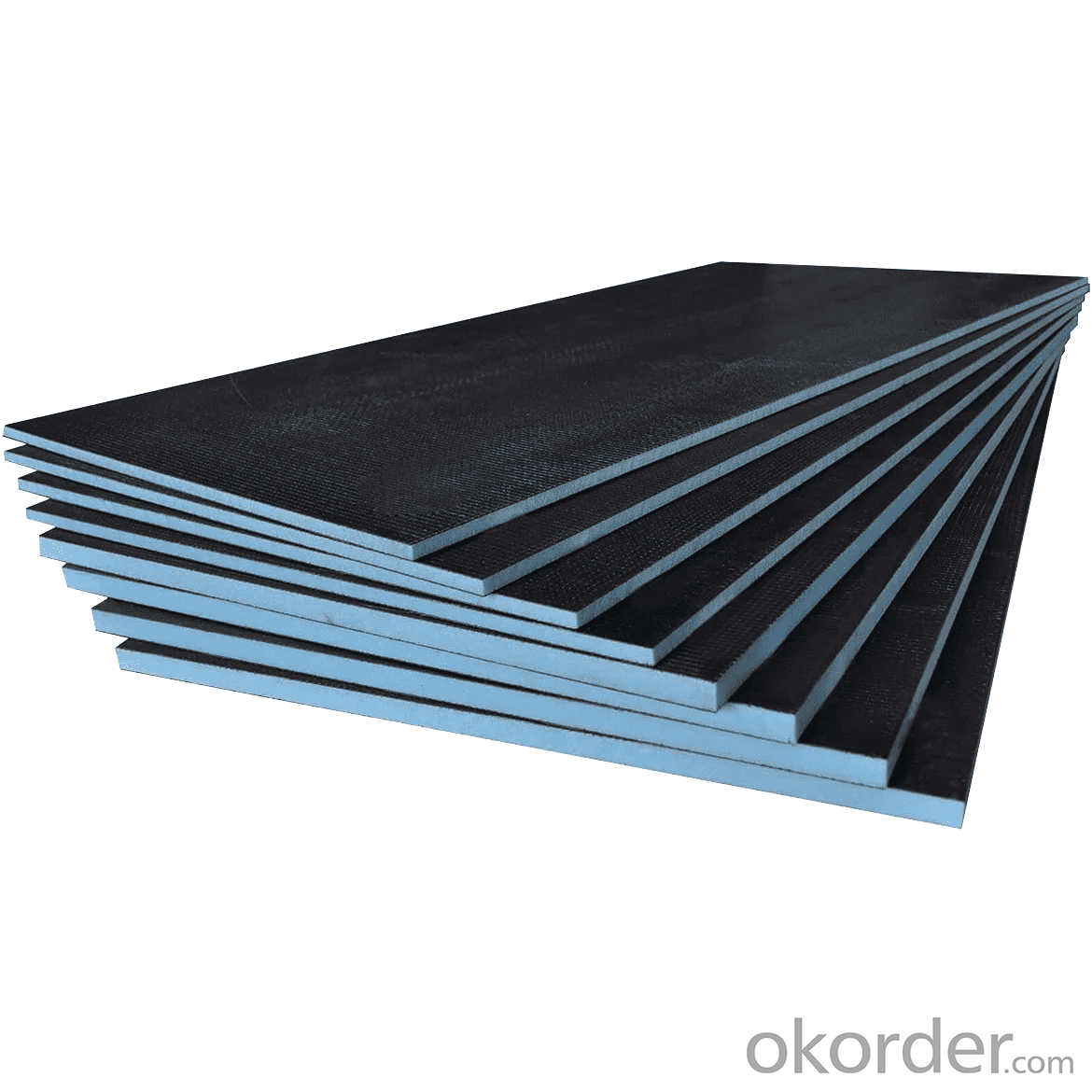

Thermal Insulation Board for Walls Floors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

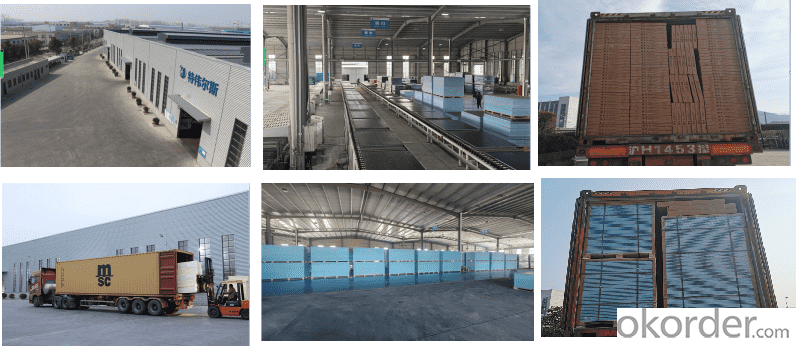

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wetroom 12mm xps Tile Backer Board For Walls and Floors 1200mm x 600mm (5 Pack)

When it comes to effective insulation solutions for your construction or tiling projects, XPS insulation boards are a reliable choice. We offer a wide range of XPS insulation boards, also known as XPS foam boards or simply XPS boards. These boards are designed to provide excellent thermal insulation, moisture resistance, and durability, making them ideal for various applications.

XPS insulation boards are constructed from extruded polystyrene foam, known for its high compressive strength and low thermal conductivity. This combination of properties makes XPS boards highly efficient in reducing heat transfer and improving energy efficiency in buildings. Whether you're insulating walls, floors, or roofs, XPS insulation boards offer a reliable solution.

Our selection of XPS foam boards includes various thicknesses and sizes to accommodate different project requirements. From smaller DIY projects to large-scale commercial installations, we have the right XPS insulation board to suit your needs. These boards are easy to handle and cut, allowing for precise fitting and installation.

we pride ourselves on providing high-quality products and exceptional customer service. Our knowledgeable staff are available to assist you in selecting the right XPS insulation board for your specific project. We also offer fast shipping and hassle-free returns to ensure your complete satisfaction with your purchase.

Whether you're a professional contractor or a DIY enthusiast, our XPS boards will help you create a comfortable and energy-efficient environment.

Performance parameters

Technical | Assessed to | Rating |

XPS Foam Density | DIN 53420 | 32±0.02kg/m³ |

Compressive strenghth (kPa) | EN 826 | ≥450 |

Thermal conductivity(W/m・K) | EN 12167 | ≤0.030 ≤0.034 |

Dimesional stability % (70±2℃) 48h | GB/T8811-2008 | ≤1.5 |

Flexural Strength (Mpa) | ASTM C203 | ≥2.8 |

Water Absorption(96hrs immersion) | ISO 2896 | ≤1.5 |

Water Vapour Permeability | ASTM E-96 | ≤3.0 |

Flammability | EN13501 | B2 |

Tensile strength perpendicular to the board | GB/T30595-2024 | ≥0.2Mpa |

Advantages

Advantages

1. impact resistant and rigid.

2. Waterproof and temperature resistant & Vapour retardant.

3. Thermally insulating.

4. Quick and easy to install.

5. Lightweight, easy to handle and transport.

6. Easy to cut (with a utility knife).

7. Applied to use on any kind of background substrate.

8. Applied to freestanding p

artition walls,shelves, coverings and similar surfaces.

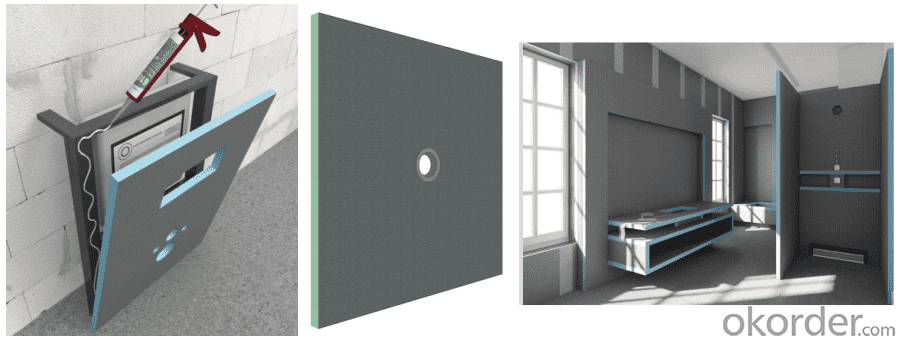

Applications

Bathrooms and Showers: Perfect for walls and floors in showers and bathrooms where water exposure is constant.

Kitchens: Ideal for kitchen backsplashes and countertops, providing a moisture-resistant base.

Wet Rooms: Suitable for creating fully waterproof wet rooms with tiled surfaces.

Exterior Spaces: Can be used in outdoor areas where moisture and temperature changes are a concern.

- Q: Slope roof drains do not need to be waterproof

- The overall rigid waterproof layer is often due to these small structural nodes handled properly, resulting in the failure of the entire roof waterproof.

- Q: What is the price of a waterproof window cover?

- 3, decorative panels Decorative panels are divided into paint-free panels and paint panels. Currently on the market, there are many window-free products, paint-free board is 5 mm density, the board pressure a layer of thin layer of color paper, due to the type of color paper, so there can be a lot of paint-free Color. Paint decorative panel is the surface of a layer of veneer plywood, there are many types, different wood has different colors. The benefits of window sets

- Q: How do you make waterproofing in the kitchen and bathroom?

- Kitchen and toilet to do waterproof, it is recommended to use kitchen and toilet waterproof paste, it is specifically for the kitchen and toilet water and easy to seepage yin and yang angle, pipe, sanitary ware, floor drain and other parts of the development, special materials, so waterproof Ordinary waterproof material is better, and waterproof coating construction is more convenient, only need to brush 2-3 times, the thickness of 1.2-1.5MM on it. Specific construction methods are as follows: 1, will penetrate the root, floor drain and other cracks, need to repair the site cut into "V" shape, and clean, sprinkler moist; 2, the [infiltration of crystalline repair mortar] add water (water and ash weight ratio of 1: 2 ~ 3) mixed evenly, in the early condensate before (5 minutes) to repair the construction, the root of the pipe, the floor drain, yin and yang, Should be made r angle; 3, repair mortar after the final setting, the [durable waterproof paste] powder and liquid material mixing evenly, put it aside for 3 minutes, and then stir evenly after brushing on the base surface, should be cross brush twice, and so on The first time after the dry, can be carried out the second time construction; 4, after the completion of anti-stamped, 48 hours after the closed water test.

- Q: Can Henkel have water against him?

- Can ah ~ watered effect on the discount friends are high with the general are good, powder + pulp! Do not need to add water

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- SBS Styrene-based thermoplastic elastomer is the largest yield (more than 70%) of SBCs, the lowest cost and wider application. It is a triblock copolymer with styrene and butadiene as monomer. Plastic and rubber properties, known as the "third generation of synthetic rubber".

- Q: Nanning building waterproof material market where

- to buy what materials are going to go to some factories, such as paper, printing materials and other manufacturers in the Nanning High-tech Zone or Nanning Economic Development Zone may be more

- Q: Js waterproof coating without powder can brushing

- 3. Construction: brush with a brush or brush directly to the JS waterproof coating on the base surface, the intensity of the use of uniform, can not leak; if used for moisture, just brush a layer; for waterproof, To three layers. When the first layer of JS waterproof coating dry to just sticky hands (usually 1-2 hours), you can brush the second layer, every two layers of brushing direction should be straight to the intersection;

- Q: There is no formaldehyde in the finished putty

- The current status of the market to buy regular manufacturers out of semi-finished products putty and formaldehyde has nothing to do, because the status quo countries also hit the product containing formaldehyde in the building materials, the current market traffic is relatively large for the water putty, putty powder which is natural mineral powder And water-based glue synthesis, because the product life long-term pollution-free, so that is impossible to contain formaldehyde, but engineering putty is usually on-site modulation, and in order to increase the adhesion of putty powder inside the addition of a large number of construction glue (Containing formaldehyde).

- Q: Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- Second, the completion of the construction of the membrane and the acceptance of qualified, should do the protection of finished products, it is recommended to use cement mortar to do protective layer, construction should pay attention to the surface should be smooth pressure, and set the surface sub-grid, 1 m2. If the use of block material to do the protective layer, the sub-grid area should not be greater than 100 square meters, sub-grid width should not be less than 20mm; if the use of fine stone concrete protective layer, the sub-grid area should not be greater than 36 square meters. Note: Regardless of which protective layer is used, a separation layer should be provided between the waterproofing layer and the protective layer.

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 4: sauna board ????This is a dedicated wood panel for the sauna, but it can also be used in the kitchen and bathroom, generally degreased, with high temperature, not easy to deformation, health and environmental protection and other characteristics, even if there is a long time in the water Will not rot, usually painted in a layer of paint decoration, can make the overall ceiling more beautiful.

Send your message to us

Thermal Insulation Board for Walls Floors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products