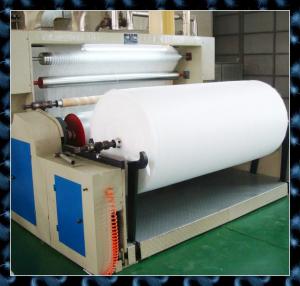

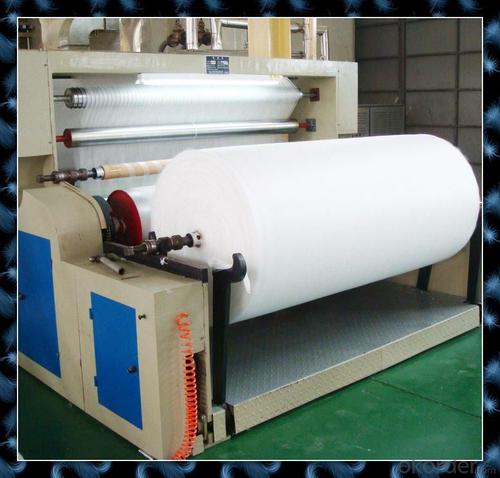

Textile Raw Materials Processing Machinery D

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery ofTextile Raw Materials Processing Machinery D

Packaging Detail: to be packed in seaworthy strong wooden case or carton.

Delivery Detail: about 20days after receipt of the down payment.

Specifications of Textile Raw Materials Processing Machinery D

It is used for making hollow cotton fiber PP into the fluffy cotton products.Textile Raw Materials Processing Machinery.

Main specification:

output: 100~350kg/h

Power:

Total power; 2.95KW voltage: 380V, 50Hz

Main power : 2.2kWthe power of the conveying fan: 0.75kW

overall size :( L*W*H): 3000×850×1300mm

gross weight: 600kg

Application ofTextile Raw Materials Processing Machinery D

It is mainly used for making hollow cotton fiber PP into the fluffy cotton products look like clouds

And applicable to garment, bedding, pillow, and stuff toy, Make products more plumpy & elastic.

It wears conveying fan (user can choose the outlet, it can be padded directly).

- Q: What are the classification of shuttleless looms?

- Water jet looms: the use of water as the weft insertion medium, jet water to the weft to produce friction traction, so that the weft on the fixed cheese into the shed. Water jet looms are characterized by high speed and high unit yield. They are mainly applied to the production of smooth, hydrophobic filament chemical fiber fabrics.

- Q: What is the principle of air-jet looms?

- This weft insertion method can make the loom to achieve high speed and high yield

- Q: Why rapier loom electric control box 100v light does not shine?

- Rapier loom is currently the most widely used shuttleless loom, which in addition to shuttleless loom high-speed, high degree of automation, high-performance production features

- Q: What is easy to soil (soil - releasing)?

- The And because the surface of the fabric with oleophilic, so suspended in the washing liquid dirt is easy to re-stained to the fiber surface, causing re-contamination.

- Q: What kind of looms are used for weaving yarn?

- Mass production can also be made with air-jet looms.

- Q: What is the role of the parchment loom?

- Decisive in the reed that place is generally not light pulp heald frame high arrow arrows with burrs and so on

- Q: How is the loom around the warp?

- Around the warp should be called sizing is wrapped in a large axis on the line

- Q: What is the principle of textile machine?

- In the supply of weft yarn, but also directly using the package package, through the weft access device into the weft insertion mechanism, so that the loom out of the frequent twisting action.

- Q: What is the difference between a textile and a woven fabric?

- Warp knitted fabric is the use of a group or several groups of parallel arrangement of yarn, in the feed to the knitting machine on all the work of the needle at the same time into a circle made.

- Q: What is the difference between the shuttle spinning machine and the rapier textile machine?

- Rapier production than the old car, with the workers less than the old car, reducing the labor force, ease the recruitment difficult

1. Manufacturer Overview

| Location | Chuji, China |

| Year Established | 2008 |

| Annual Output Value | 100Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 12000 square meters |

| No. of Production Lines | Above5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Textile Raw Materials Processing Machinery D

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords