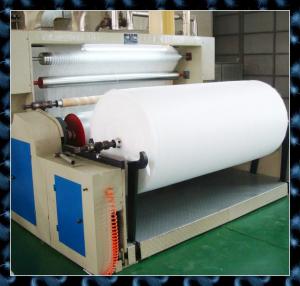

Section Warping Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 100Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Section Warping Machine

1.Width:520mm maximum

2.Diameter: max 190mm

3.Yarn:5-500tex

SU222 hand sample sectional warping machine is the associated equipment,researched and developed by our company for full automatic rapier sample loom.Strong pointshigh efficiency,even warp tension,save materials. Besides,this equipment can be used in the beaming production of brand,ribbon and safety belt.

Packaging & Delivery of Section Warping Machine

Packaging Details: standard seaworth transportation packing

Delivery Detail: 60 days

Technical Parameters of Section Warping Machine

Width:520mm maximum

Diameter: max 190mm

Yarn:5-500tex

- Q: What are the rapier looms used for processing?

- Of course the ordinary rapier produced the fabric without the high speed rapier jet out of the good

- Q: What is the method of elimination?

- Adjust the loom opening time. General rapier loom is 305 degrees, plain weave fabric control in 310 degrees to 315 degrees, twill fabric control in the 320 degrees to 325 degrees is appropriate.

- Q: How much is the razor loom?

- 1, the fabric of the latitude and longitude interweaving more, playing the greater the resistance of the fabric, should use the earlier opening time, when the warp warp crossing angle, the weft angle is also large, so weft displacement, Small, suitable for weaving tight fabric. On the other hand, when the opening is later (less comprehensive), the warp beam warps the weft angle is small, the weft has the retreat, the weft insertion area is increased, and the thin fabric is suitable for weaving.

- Q: What is velvet?

- The velvet of the woven fabric is carried out on a drum-type crimping machine, and the knitted fabric can be carried out in a drum or a washing machine.

- Q: What is the fluff?

- Process, also known as brushed finishing. Mainly used for woolen fabric, acrylic fabric and cotton fabric

- Q: What is the development of rapier looms?

- As early as 150 years ago, a shuttle loom gradually replaced the hand weaving, when the shuttle loom than the handmade fabric production 1 times higher

- Q: What is wrinklng?

- The main methods are: First, the use of mechanical pressure to make the fabric irregular irregular wrinkle appearance, such as hand wrinkling, rope-like wrinkles, stuffing, etc.

- Q: What is the difference between a textile and a woven fabric?

- Knitted fabric is woven by the yarn woven into the fabric, divided into weft and warp.

- Q: What is the difference between the shuttle spinning machine and the rapier textile machine?

- Take the domestic 747 small rapier, 747 good to do eight kinds of colors of the lattice cloth, the old car had to do four kinds. Rapier good to do a single weft, old car shuttle to a back must be double root

- Q: What is the leading maintenance of the rapier loom?

- (0141), after the machine into the hammer into the arm fixed shaft (0141), followed by the back of the hatch arm clamp (0142), to mention the arm, the forefront of the clamp (0142) Arm clip, so that the arm and pull the hook alignment, tighten the tightening screws

1. Manufacturer Overview

| Location | Jiangyin, China |

| Year Established | 1999 |

| Annual Output Value | 10-30Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9002 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 10000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Section Warping Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 100Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches