Tinplate Sheets for Food Cans Use with Strips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Tinplate Sheets for Food Cans Use with Strips Description

Tinplate Sheets for Food Cans Use with Strips is one of the metal packing materials, which is widely used for making tea cans ,painting cans ,chemical package cans ,food package cans, electrical cable ,battery and metal printing etc.

2. Main Features of the Tinplate Sheets for Food Cans Use with Strips

Steady and high quality

Fast shipment

Good experience for export work

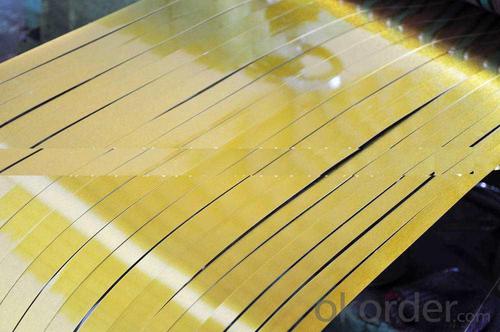

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

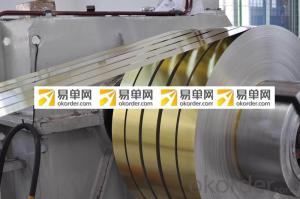

3.Tinplate Sheets for Food Cans Use with Strips Images

4. Tinplate Sheets for Food Cans Use with Strips Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ of Tinplate Sheets for Food Cans Use with Strips

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

- Q: Can tinplate be customized with different designs or logos?

- Yes, tinplate can be customized with different designs or logos. It is a versatile material that can be decorated using various printing techniques such as lithography, offset printing, or embossing. This allows for the creation of unique and personalized designs on tinplate, making it suitable for branding and promotional purposes.

- Q: What are the quality control measures for tinplate production?

- Quality control measures for tinplate production typically involve several steps to ensure the production of high-quality tinplate. These measures may include thorough inspection of raw materials, such as tin-coated steel coils, to ensure they meet the required specifications. During the manufacturing process, regular testing and monitoring of various parameters like coating thickness, adhesion, surface finish, and tinplate dimensions are conducted. Additionally, visual inspections are performed to identify any defects or imperfections. Furthermore, samples are taken at different stages of production for laboratory testing, which may include corrosion resistance, mechanical properties, and chemical composition analysis. These measures help maintain consistent quality and ensure that the tinplate meets the necessary standards for its intended applications.

- Q: How does tinplate packaging contribute to product protection against moisture?

- Tinplate packaging contributes to product protection against moisture due to its inherent properties. The tin coating on the steel substrate acts as a barrier, preventing moisture from seeping into the packaging and reaching the product. This protective layer ensures that the product remains dry and free from any potential damage caused by moisture, such as rust or deterioration. Additionally, tinplate packaging is often sealed tightly, further enhancing its ability to keep moisture out and maintain the product's quality and freshness.

- Q: What are the common surface treatments for tinplate?

- The common surface treatments for tinplate include electrolytic tinplating, chromium plating, and passivation.

- Q: How does tinplate packaging contribute to product reusability?

- Tinplate packaging contributes to product reusability by providing a durable and long-lasting solution. It can be easily cleaned and reused multiple times, reducing the need for single-use packaging. Additionally, tinplate packaging can protect the product from external factors, such as light, moisture, and air, which helps extend its shelf life, further enhancing reusability.

- Q: What are the main technological advancements in tinplate production?

- Some of the main technological advancements in tinplate production include the development of high-speed production lines, automated processes for coating and printing, advancements in tin coating technology for improved corrosion resistance, and the integration of digital systems for quality control and traceability. Additionally, innovations in recycling and sustainability practices have also emerged, enabling more efficient use of resources and reducing environmental impact in tinplate production.

- Q: What do tinplate do?

- If is a tin factory, then electroplating factory, the process is open book, roll up, cold rolled plate by welding, looper, alkali washing, acid pickling, tin plating, soft melting, chemical treatment passivation, oiling and rewinding.

- Q: Can tinplate be used for packaging alcoholic beverages?

- Yes, tinplate can be used for packaging alcoholic beverages. Tinplate is a commonly used material for cans and can provide a protective barrier against external factors such as light and oxygen, ensuring the quality and freshness of the alcoholic beverages.

- Q: What are the transportation considerations for tinplate?

- The transportation considerations for tinplate typically revolve around its weight, fragility, and potential for damage. Tinplate is quite heavy, so proper handling and lifting equipment are necessary to ensure safe transportation. Its fragile nature means that it should be protected from impacts and vibrations during transit to prevent dents, scratches, or other damage. Additionally, as tinplate is susceptible to corrosion, it is important to protect it from moisture and humidity during transportation, such as by using proper packaging and ensuring a dry environment.

- Q: How is tinplate affected by extreme temperatures?

- Tinplate is minimally affected by extreme temperatures due to its high melting point and excellent heat resistance properties. It remains stable and does not undergo significant changes in its physical or chemical properties even in extremely hot or cold conditions.

Send your message to us

Tinplate Sheets for Food Cans Use with Strips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords