Tempered glass 10mm 12mm heat resistant unbreakable

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tempered glass 10mm 12mm heat resistant unbreakable

Advantages of Heat Resistant Glass

The main advantage of Heat Resistant glass is that it helps in insulation by reducing the heat gain and heat loss. Adding multiple layers of glass with gas infill further protects the windows and building from heat loss.

Another advantage of Heat Resistant glass is that it increases the energy efficiency in buildings. The reduced heat transfer lowers the electrical power consumption required for heating or cooling of the space. This drastically cuts down the electrical bills especially in areas subjected to extreme heat or cold. The use of low-e glass and reflective coatings can further improve the efficiency of the windows by further limiting the heat transfer.

Heat Resistant glass also helps in sound insulation and improves the acoustics of the place. The inert gas present in between the two panes of glass does not allow noise to pass through and acts as a barrier between the interiors of the building and the noise that is present outside the building .

The factory mainly produces

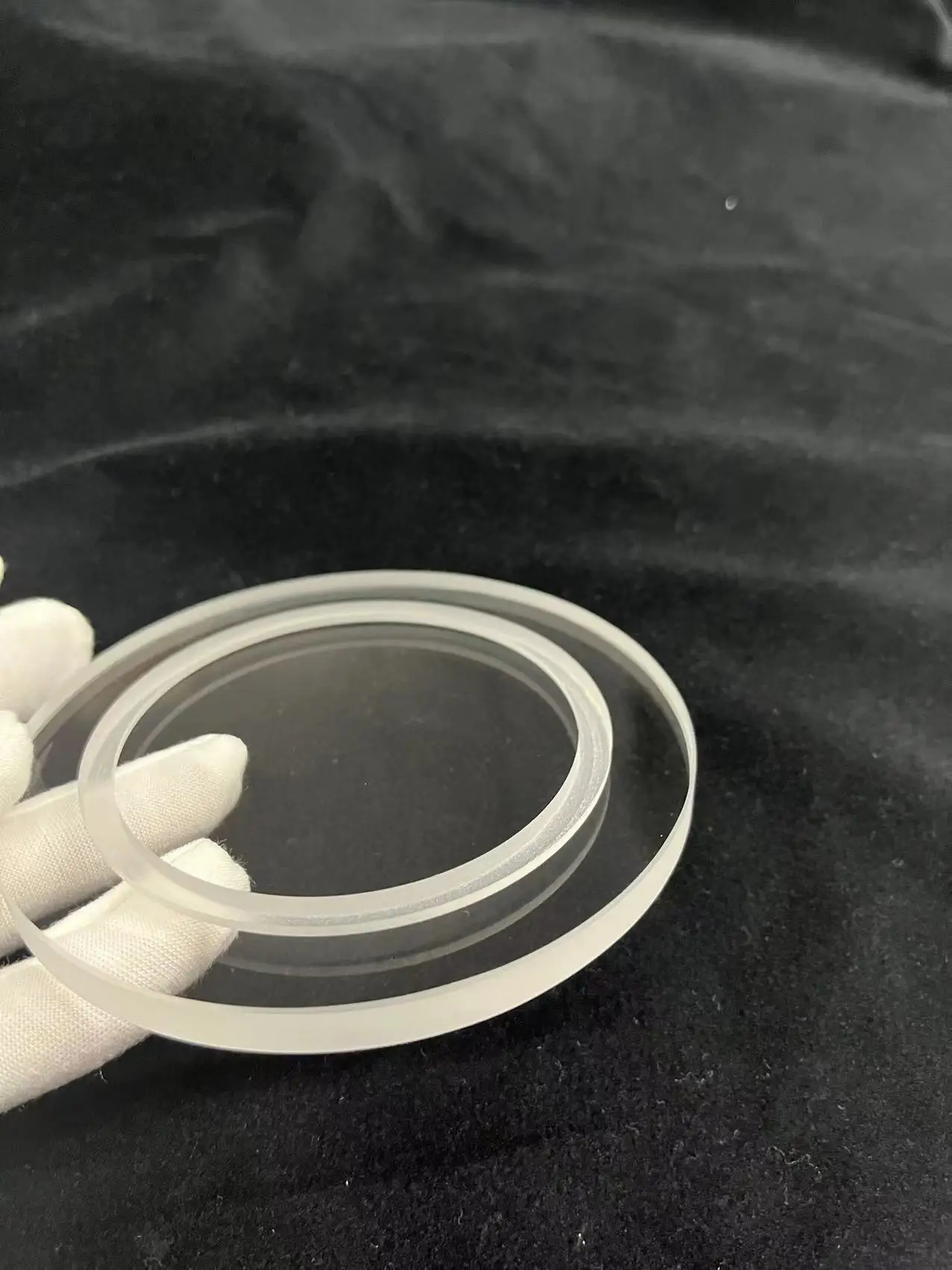

Borosilicate 3.3 heat-resistant glass is widely used in household appliances, electronics, instrumentation, optics, aerospace and other fields.

Borosilicate 3.3 heat-resistant glass has good thermal properties, mechanical properties, optical properties and ultra-high chemical stability. The visible light transmittance is 92%, and the high light transmittance in the near-infrared and ultraviolet bands exceeds 90%. The sign of fluorescence is far lower than that of soda lime glass.

1)Water resistance (International Organization for Standardization 719): Grade A

2)Acid resistance (International Organization for Standardization 195): Grade A

3)Alkali resistance (International Organization for Standardization 695): Grade B

The thickness of the glass ranges from 2.5mm to 15mm, and the maximum size can reach 4800mm×2440mm.

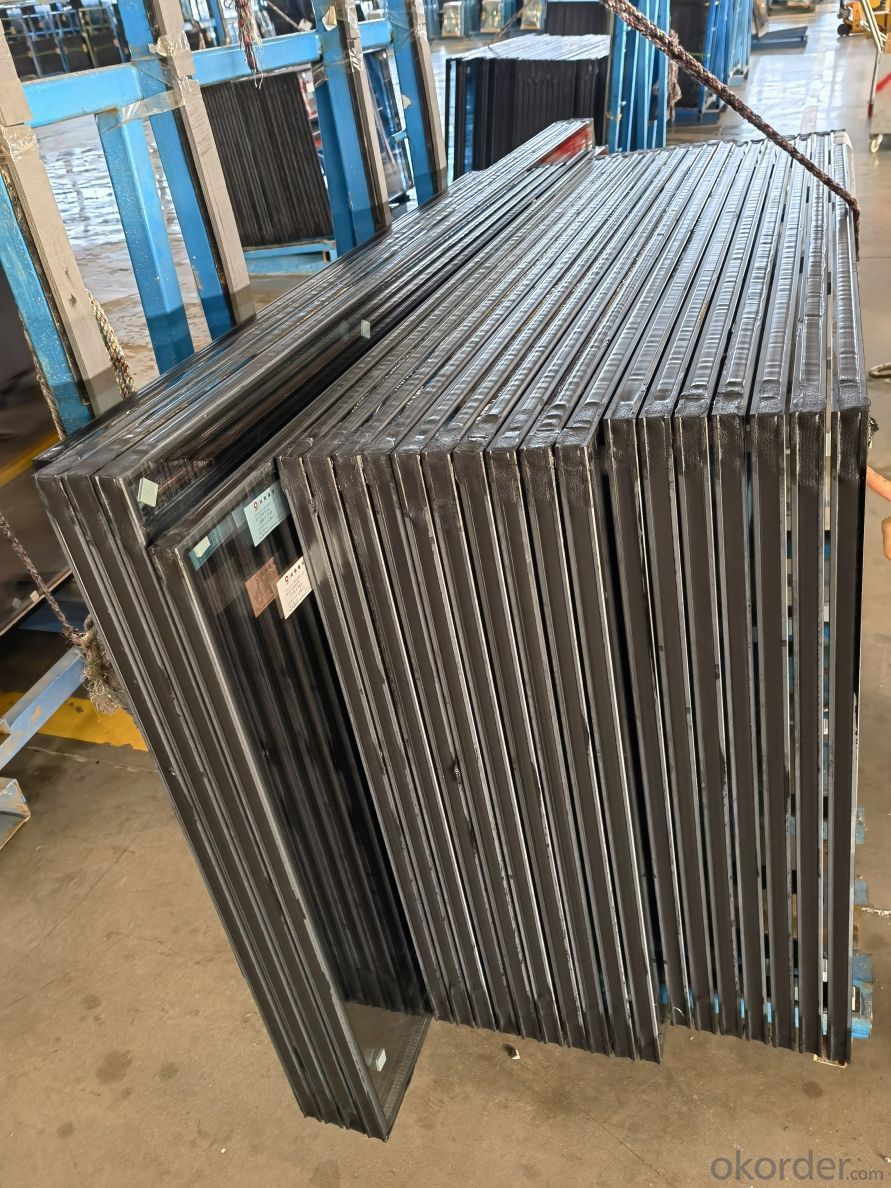

OUR PACKING

Wooden crate, carton box, plastic film, customized, all packing can be fulfilled at QIMINGXING Glass.

professional and experienced working stuff, all packing and loading is guaranteed to be strong and seaworthy to reduce the breakage rate to as low as possible.

Package Type:

1)Inter package is paper or plastic between two sheets;

2)Seaworthy wooden crates;

3) Iron belt for consolidation for insulated glass

Company introduction

CNBM is a subsidiary of China National Building Materials Group Co., LTD., one of the World's top 500 enterprises CNBM line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights. It is equipped with a melting furnace, tin bath, annealing furnace, and cold end cutting system suitable for the production of borosilicate glass. There are well-known international brands suitable for cutting and edging of borosilicate glass in Italy, and the latest tempering furnace in Finland. The company mainly produces borosilicate 3.3 heat-resistant glass and borosilicate 4.0 fire-resistant glass.

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: what is the price

- Fire - resistant flame retardant PVC pipe ~

- Q: Decoration decoration materials, fire performance in line with the technical standards of fire how to apply for documents?

- Supplier of the test report (a qualified inspection agency issued, preferably the National Fire Building Materials Quality Inspection and Supervision Center report), some places require on-site sampling, then, according to their flower lambs can be cut off the snow Grinding rules do it.

- Q: What is the fire cut off?

- To avoid the spread of fire

- Q: Do you need to do floor fire isolation? There are those regulations for fire protection

- 6.2.9 The shaft of the elevator shaft in the building shall meet the following requirements: 1 The elevator shaft shall be set independently. No combustible gas and A, B and C liquid piping shall be laid in the well, and no cables and wires shall be laid. In addition to the installation of elevator doors, safety escape doors and ventilation holes, should not set other openings; 2 cable wells, pipe wells, flue gas, exhaust, garbage Road and other vertical shaft, should be set independently The The fire resistance of the borehole wall shall not be less than 1.00h and the inspection door on the wall of the shaft shall be of Class C fireproof door. 3 The cable wells and pipe wells in the building shall use non-combustible materials not less than the fire resistance of the floor at each floor Or fire blocking material plugging. The construction of the cable wells, pipe wells and rooms, walkways and other connected pores should be used to block the fire blocking material; 4 buildings within the garbage should be set by the external walls of the garbage should be directly open to the outdoor, Garbage bucket should be made of non-combustible materials, and should be able to shut down; outdoor billboards should not be blocked the construction of the window, should not affect the external fire rescue operations.

- Q: In addition to rock wool sandwich panels which plate

- Foam glass plate Glass wool board Expanded perlite plate

- Q: How to brush fire paint

- 1, before the construction must be on the base (coated material) to clean up, remove the ash, oil and paint to be debris. Wood base should reach the natural dry state, water content <10%. 2, stir even after brushing to ensure the construction quality and product performance. 3, should be above 5 ℃, within 24 hours after construction to avoid rain. 4, the coating is generally coated with two layers, if necessary, can be coated with three layers, or cover the light again, Tu finished the first time, the natural dry after the next layer of construction. Every time the brushing surface shall not be leaked. Per square meter with the amount of ≥ 500g, to a fire safety standards. 5, brushing process using brush, spray or roller, brushing evenly. Brush the direction to be consistent, do not cross or repeatedly brushing. Note winter construction should be above 5 ℃, summer should be below 35 ℃, to avoid freezing or overheating.

- Q: Fire-resistant coatings are generally water-based or oily

- Common fire-resistant coatings on the market are also water-soluble (oily). Fire retardant coating from the dispersion medium can be divided into: water and solvent-based two. Water-based fire retardant coating: water as a dispersion medium, the emulsion for the film-forming material, in a variety of flame retardants, filler composition of water-based fire retardant coating. Solvent (oil) fire retardant coating: organic solvent for the thinner, resin for the film-forming material, in a variety of flame retardants, fill the composition of solvent-based fire retardant coating. The difference between the two: water-based fire retardant paint green, environmentally friendly fire-resistant coating, is the national and industry recommended species. Solvent-based fire retardant coating because of the organic film in the process of drying, benzene, xylene and other needs to be volatile, so people and the environment have a certain impact, but in a certain environment, solvent-based fire retardant coating fire resistance, water resistance Chemical resistance is water-based fire retardant coating can not reach. With the continuous progress of technology, the future may be completely eliminated solvent-based fire retardant coating.

- Q: What is a level of fire. Secondary fire, three fire (steel)

- Code for building design fire protection

- Q: Is the soundproof cotton a fireproof material?

- There is fire, there is no fire.

- Q: What are the fireproof materials for Class A roof insulation?

- At present, only phenolic board can meet the requirements, the test temperature of 2000 degrees, no droplets, good integrity. The thermal conductivity of non-combustible, non-toxic, smoke-free!

Send your message to us

Tempered glass 10mm 12mm heat resistant unbreakable

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords