Tinplate with Prime Quality for Easy Open Ends

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tinplate with Prime Quality for Easy Open Ends

Tinplate Specification

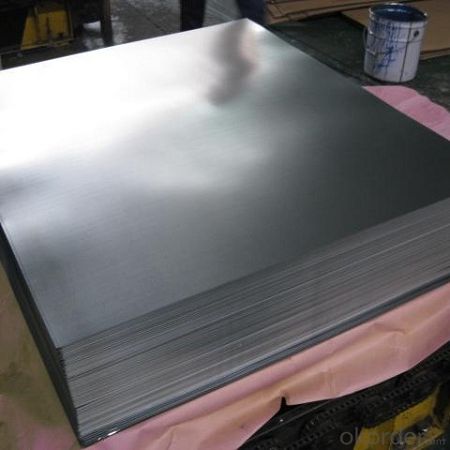

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter. It has extremely beautiful metalllic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

Tinplate Applications

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

Tinplate Pictures

Tinplate Features

Steel Type: MR, SPCC

Temper(BA& CA): T1- T5, DR8- DR10

Coating: 1.1- 8.4g/m^2

Tickness: 0.15- 0.,50mm

Width: 600-1010mm

I.D: 508mm

Coil weight: 3- 10mt

Passivation: 311

Oiling: DOS

Surface finish: Bright, Stone

Quantity for 20 Feet FCL: 20- 25MT

Package: Seaworthy Export Standard Wooden Pallet

Application

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products

Chemicals and painting cans

Dry food ccans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends

Electrical machinery parts

Bakeware and household kitchen parts

Production Standard

GB/T 2520-2000

JIS G3303-2002

DIN EN 10202-2001

ASTM A623M-2002

ISO 11949-1995

- Q: How is tinplate coated with polymer films?

- Tinplate is coated with polymer films through a process called lamination. This involves applying a layer of polymer film onto the surface of the tinplate using heat and pressure. The polymer film adheres to the tinplate, providing a protective barrier against corrosion and enhancing its durability.

- Q: What are the main applications of tinplate in the gardening industry?

- Tinplate is commonly used in the gardening industry for various applications such as plant pots, watering cans, and gardening tools. Its corrosion-resistant properties make it ideal for outdoor use, while its versatility allows for easy customization and branding. Additionally, tinplate offers good strength and durability, ensuring longevity for garden products.

- Q: And what are the main packing materials?

- Maguchi Tetsumi the tank is to sheet metal for tank type packaging materials by crimping, bonded resistance welding processing, by the tank body and the tank bottom and the tank cover is composed of three parts, a tank body packaging container joint, tank body and tank bottom and tank capping.

- Q: How can recycled tin cans be recycled?

- Longhu white tin cans crusher is a company based on years of manufacturing experience carefully developed recovery special grinder, the crusher machine advantages in traditional variety, make full use of impact, shear, impact each other, grinding theory carefully developed.

- Q: Can tinplate packaging be used for industrial products?

- Yes, tinplate packaging can be used for industrial products. Tinplate is a durable and versatile material that provides excellent protection and preservation for various industrial goods. It is commonly used for packaging chemicals, paints, lubricants, and other industrial products due to its resistance to corrosion, moisture, and impact. Additionally, tinplate packaging can be easily customized to meet specific industrial requirements, making it a suitable choice for such applications.

- Q: Can tinplate be used for aerospace applications?

- Yes, tinplate can be used for certain aerospace applications, particularly for non-critical components where weight is not a significant concern. Tinplate is known for its corrosion resistance and affordability, which makes it suitable for certain aerospace applications such as interior fittings, non-structural parts, and packaging. However, for critical components that require high strength-to-weight ratio or extreme durability, other materials like aluminum or titanium are typically preferred.

- Q: What are the different grades of tinplate?

- The different grades of tinplate include Single Reduced (SR), Double Reduced (DR), and Electrolytic Chromium Coated Steel (ECCS).

- Q: How does tinplate packaging contribute to product protection against moisture?

- Tinplate packaging contributes to product protection against moisture due to its inherent properties. The tin coating on the steel substrate acts as a barrier, preventing moisture from seeping into the packaging and reaching the product. This protective layer ensures that the product remains dry and free from any potential damage caused by moisture, such as rust or deterioration. Additionally, tinplate packaging is often sealed tightly, further enhancing its ability to keep moisture out and maintain the product's quality and freshness.

- Q: How does tinplate contribute to the attractiveness of cosmetic packaging?

- Tinplate contributes to the attractiveness of cosmetic packaging due to its unique properties. Its shiny and reflective surface enhances the visual appeal of the packaging, making it look more luxurious and high-end. Additionally, tinplate offers excellent printability, allowing for intricate designs, vibrant colors, and high-quality graphics to be displayed on the packaging, which further enhances its attractiveness. The durability and strength of tinplate also ensure that the packaging remains intact and visually appealing throughout its lifespan.

- Q: What are the main challenges in tinplate recycling?

- The main challenges in tinplate recycling include the separation of tinplate from other materials, as well as the need for specialized recycling facilities and processes. Additionally, the collection and sorting of tinplate waste can be challenging due to its diverse sources and varied forms, such as cans, containers, and packaging.

Send your message to us

Tinplate with Prime Quality for Easy Open Ends

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords