Textile Raw Materials Processing Machinery C

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery ofTextile Raw Materials Processing Machinery C

Packaging Detail: to be packed in seaworthy strong wooden case or carton.

Delivery Detail: about 20days after receipt of the down payment.

SpecificationsIt of Textile Raw Materials Processing Machinery C

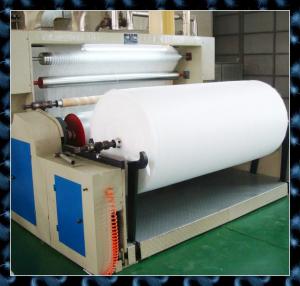

is used for making hollow cotton fiber PP into the fluffy cotton products.Textile Raw Materials Processing Machinery.

Main specification:

output: 100~350kg/h

Power:

Total power; 2.95KW voltage: 380V, 50Hz

Main power : 2.2kWthe power of the conveying fan: 0.75kW

overall size :( L*W*H): 3000×850×1300mm

gross weight: 600kg

Application ofTextile Raw Materials Processing Machinery C

It is mainly used for making hollow cotton fiber PP into the fluffy cotton products look like clouds

And applicable to garment, bedding, pillow, and stuff toy, Make products more plumpy & elastic.

It wears conveying fan (user can choose the outlet, it can be padded directly).

- Q: What is liquid cleaning (Uquid)?

- At the same time to wash through the finishing and deflation finishing laid the foundation

- Q: Why rapier loom electric control box 100v light does not shine?

- Rapier loom electric control box 100v light does not shine may be the fuse burned, it is recommended to replace.

- Q: What is easy to soil (soil - releasing)?

- The And because the surface of the fabric with oleophilic, so suspended in the washing liquid dirt is easy to re-stained to the fiber surface, causing re-contamination.

- Q: How to open a good air jet loom?

- 2. Check the machine and check the edge of the ring is flexible, whether the wear and tear, whether the accumulation of flying, only the pin and the main drum interval is 0.5 mm, whether the trachea leak, focus on oil is oil, tubing Whether there is damage or bending, control box inside the accumulation of flying, to confirm whether the height of the heald frame within 2 mm, the filter exhaust pipe is smooth

- Q: What is the reason why the rapier weft?

- Three weft off the double (send one side of the sword here, that is, the transfer of the transfer of the sword and the weft back to the weft) Weft yarn is too loose lead to the failure of the general we encounter this situation will find the car is not wear Too big, how much arrows, sword belt wear, high arrows. The car wears big will make the transfer too much, we just look at the sword to protect the board to send the sword hit the traces of the transfer is too much

- Q: What is an edge cloth?

- Woven garments because of their style, technology, style and other factors in the processing process and the means of technology are very different.

- Q: What is antistatic (antistaticing)?

- To the process and clothing after wearing the difficulties and trouble

- Q: What are the characteristics of the edge weaving?

- Ribbon woven for a variety of dyeing and finishing methods, in general, printing and jacquard than knitted fabrics, knitted fabrics and felt fabric more fine.

- Q: What is the development of rapier looms?

- The rapier loom is designed to solve the weft insertion method, including rigid, flexible and retractable weft insertion

- Q: Why rapier loom two warp sets of woolen off latitude?

- Back to the sword after the suction from the suction mouth, in the weft scissors under the fall of a lot of two centimeters around the weft, not to be sucked out of the yarn tail to send the sword in the formation of a centimeter around the weft:

1. Manufacturer Overview

| Location | Chuji, China |

| Year Established | 2008 |

| Annual Output Value | 100Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 12000 square meters |

| No. of Production Lines | Above5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Textile Raw Materials Processing Machinery C

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords