TINPLATE ETP OF Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5; DR8 - DR10;

Annealing: BA & CA

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

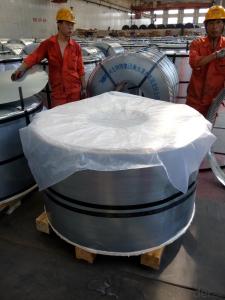

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Application: widely used in every kinds of packing cans,such as tea packaging cans, painting packaging cans, chemical packaging cans and dry food packaging cans; and also mechanical parts

Both Prime and Second Quality Are Available!!!

- Q: How does tinplate compare to stainless steel in terms of properties and applications?

- Tinplate and stainless steel differ significantly in terms of properties and applications. Tinplate, made by coating thin steel sheets with a layer of tin, offers good corrosion resistance and malleability, making it suitable for applications like food and beverage packaging, cans, and aerosol containers. On the other hand, stainless steel, an alloy of steel with chromium and other elements, provides superior corrosion resistance, strength, and heat resistance. It finds extensive use in industries like construction, automotive, kitchenware, and medical equipment. While tinplate is more cost-effective and suitable for lightweight applications, stainless steel offers higher durability and versatility for various demanding applications.

- Q: What are the main innovations in tinplate manufacturing?

- One of the main innovations in tinplate manufacturing is the development of continuous annealing technology. This process allows for a more efficient and precise heat treatment of tinplate, resulting in improved mechanical properties and better coating adhesion. Additionally, the introduction of advanced coating systems, such as chromium-free passivation, has provided a more sustainable and environmentally friendly option for preserving the tinplate's surface and enhancing its corrosion resistance. Moreover, advancements in printing and decorative techniques have enabled manufacturers to create more visually appealing tinplate designs, catering to the evolving demands of consumers.

- Q: How does tinplate perform in terms of oxygen barrier properties?

- Tinplate performs excellently in terms of oxygen barrier properties. The tin coating on the steel substrate acts as an effective barrier, preventing oxygen from permeating through the material. This property makes tinplate ideal for packaging applications, as it helps to preserve the freshness and quality of oxygen-sensitive products.

- Q: How is tinplate used in the production of aerosol valves?

- Tinplate is used in the production of aerosol valves as it provides a protective and corrosion-resistant coating to the valve components. This prevents the valve from rusting or reacting with the contents of the aerosol, ensuring the reliable and safe functioning of the aerosol valve.

- Q: Can tinplate be used for packaging chemicals?

- Yes, tinplate can be used for packaging chemicals. It is a commonly used material for packaging due to its durability, resistance to corrosion, and ability to protect against light and oxygen. Tinplate is also known for its ability to withstand various temperatures and pressures, making it suitable for storing and transporting a wide range of chemicals safely.

- Q: Can tinplate be used for gift packaging?

- Yes, tinplate can be used for gift packaging. It is a versatile material that offers durability and can be easily shaped into various sizes and designs. Tinplate also provides a visually appealing and premium look, making it an excellent choice for gift packaging.

- Q: Can tinplate be used for pharmaceutical packaging?

- Yes, tinplate can be used for pharmaceutical packaging. Tinplate is commonly used for packaging various products, including pharmaceuticals, due to its durability, resistance to corrosion, and ability to provide a protective barrier against light, moisture, and oxygen, which helps maintain the quality and shelf life of pharmaceutical products.

- Q: Can tinplate be used for packaging of non-food products?

- Yes, tinplate can be used for packaging of non-food products. Tinplate is a versatile material that offers excellent durability and corrosion resistance, making it suitable for a wide range of packaging applications including cosmetics, chemicals, and industrial products.

- Q: What are the common printing methods used on tinplate?

- The common printing methods used on tinplate include lithography, offset printing, and screen printing.

- Q: What are the different ways to recycle tinplate closures?

- There are several different ways to recycle tinplate closures. One option is to separate the tinplate closures from other recyclable materials, such as glass or plastic bottles, and send them to a recycling facility where they can be melted down and reused to make new products. Another option is to repurpose tinplate closures for crafts or DIY projects, such as creating decorative magnets or jewelry. Additionally, some communities offer recycling programs specifically for tinplate closures, where they can be collected and reused in various ways.

Send your message to us

TINPLATE ETP OF Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords