Textile Dyeing Machinery C

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

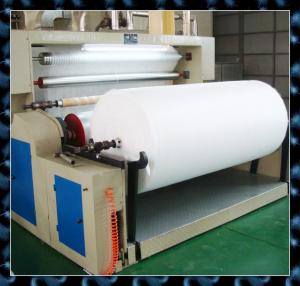

Specification of Textile Dyeing Machinery This model is suitable for bleaching and dyeing various natural fabrics weighting from 50g/m2 to 100g/m2 under normal temperature and normal pressure. It is also applicable for a wide range of blended fabrics like rayon, acrylic, terylene, etc. This model adopts a new circulatory system of dye liquor and a special dual nozzle design, combining the latest dyeing techniques. With an extremely low liquor ratio as 1:5, the machine is able to maintain the fabulous dyeing quality. It saves water, dyestuff, steam and chemical addictives, shortens process cycle time, thus dramatically reduces production cost and improves efficiency. Meanwhile, this model is more environment-friendly because less effluent needs to be treated. Technical data of Textile Dyeing Machinery Liquor ratio: 1:5 Max. Fabric speed: 350m/min Max. Capacity: 250kg/tube Max. Working temperature: 980C Heating rate: Average 50C/min (saturated vapor pressure at 0.7MPA) Cooling rate: 980C -850C,Average20C/min(cooling water at 250C 0.3MPA) Packaging & Delivery of Textile Dyeing Machinery Packaging Detail: wooden package Delivery Detail: 1-2 months

- Q: What is the transformation of the textile industry?

- In China, Nike and Kentucky as a household name, if Taiwan from the technical side of the formation of transformation, the United States from the brand side to find the fulcrum. Through the brand, consumers can get a unique interest and experience, rational experience is based on the product, emotional experience is based on emotion. The same piece of clothing, paste the trademark of Nike, the value of immediately jump up, which is competitive!

- Q: What are the skills of the textile mill?

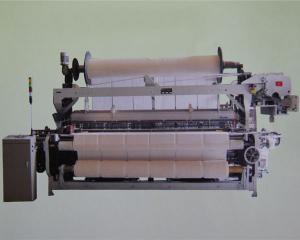

- The shuttle loom holds the weft with a small sheet-like shuttle with a clip and projects the weft insertion. The shuttle loom has the advantages of weft insertion stability, excellent fabric quality and low weft yarn. It is suitable for multi-color weft fabric, fine, thick fabric and wide fabric production.

- Q: What is the process of dyeing and dyeing factories?

- Is the word chemical fiber is gradually moving closer to the synthetic fiber, the people usually referred to as "chemical fiber", the vast majority of cases refer to synthetic fiber

- Q: What is Foam Stereo Printing?

- Foam Stereo printing refers to the addition of a blowing agent plastic resin to the printing slurry

- Q: What is digital printing fabric?

- Digital heat transfer printing, you need to pre-printed on the special paper printing patterns, and then through the transfer of heat transfer to a variety of materials, such as: T-shirts, underwear, sportswear and other clothing.

- Q: What are the common types of textile printing?

- Velvet printing, contrast dark pattern printing, color coating printing (gloss printing)

- Q: What is transfer printing?

- Print the desired pattern with a dye color on paper

- Q: What is the difference between the late Qing machine and the British steam textile machine?

- The shortcomings of hydraulic textile: ① limited to the availability of water resources in the rural areas, but also by the climate and the impact of the season.② factory buildings in the river on both sides of the increasingly difficult transportation .3 where the conditions of construction, the landlord took the opportunity to lift High area of the factory area.

- Q: What is the details of the ginning machine in the textile printing and dyeing industry?

- Mainly used for: pharmaceutical machinery industry: pharmaceutical machinery brush roll. Food processing industry: food washing machine brush roll hair cleaning machine brush roll peeling machine brush roller spiral brush roller coil spring brush roller, brush roller brush brush packaging machine Brushes and all kinds of special-shaped food machinery brush. Glass and ceramic industry

- Q: What is the difference between textile ink and digital printing ink?

- The coating ink is made of nano-pigment, does not plug the nozzle, waterproof, scratch-resistant, high washing fastness, light fastness of 7-8, excluding textiles prohibited color; printing process is short, green, Feel soft, bright colors, ink light fastness excellent.

1. Manufacturer Overview

| Location | Yizheng, China |

| Year Established | 2005 |

| Annual Output Value | 200Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 10000 square meters |

| No. of Production Lines | Above10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Textile Dyeing Machinery C

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords