best selling high borosilicate heat resistant glass in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

best selling high borosilicate heat resistant glass in China

Advantages of Heat Resistant Glass

The main advantage of Heat Resistant glass is that it helps in insulation by reducing the heat gain and heat loss. Adding multiple layers of glass with gas infill further protects the windows and building from heat loss.

Another advantage of Heat Resistant glass is that it increases the energy efficiency in buildings. The reduced heat transfer lowers the electrical power consumption required for heating or cooling of the space. This drastically cuts down the electrical bills especially in areas subjected to extreme heat or cold. The use of low-e glass and reflective coatings can further improve the efficiency of the windows by further limiting the heat transfer.

Heat Resistant glass also helps in sound insulation and improves the acoustics of the place. The inert gas present in between the two panes of glass does not allow noise to pass through and acts as a barrier between the interiors of the building and the noise that is present outside the building .

The factory mainly produces

Borosilicate 3.3 heat-resistant glass is widely used in household appliances, electronics, instrumentation, optics, aerospace and other fields.

Borosilicate 3.3 heat-resistant glass has good thermal properties, mechanical properties, optical properties and ultra-high chemical stability. The visible light transmittance is 92%, and the high light transmittance in the near-infrared and ultraviolet bands exceeds 90%. The sign of fluorescence is far lower than that of soda lime glass.

1)Water resistance (International Organization for Standardization 719): Grade A

2)Acid resistance (International Organization for Standardization 195): Grade A

3)Alkali resistance (International Organization for Standardization 695): Grade B

The thickness of the glass ranges from 2.5mm to 15mm, and the maximum size can reach 4800mm×2440mm.

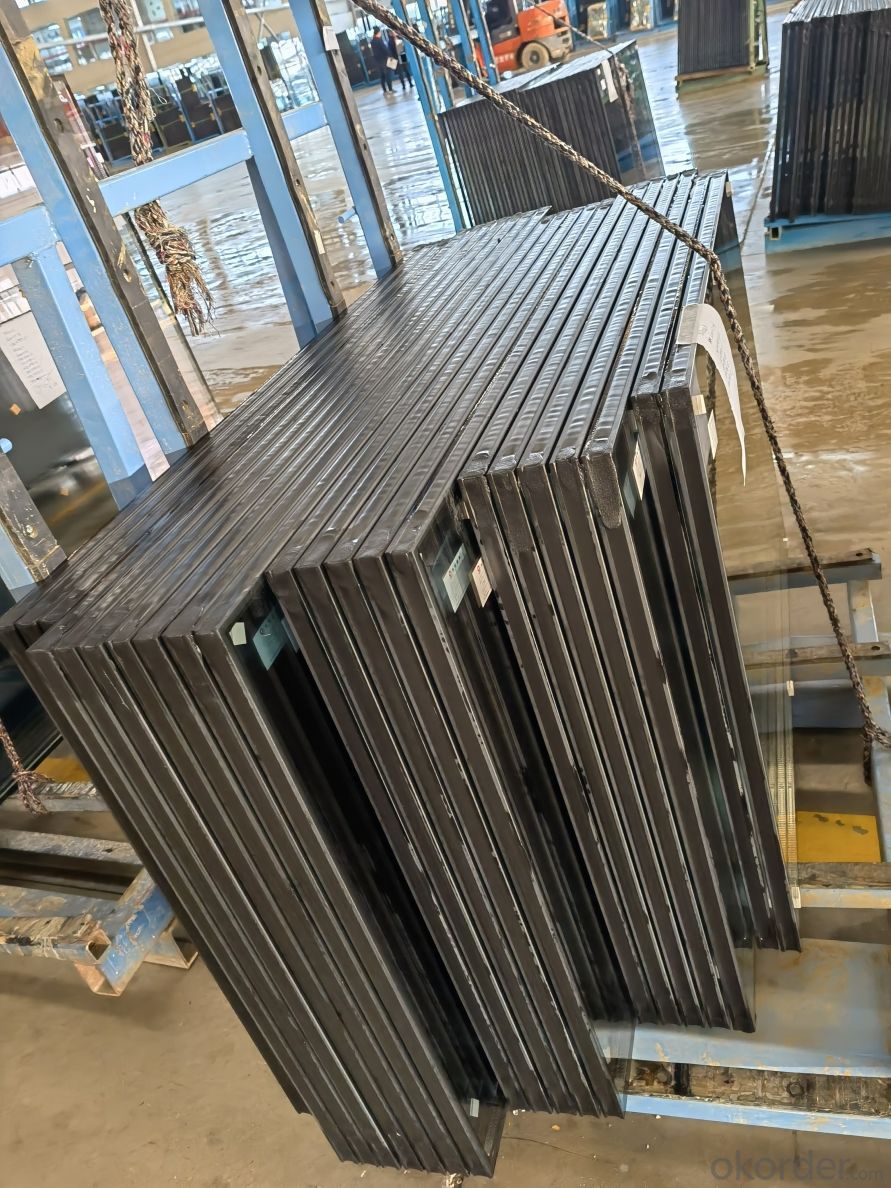

Packing & Delivery

* For small quantities, you can choose DHL or FedEx. It is safe and fast. We have a good rate withthem. Please contact us for

rates.

* Ocean Shipment is economical for big quantity.

* We can also help Custom clearance at destination port and deliver goods to your warehouse or office. And the cost is extra.

Company introduction

CNBM is a subsidiary of China National Building Materials Group Co., LTD., one of the World's top 500 enterprises CNBM line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights. It is equipped with a melting furnace, tin bath, annealing furnace, and cold end cutting system suitable for the production of borosilicate glass. There are well-known international brands suitable for cutting and edging of borosilicate glass in Italy, and the latest tempering furnace in Finland. The company mainly produces borosilicate 3.3 heat-resistant glass and borosilicate 4.0 fire-resistant glass.

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: Ventilation duct fan outsourcing fireproof material specifically what

- 8.5.6 Ventilation, air conditioning system piping, etc., should be made of non-burning materials, but contact with corrosive media duct and flexible joints, can be made of refractory materials. 8.5.7 Insulation materials, silencers and adhesives for pipes and equipment shall be non-combustible materials or refractory materials. Through the firewall and deformation of the duct on both sides of the 2.00m should be used within the scope of non-combustion materials and binders. 8.5.8 When the electric heater is installed in the duct, the fan shall be interlocked with the electric heater. Electric heater before and after the 800mm within the duct and through the fire source and other parts of the pipeline through the fire, must use non-combustible insulation materials fire retardant coating, fire sealant...

- Q: Do you need to do floor fire isolation? There are those regulations for fire protection

- 6.2.9 The shaft of the elevator shaft in the building shall meet the following requirements: 1 The elevator shaft shall be set independently. No combustible gas and A, B and C liquid piping shall be laid in the well, and no cables and wires shall be laid. In addition to the installation of elevator doors, safety escape doors and ventilation holes, should not set other openings; 2 cable wells, pipe wells, flue gas, exhaust, garbage Road and other vertical shaft, should be set independently The The fire resistance of the borehole wall shall not be less than 1.00h and the inspection door on the wall of the shaft shall be of Class C fireproof door. 3 The cable wells and pipe wells in the building shall use non-combustible materials not less than the fire resistance of the floor at each floor Or fire blocking material plugging. The construction of the cable wells, pipe wells and rooms, walkways and other connected pores should be used to block the fire blocking material; 4 buildings within the garbage should be set by the external walls of the garbage should be directly open to the outdoor, Garbage bucket should be made of non-combustible materials, and should be able to shut down; outdoor billboards should not be blocked the construction of the window, should not affect the external fire rescue operations.

- Q: In addition to rock wool sandwich panels which plate

- There are magnesia board, mineral wool board, etc., are flame retardant

- Q: What is the thickness of the thick fireproof coating?

- According to GB-2002 "steel structure fire retardant coating" provisions: thick: coating thickness of 745mm in the fire retardant coating: coating thickness of 3-7mm in the fire retardant coating: the thickness of less than 3mm coating thickness of the fire Type fire retardant coating is non-intumescent steel structure fire retardant coating, generally by: binder, inorganic refractory insulation materials, additives and other components. The coating does not expand in the case of fire, through its own insulation performance of the protected components to improve the fire resistance time.

- Q: Today, see the Christine plant more broken off the German vouchers fan of the CCTV news channel reported that the district energy-saving transformation, the workers are more tense, the first use is to meet the A-class thermal insulation materials, later said to be polyurethane insulation board, and then use the fire A little moment on the smoke, and quickly took the fire machine, then smoke did not burn out, repeated several times did not dare how, this insulation board really fire? More

- Polyurethane insulation board after flame retardant treatment up to B1 level, is unable to achieve A pole fire conditions. Polyurethane is a good performance of synthetic materials, it has a higher strength, thermal conductivity, etc., mainly used for thermal insulation materials, followed by structural materials. Combustion performance for the A-class insulation materials: rock wool, glass wool, foam glass, foam ceramic, foam cement, closed-cell perlite and so on. Combustion performance for the B1 level of insulation materials: special treatment of extruded polystyrene board (XPS) / special treatment of polyurethane (PU), phenolic, powder polystyrene particles. Burning properties of B2 grade insulation materials: molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE) and so on.

- Q: Guiqiu big god, online and other urgent! Will hydration of calcium silicate heat dehydrate to change calcium silicate?

- meeting. Calcium silicate is a fireproof material

- Q: Rock wool board for building fireproof materials need to test what the project, according to what is the specification?

- Detection of resistance to the resistance of the pole melon Cabernet Sauvignon graffiti pressure resistance Tensile thermal conductivity of water and hydrophobicity (to determine whether the rock wool) Our factory is selling pure rock wool board, the specific contact me

- Q: What are the standards for national fire-resistant materials?

- 1, the design of fire safety norms 2, the fire alarm system construction acceptance norms 3, automatic sprinkler system construction 5, building fire facilities testing procedures listed above are the national standard or ministerial standards and local norms such as:

- Q: B1 refractory material refractory time long?

- At present, there are five main grades of fire protection: Class A: non-combustible building materials, almost no burning material. A1 level: non-combustible, can not afford to fire A2 level: non-combustible, to measure smoke, to qualified. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. It is in the air in case of fire or in the role of high temperature difficult to fire, it is not easy to spread, and when the fire destroyed after the fire immediately stop. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable building materials, without any flame retardant effect, easy to burn, fire a great danger. In addition, according to different standards, the classification of fire materials are not the same: DIN4102: A1, A2, B1, B2, B3EN-1: A1, A2, B, C, D, E, FB1 fireproof materials, refractory time Look at the specific parts, see the following figure:

- Q: Outdoor steel ladder as a fire evacuation ladder has any requirements

- Hello: If you are building high-level, then apply "high rules", if it is multi-layer, you should apply "rules." The requirements for the evacuation of the outdoor steel staircase should be strictly regulated, as follows: "High-rise civil building design fire safety regulations" 6.2.10: Outdoor staircase can be used as the anti-smoke staircase The minimum net width should not be less than 0.90m. When the tilt angle is not greater than 45 °, the height of the railings is not less than 1.10m, the outdoor staircase width can be included in the total width of the evacuation staircase. Outdoor staircase and each floor of the exit platform, should be made of non-combustible materials. The fire resistance of the platform should not be less than 1.00h. In the wall around the stairs around 2.00m, in addition to evacuation door, should not open other doors, windows, holes. The evacuation doors shall be of Class B fire doors and shall not be on the stairs. 7.4.5: outdoor stairs can be used as evacuation staircase when the following requirements: 1 railings should not be less than the height of 1.1m, the net width of the stairs should not be less than 0.9m; 2 tilt angle should not be greater than 45 ° ; 3 stairs and platform should be made of non-combustible materials. The fire resistance of the platform should not be less than 1.00h, the fire resistance of the staircase should not be less than 0.25h; 4 doors to the outdoor staircase should adopt Grade B fire doors and should be opened to the outside; Around the wall within 2m should not be set on the door and window openings. The evacuation door should not be on the stairs. Hope it helps you!

Send your message to us

best selling high borosilicate heat resistant glass in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches