The Sandwich board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Packed in carton, then wrapped with LLDPE stretch film. Package Size: 30~33pcs/package, 2 packages/pallet. Or packed in your needs. |

| Delivery Detail: | delivery 5 working days after received your payment |

Specifications

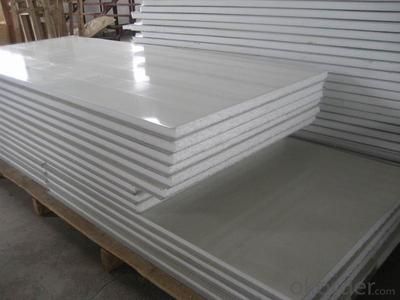

sandwich board

1 Smooth surface

2 light weight

3 high strength

4 environment friendly

PP honeycomb panel (plastic sandwich panel)(building material)

Specifications :

PP6 (Cellcore diameter is 6mm)*

PP8 (Cellcore diameter is 8mm)*

PP10 (Cellcore diameter is 10mm)*

PP12 (Cellcore diameter is 12mm)*

PP honeycomb panel can be supplied with both sides laminated with non-woven polyester tissue in either 40g/ m² or 60g/m², then clients can combine honeycomb with different panels easily .

pp honeycomb core is an excellent material for sandwich construction.

Its polyester non-woven surface is easy to be bonded and fit for most kinds of surface sheet.

Packaging & Delivery

| Packaging Detail: | Packed in carton, then wrapped with LLDPE stretch film. Package Size: 30~33pcs/package, 2 packages/pallet. Or packed in your needs. |

| Delivery Detail: | delivery 5 working days after received your payment |

Specifications

sandwich board

1 Smooth surface

2 light weight

3 high strength

4 environment friendly

PP honeycombpanel (plastic sandwich panel)(building material)

Specifications :

PP6 (Cellcore diameter is 6mm)*

PP8 (Cellcore diameter is 8mm)*

PP10 (Cellcore diameter is 10mm)*

PP12 (Cellcore diameter is 12mm)*

panel can be supplied with both sides laminated with non-woven polyester tissue in either 40g/ m² or 60g/m², then clients can combine honeycomb with different panels easily .

Its polyester non-woven surface is easy to be bonded and fit for most kinds of surface sheet.

- Q: Use the sandwich board to do the quotation of the wall how to do ah

- The board of the board is made of lightweight Polish special cement, EPS granule, expanded perlite, a variety of high-molecular light aggregate for core board, strong composite treatment made of lightweight partition plate

- Q: Rock wool color steel sandwich panels how to choose

- Selection: Caigang rock wool sandwich board sub-machine board and manual plate two, Caigang sandwich panel is made of two layers of color coated steel plate for the surface layer, through the automatic compound molding machine, in the steel plate coated glue , At the same time on both sides of the board embedded in thin-walled channel, the pressure, blanking from the plate. 1, the mechanism of rock wool color steel sandwich panel specifications: L × 1150 × 50, L × 1150 × 75, L × 1150 × 100 2, handmade rock wool color steel sandwich panel specifications: L × 985 × 50 3, color steel rock wool sandwich panel thickness is divided into: 50mm, 75mm, 100mm, 150mm. 4, rock wool density: ≥ 120kg / m3 5, thermal conductivity: ≤ 0.046w / m.k 6, combustion performance: A-level (non-combustible) Caigang rock wool sandwich board for drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling, partition and so on. Fire time is 70 minutes. Thickness 50-150mm rock wool insulation board is basalt and other natural ore as the main raw material, rock wool insulation board by high temperature melt fiber, adding appropriate amount of binder, curing and made of processing. Rock wool insulation board products for industrial equipment, construction, insulation, noise and so on.

- Q: Build a color steel sandwich panel production plant how much money

- The general machine price of 25 million or so, the venue costs plus how much raw materials you need, you can run the general about 100 million, but the funds to return to the fast, can not have too much debt.

- Q: Flour mill production workshop, steel frame, roof with glass wool cotton sandwich panel (veneer) whether it can,

- I can answer; I can not use color steel to answer;

- Q: Polyurethane sandwich panel system of fire resistance, the general can be how much you like 100 thick

- Internal use of B1 grade polyurethane foam core material, fire resistance and panel material. For example, both sides of the use of cement-type plate and other composite, you can achieve composite A-class. While the use of color composite plate on both sides of the sandwich panel can not achieve composite A-class.

- Q: EPS sandwich panels, PU sandwich panels and rock wool sandwich panels of the sound effects which is good?

- Fireproof rock wool> Glass wool> PU> EPS Insulation EPS> PU> Yanmian> Glass wool Sound insulation with almost the same Price PU> glass wool cotton = rock wool> eps So much about it

- Q: Sandwich panel wall design please help?

- Is this 127 square? 5.45 and 3.85 are two sides of the width of the original is a large, now divided into two large one small, long is 15 meters, in front of the board height is 3.27 meters. Followed by 2.87 on both sides of the wide plate height is 3.2 meters. So calculated out of 127 square feet

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q: Sandwich panel sandwich board classification

- According to the functional requirements of Party A or plant to choose the type of roof sandwich panels, such as you want to set fire, then generally use rock wool; insulation, then with the composite board, as is the general insulation or important insulation (for cold storage) According to his weight. As for the upper and lower board general Party has a request, if the party did not ask, it is like a routine

- Q: Polyurethane insulation board and polyurethane color steel sandwich panels What is the difference

- Hello, please understand the difference between the two. Polyurethane insulation board is commonly used in the north of a kind of insulation materials, attached to the external walls, roof, shelter, etc.. The main role is to heat, secondary can be waterproof, flame retardant. Polyurethane color steel sandwich panels, refers to the ordinary polyurethane insulation board outside the single or double metal composite panel (ordinary color steel) as the surface, the middle folder of the polyurethane insulation board, such material surface strength is greater, remove Brush the process of paint. Used for the roof of the plant structure, or slope roof.

Send your message to us

The Sandwich board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords