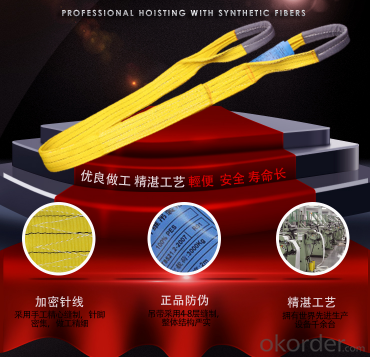

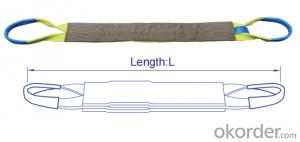

Textile Sling TYPE W01 (EYE TYPE) Textile Sling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Textile sling factory is the largest base for lifting belts in the world with the production capacity over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc.

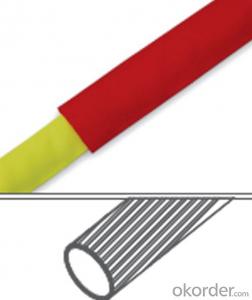

The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope and traction rope, according to different using environments, different materials would be used, such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene material). We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

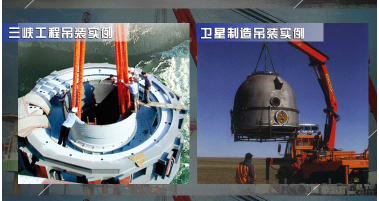

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, aerospace and other fields.

Achievements in scientific research:

In 1997, we drafted out the industrial standard for textile slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic progress for the Chinese textile sling industry.

In 2007, we revised JB/T8521.1-2007 “Textile Sling – Safety - Part 1: Common use webbing sling” and JB/T 8521.2-2007 “Textile Sling - Safety - Part 2: Common use round sling”.

In 2009, we edited GB/T 23914.2-2009 “Road vehicle mounted fixtures – Safety – part 2: Synthetic ratchet strap assemblies”, participated in writing TB/T 3123.11-2009 “Rescue devices for railway accidents - part 11: high-performance textile sling”.

In 2014, we participated in writing GB/T 30667-2014 “Polyester and polyolefin dual Fiber rope” and GB/T 30668-2014 “8 strands, 12 strands and multiflament braided Ultra high molecular weight polyethylene fiber rope”.

- Q: What tools are slings in lifting operations? What is the function of the slings?

- Sling is one of the most common operation tools in hoisting operation.

- Q: What are the dangerous sections of the crane hook?

- ) C -C section of the section is the thinnest part of the hook column in a sling tension, have pulled off the trend. Here the maximum tensile stress, it is also dangerous section.

- Q: 20 tons sling rope, steel wire or chain?

- The main - phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope and coated steel wire rope wire rope varieties, for reference only

- Q: Which brand is better for imported rigging?

- Germany's mechanical products are better, quality world-class, CarlStahl sling rigging is Germany's old brand.

- Q: What does the inspection of rigging involve?

- The stainless steel wire rope is mainly made of 304 or 316 stainless steel. The anti-corrosion effect is excellent, but the price is expensive4. carbon coated steel wire rope, wire rope based on polyethylene, polypropylene or nylon outer coating5. smooth wire rope, short service life, the market demand is declining, the phosphating coating steel wire rope round out.

- Q: What are the specifications for the length, length, and method of operation of the wire rope?

- The fatigue life is three times the same structure of plain steel wire rope, the highest value of contrast test has reached an alarming four times, can be verified by fatigue test, fatigue life ability if they have on their own to do comparative experiments, this test results the most credible, the service life of wire rope and the fatigue life is proportional to a long fatigue life use the same proportion of life extension, the use of lower cost, better stability.

- Q: Is the sling the same thing as the rigging?

- This is not strictly divided, if not to say that the rigging refers to those parts of the spreader is rigging, such as rings, ring buckle, hook, shackle. The sling is a wire rope, lifting chain, lifting belt, these rigging consisting of a complete set for lifting tools, that is, sling. In practice, the two are inseparable. So they are generally called rigging companies. Hope to help you, which is the media, and have the opportunity, please welcome to interview our company.

- Q: What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 4. coated steel wire rope, the carbon steel wire rope based on the rope or rope coated with polyethylene or polypropylene5. smooth wire rope, in 1834 the British began production in China in 1939 started production in Tianjin No.1 steel wire rope factory, with the phosphating coating steel wire rope into the market size gradually increased, will be fully replace phosphating coating steel wire rope.

- Q: How to choose the right sling?

- The selection of rigging should be adapted to the kind of articles, environmental conditions and specific requirements.The sling to carry out strict inspection, in accordance with safety color to use, if found damaged sling can not be reused, need for scrap processing.The slings used for lifting operations must be of the same length.The sling shall not exceed its rated lifting capacity, and the sling shall not exceed its maximum safe working load.

- Q: Which sling manufacturer is more reliable?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

Send your message to us

Textile Sling TYPE W01 (EYE TYPE) Textile Sling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords