Textile Raw Materials Processing Machinery A

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of Textile Raw Materials Processing Machinery A

| Packaging Detail: | to be packed in seaworthy strong wooden case or carton. |

| Delivery Detail: | about 20days after receipt of the down payment. |

Specifications of Textile Raw Materials Processing Machinery A

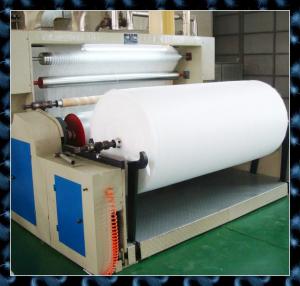

It is used for making hollow cotton fiber PP into the fluffy cotton products.Textile Raw Materials Processing Machinery.

output: 100~350kg/h

Power:

Total power; 2.95KW voltage: 380V, 50Hz

Main power : 2.2kWthe power of the conveying fan: 0.75kW

overall size :( L*W*H): 3000×850×1300mm

gross weight: 600kg

Application of Textile Raw Materials Processing Machinery A

It is mainly used for making hollow cotton fiber PP into the fluffy cotton products look like clouds

And applicable to garment, bedding, pillow, and stuff toy, Make products more plumpy & elastic.

It wears conveying fan (user can choose the outlet, it can be padded directly).

- Q: what is pressing technology?

- Pressure finishing is in the hot and humid conditions under the mechanical pressure to make the fabric smooth, improve the gloss, improve the feel of the process, similar to other fabric calendering finishing

- Q: What are the classification of shuttleless looms?

- Air jet loom: with the jet of compressed air to the weft yarn traction, the weft with the shed. The biggest feature of air-jet looms is fast speed, high labor productivity, suitable for plain and pattern fabric, fine special high-density fabric and large fabric production.

- Q: What is the weft insertion of the rapier loom?

- The weft is inserted from the weft picking weft and the weft of the weft picking weft is introduced into the shed, and in the middle of the shed, the weft picks take the weft of the weft sword, Weft pull out the shed, complete weft insertion.

- Q: What is the reason why the rapier weft?

- Weft rope fall in the sword side, the common is the folder behind the spring bar loose loose, folder yarn and hook head wear, release plate wear, the release does not simply lead to the hook inside the extra weft, in the second weft There will be a situation is to change with the sword with the situation there is such a situation, that is, we do not install the sword protection board, the arrow in the starting track which beating, weft will slip, the best way is Polished sword on both sides of the protection board, the basic problem can be solved.

- Q: What is weight loss technology?

- Polyester staple fiber and its blended yarn and weft silk woven fabric after finishing, Ping Ting smooth, but also get a similar effect.

- Q: What is velvet?

- Shaving can improve the fabric feel and appearance, increase its warmth and feel and so on.

- Q: What is shearing?

- General wool fabric, velvet, artificial fur and other products, are subject to the shearing process, but their requirements are different.

- Q: What is the structure and principle of the rapier loom?

- The start of the loom, the brake, the weft, the electronic weft, the electronic letters, and the electronic winder are controlled by the microprocessor.

- Q: What are the causes of the formation of the shaft weaving machine?

- Right swords head release time is too early, or the right sword head out of the shed too early, this time the shed has not yet closed, weft in the shed shrinkage, the formation of weft.

- Q: What is soft technology?

- The effects of different softeners on the fibers and the resulting softness and other effects are different

1. Manufacturer Overview

| Location | Chuji, China |

| Year Established | 2008 |

| Annual Output Value | 100Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 12000 square meters |

| No. of Production Lines | Above5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Textile Raw Materials Processing Machinery A

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords