaging, and the packaging container more change, promote sales.

- Q: Can tinplate be used for packaging of flammable liquids?

- No, tinplate is not suitable for packaging flammable liquids as it is not resistant to corrosion and may react with the liquid, potentially causing leaks or fire hazards.

- Q: What are the main applications of tinplate in the automotive industry?

- Tinplate is commonly used in the automotive industry for various purposes, including the production of fuel tanks, oil filters, and battery casings. The main applications of tinplate in the automotive sector are primarily due to its properties, such as corrosion resistance, durability, and formability. These qualities make tinplate an ideal material for ensuring the safety and longevity of automotive components.

- Q: Does tinplate corrode over time?

- Yes, tinplate can corrode over time due to exposure to moisture, oxygen, and other corrosive elements. However, the corrosion rate of tinplate is relatively slow compared to other metals, thanks to the protective layer of tin that covers the steel base. Regular maintenance and proper storage conditions can help slow down the corrosion process.

- Q: What are the main challenges in the production of tinplate?

- The main challenges in the production of tinplate include ensuring a consistent quality of tin coating on the steel substrate, controlling the thickness of the tin layer, preventing contamination during the production process, managing the formation of tin oxide, and minimizing the occurrence of defects such as pinholes or scratches on the tinplate surface. Additionally, maintaining a stable and efficient production line, optimizing energy consumption, and complying with environmental regulations are also significant challenges.

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2009 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America;South America; Eastern Europe Southeast Asia; Africa; Mid East Eastern Asia; Western Europe; Central America Northern Europe; Southern Europe; Domestic Market |

| Company Certifications | HACCP;ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 270,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High;Average |

Send your message to us

Tinplate For Aerosol Can-CHBA

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Tons~25 Tons m.t.

- Supply Capability:

- 40000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords