Textile Dyeing Machinery E

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

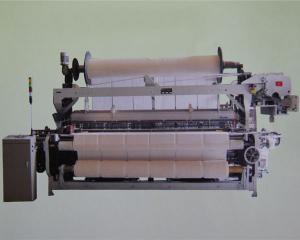

Application of Textile Dyeing Machinery This model is suitable for bleaching and dyeing various natural fabrics weighting from 50g/m2 to 100g/m2 under normal temperature and normal pressure. It is also applicable for a wide range of blended fabrics like rayon, acrylic, terylene, etc. This model adopts a new circulatory system of dye liquor and a special dual nozzle design, combining the latest dyeing techniques. With an extremely low liquor ratio as 1:5, the machine is able to maintain the fabulous dyeing quality. It saves water, dyestuff, steam and chemical addictives, shortens process cycle time, thus dramatically reduces production cost and improves efficiency. Meanwhile, this model is more environment-friendly because less effluent needs to be treated. Technical data of Textile Dyeing Machinery Liquor ratio: 1:5 Max. Fabric speed: 350m/min Max. Capacity: 250kg/tube Max. Working temperature: 980C Heating rate: Average 50C/min (saturated vapor pressure at 0.7MPA) Cooling rate: 980C -850C,Average20C/min(cooling water at 250C 0.3MPA) Packaging & Delivery of Textile Dyeing Machinery Packaging Detail: wooden package Delivery Detail: 1-2 months

- Q: What is the transformation of the textile industry?

- Second, the new enterprise projects to upgrade the technical equipment as the focus, to achieve leapfrog development. The level of equipment is the basic condition of the competitiveness of the textile industry, so the cotton textile enterprises should put limited funds into the use of advanced cotton textile technology, to support the use of new and efficient cotton textile technology equipment, automatic doffer sliver Spinning technology and coarse, fine network of machines.

- Q: What are the hazards of textile warehouses?

- First, the stereotypes to heat the oil and electric heating as a heat source, thermal oil leakage and electrical heating temperature control devices are prone to fire. Second, the fabric by the stereotypes of the oven to produce organic oil (from the next process), and the fabric surface of the fly, fiber particles mixed to form grease, a long time accumulation in the oven easily lead to fire. Third, because some of the fabric, especially chemical fiber, through the mechanical operation of friction generated static electricity, the voltage can be as high as tens of thousands of volts, easy to cause static sparks, causing a fire.

- Q: What is the process of dyeing and dyeing factories?

- Synthetic fibers and man-made fibers, collectively referred to as chemical fiber, referred to as chemical fiber.

- Q: What is luminous printing?

- With the paint printing method, the luminous powder printed on the fabric, the formation of patterns

- Q: What is the difference between the textile industry and the cotton industry?

- Textile industry in China is a labor-intensive and relatively large dependence on foreign industries. China is the world's largest textile and garment production and exporting countries, textile and garment exports sustained and stable growth to ensure that China's foreign exchange reserves, balance of payments, the RMB exchange rate stability, to solve social employment and the sustainable development of the textile industry is essential.

- Q: What is the distribution of China's textile industry in developed areas?

- Textile industry is the fastest growing in China, the most influential international industry. After the reform and opening up, the increasingly strong national strength, open economic policy, hard-working people, so that China quickly became the world's largest producer and exporter

- Q: How is China's textile and textile market prospects?

- From a global perspective, the past, textile machinery manufacturing competition is mainly concentrated in Germany, Italy, Switzerland and other textile machinery production power. But in recent years, driven by domestic and Asian market demand, China's textile machinery manufacturing industry continues to expand, China has become the world's largest textile machinery manufacturing country.

- Q: How does the shuttleless loom work?

- The shuttleless locomotive speed is high, usually 4-8 times faster than the shuttle loom, so the large area of the application of shuttleless loom, can greatly improve labor productivity

- Q: What is the difference between the late Qing machine and the British steam textile machine?

- The shortcomings of hydraulic textile: ① limited to the availability of water resources in the rural areas, but also by the climate and the impact of the season.② factory buildings in the river on both sides of the increasingly difficult transportation .3 where the conditions of construction, the landlord took the opportunity to lift High area of the factory area.

- Q: What is the details of the ginning machine in the textile printing and dyeing industry?

- Metal processing industry: steel plate cleaning production line brush roll coating production line brush brush roll straightening brush brush roller combination brush roll. Polishing cleaning industry: all kinds of polishing with bristles brush sanding machine brush brush washing machine brush brush Cotton cloth round cotton cloth wool wool wheel wool round pig mane wheel wire wheel sweeper box brush road cleaning car manganese steel wire brush and cleaning roller brush disc brush brush brush brush. Scrubber disc brush roller brush, brush barrel machine Brush, planter

1. Manufacturer Overview

| Location | Yizheng, China |

| Year Established | 2005 |

| Annual Output Value | 200Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 10000 square meters |

| No. of Production Lines | Above10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Textile Dyeing Machinery E

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords