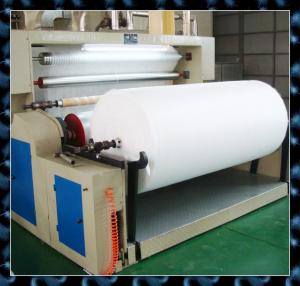

Textile Finishing Machinery C

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Textile Finishing Machinery C

1) It is with speed adjusting motor and LS speed controller which with a large controling range;

2) It is drived by gears,reduced the twitter and noise generated by sprocket;

3) Conveyor belt is of exclusive brand which is with high temperature resistance and anti-static;

4) It is with reasonable design,clothes becomes hard and flat after ironing.

Packaging & Delivery of Textile Finishing Machinery C

Packaging Detail: plywood boxes

Delivery Detail: within 50 days after receiving deposit

Specifications of Textile Finishing Machinery C

1.15 years lifetime 2.CE and ISO9001 3.28 years producing experience 4.all life repairing 5.good after service

- Q: What is the textile fabric according to the organizational structure?

- Knitted fabric, the use of knitting needle yarn or filament into the coil, and then the coil from each other, due to the fabric structure of the coil, the unit length of the amount of stored in the yarn more, so most of the good flexibility.

- Q: What are the characteristics of chemical fiber fabrics?

- C. Nylon Features: elastic and fluffy similar to wool, high strength, conformal, crisp appearance, warm and light, poor hygroscopicity, poor comfort, improved after blending

- Q: What is the garment printing machine?

- Clothing printing machine, belonging to the screen printing category. It can be made into clothing silk screen printing, but also can do pieces of screen printing

- Q: What is the use of memory fabric?

- Memory fabric (Memory Fabric): imports of polyester memory fiber, memory fabric. Memory fiber 75D. The latest international trend of textile fabrics, with its bright appearance

- Q: What is the difference between a dyed fabric and a burnt fabric?

- Printed fabric - woven fabric after printing stains, such as many of the many printed cloth, pattern rich and varied.

- Q: What is the finishing line of textile printing and dyeing?

- Mainly contained in the process: printing: cooked yarn fabric printing, curing, rinsing, ironing finishing;

- Q: What are the common types of garment printing machines?

- A color pattern printed over, the network frame lifted, the belt will be sent to the next frame below the scheduled stop, start the second color pattern of printing and dyeing, and then repeated until a number of colors (more than 10 can be printed Color) printed in turn,

- Q: What are the characteristics of memory silk fabric?

- has a unique memory function, comfortable feel, is any other fiber can not be replaced;

- Q: Long fiber textile finishing, including what?

- Atmospheric pressure suction method: some water-soluble finishing agent in the treatment of wool, silk, cotton and nylon textiles only atmospheric pressure in the treatment of water, similar to water-soluble dye staining;

- Q: How to identify silk and rayon by hand?

- The silk is softer, bright but not glare; the luster of the rayon is similar to metal.

1. Manufacturer Overview

| Location | Yizheng, China |

| Year Established | 2005 |

| Annual Output Value | 200Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 10000 square meters |

| No. of Production Lines | Above10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Textile Finishing Machinery C

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords