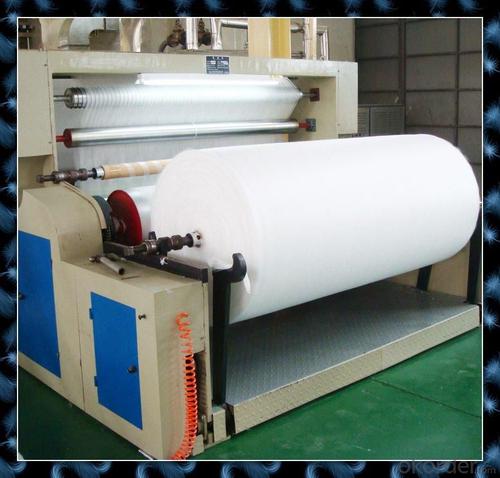

Textile Raw Materials Processing Machinery E

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of Textile Raw Materials Processing Machinery E

| Packaging Detail: | to be packed in seaworthy strong wooden case or carton. |

| Delivery Detail: | about 20days after receipt of the down payment. |

Specifications of Textile Raw Materials Processing Machinery E

It is used for making hollow cotton fiber PP into the fluffy cotton products.Textile Raw Materials Processing Machinery.

Main specification:

output: 100~350kg/h

Power:

Total power; 2.95KW voltage: 380V, 50Hz

Main power : 2.2kWthe power of the conveying fan: 0.75kW

overall size :( L*W*H): 3000×850×1300mm

gross weight: 600kg

Application of Textile Raw Materials Processing Machinery E

It is mainly used for making hollow cotton fiber PP into the fluffy cotton products look like clouds

And applicable to garment, bedding, pillow, and stuff toy, Make products more plumpy & elastic.

It wears conveying fan (user can choose the outlet, it can be padded directly).

- Q: What is the rapier?

- The positive weft insertion method has a strong variety of adaptability, can adapt to all kinds of yarn weft insertion

- Q: What is the principle of air-jet looms?

- Easy to operate and safe operation, with a wide variety of adaptability, less material consumption, high efficiency, high speed, low noise, has become the most promising new one of the cloth

- Q: Why rapier loom electric control box 100v light does not shine?

- With shuttleless looms instead of shuttle looms, rapier looms will become the main production of woven fabrics.

- Q: What is steaming technology?

- Through the steaming to make wool fabric shape stable, feel, gloss to improve the process

- Q: What is weight gain technology?

- Repeated handling, by weight up to 100%. But after weight gain finishing silk fabric strength, elongation and wear fastness have declined, and unfavorable storage, more vulnerable to sun exposure after fragile

- Q: What is the reason why the rapier weft?

- Two weft broken in the weave outside the sword was not taken away, the weft is too loose, the election pole is too high, the side cover is too high, it will lead to weft into the jaws but not into the gripper inside (can be observed to send Sword, sword shell on the traces of weft marks.) Sword head was hit deformation will have this possibility (side support over short, weft just pressed into the bad parts, weft yarn did not enter the gripper, There are some send sword sword was hit with the knife-like, of course, such a broken weft are often accompanied by broken by)

- Q: What is the characteristic of the shuttleless loom?

- The Therefore, the use of shuttleless looms for the increase in fabric varieties, adjust the fabric structure, reduce fabric defects, improve fabric quality, reduce noise, improve the working conditions of great significance

- Q: What is Uquid's finishing?

- Which can reduce the shrinkage of the fabric, increase resilience, breaking strength and hygroscopicity, feel flexible, good elasticity, strong wrinkle resistance, stable size

- Q: How high is the efficiency of towel rapier looms?

- All the jet on the basic varieties can be on the rapier, but for jacquard, multi-color weft (greater than four-color) on the jet requirements on the high, jet has sixteen jacquard, a dual-axis configuration, there are six- The price is not a grade. Jet cloth on the cloth is very smooth and smooth, basically no overhaul.

- Q: What is the difference between air-jet looms and water-jet looms for weft storage?

- Spray the different carrier, water is water, jet is used high pressure gas.

1. Manufacturer Overview

| Location | Chuji, China |

| Year Established | 2008 |

| Annual Output Value | 100Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 12000 square meters |

| No. of Production Lines | Above5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Textile Raw Materials Processing Machinery E

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords