ETP TINPLATE of Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5; DR8 - DR10;

Annealing: BA & CA

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

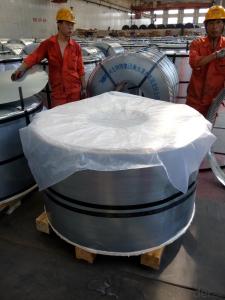

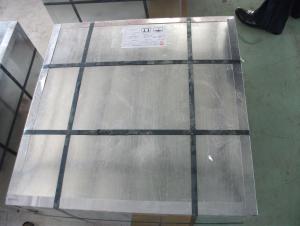

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Application: widely used in every kinds of packing cans,such as tea packaging cans, painting packaging cans, chemical packaging cans and dry food packaging cans; and also mechanical parts

Both Prime and Second Quality Are Available!!!

- Q: How does tinplate perform in terms of lightness and portability?

- Tinplate performs well in terms of lightness and portability. It is a lightweight material that is easy to carry and transport, making it convenient for various applications.

- Q: How does tinplate contribute to the resistance of marine equipment?

- Tinplate contributes to the resistance of marine equipment by providing a protective coating that helps prevent corrosion and oxidation caused by exposure to saltwater and other harsh marine environments.

- Q: What are the main applications of tinplate in the aerospace industry?

- Tinplate is primarily used in the aerospace industry for manufacturing various components, such as fuel tanks, containers, and protective casings. Its corrosion resistance properties make it ideal for safeguarding against moisture and ensuring the longevity of these critical aerospace components. Additionally, tinplate's lightweight nature contributes to the overall weight reduction of aircraft, enhancing fuel efficiency and performance.

- Q: What are the main trends in tinplate packaging?

- The main trends in tinplate packaging include a shift towards eco-friendly and sustainable materials, increased customization options for branding purposes, and the integration of technology for improved convenience and functionality.

- Q: Can tinplate be used for non-packaging applications?

- Yes, tinplate can be used for non-packaging applications. Tinplate's corrosion resistance, durability, and versatility make it suitable for various non-packaging uses such as construction materials, automotive parts, electrical equipment, and decorative items.

- Q: How does tinplate perform in terms of resistance to UV radiation?

- Tinplate generally provides good resistance to UV radiation due to its metallic coating, which acts as a protective barrier against the damaging effects of the sun's rays. However, prolonged exposure to intense UV radiation can still cause some degree of degradation over time.

- Q: What are the different types of tinplate coatings available?

- There are several types of tinplate coatings available, including electrolytic tinplate (ETP), tin-free steel (TFS), and lacquered tinplate. ETP is the most common type and it provides excellent corrosion resistance and a shiny appearance. TFS, on the other hand, does not contain tin and is coated with a layer of chromium or chromium oxide, offering similar corrosion resistance as ETP. Lacquered tinplate is coated with a layer of lacquer, providing additional protection against corrosion and enhancing the appearance of the tinplate.

- Q: Does the tinplate have a tensile rate? Thank you heroes!

- Where Sn is the tin plating, tin tin iron is also called the iron horse known as tin plating English, abbreviated as SPTE, is a commercial pure tin plating of cold rolled low carbon steel sheet or strip. Tin plays a major role in preventing corrosion and rusting. It will be the steel strength and formability and corrosion resistance of tin soldering, and beautiful appearance with a material, corrosion resistant, non-toxic, high strength and good ductility properties.

- Q: What are the main factors influencing the supply of tinplate?

- The main factors influencing the supply of tinplate are the availability and cost of raw materials such as tin, steel, and other alloys, the production capacity and efficiency of tinplate manufacturers, government regulations and policies, fluctuations in demand from industries such as packaging, automotive, and electronics, and global economic conditions and trade dynamics.

- Q: What are the common labeling options for tinplate containers?

- The common labeling options for tinplate containers include adhesive labels, heat transfer labels, direct printing, and embossing.

Send your message to us

ETP TINPLATE of Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords