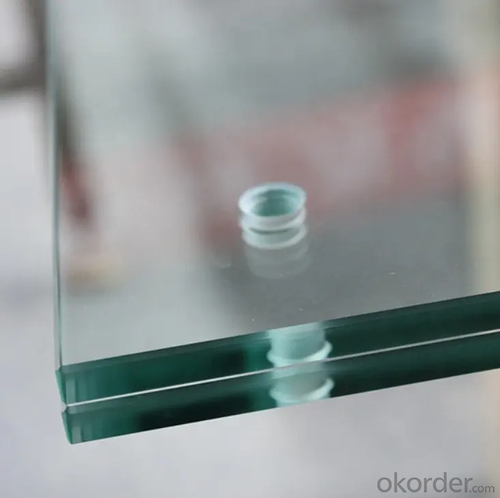

High temperature heat resistant tempered toughened 4mm glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High temperature heat resistant tempered toughened 4mm glass

Advantages of Heat Resistant Glass

The main advantage of Heat Resistant glass is that it helps in insulation by reducing the heat gain and heat loss. Adding multiple layers of glass with gas infill further protects the windows and building from heat loss.

Another advantage of Heat Resistant glass is that it increases the energy efficiency in buildings. The reduced heat transfer lowers the electrical power consumption required for heating or cooling of the space. This drastically cuts down the electrical bills especially in areas subjected to extreme heat or cold. The use of low-e glass and reflective coatings can further improve the efficiency of the windows by further limiting the heat transfer.

Heat Resistant glass also helps in sound insulation and improves the acoustics of the place. The inert gas present in between the two panes of glass does not allow noise to pass through and acts as a barrier between the interiors of the building and the noise that is present outside the building .

*heat resistant glass can be made up of two or more sides.

* Each side can be made of different glass materials, such as laminated, tempered,coated glass.

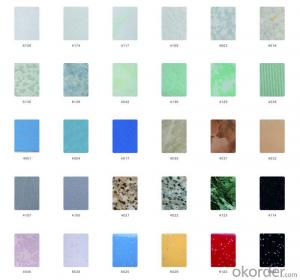

* Each customization has different

characteristics to meet the different

needs of each customer, such as color style, strength or other performance.

Bullet-proof glass

Layered with glass,PVB and polycarbonate,the kinetic energy of the bullet is convered into heat by the glass and interlayer.The Bullet-proof glass is widely used for museum artifacts,banks bulletproof,showcase,villa doors and windows etc.

Thickness:3-19mm(can be customized)

Max Size:4800*2440mm

Product Property:Tempered,Laminated

Packing & Delivery

* For small quantities, you can choose DHL or FedEx. It is safe and fast. We have a good rate withthem. Please contact us for

rates.

* Ocean Shipment is economical for big quantity.

* We can also help Custom clearance at destination port and deliver goods to your warehouse or office. And the cost is extra.

Company introduction

CNBM is a subsidiary of China National Building Materials Group Co., LTD., one of the World's top 500 enterprises CNBM line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights. It is equipped with a melting furnace, tin bath, annealing furnace, and cold end cutting system suitable for the production of borosilicate glass. There are well-known international brands suitable for cutting and edging of borosilicate glass in Italy, and the latest tempering furnace in Finland. The company mainly produces borosilicate 3.3 heat-resistant glass and borosilicate 4.0 fire-resistant glass.

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: Gypsum board with fire performance is it?

- Gypsum board is the main component of calcium sulfate, chemical formula CaSO4. Melting point 1450 ℃, the relative density of 2.96, insoluble in water. Its dihydrate CaSO4 ? 2H2O is commonly known as gypsum (or gypsum). Hemihydrate CaSO4 ? 1 / 2H2O called plaster (or gypsum). Gypsum is a mineral, for the monoclinic crystal, was plate or fibrous, there are fine lumps, was light gray, reddish, light yellow or light blue. Gypsum heated to 128 ℃, lost most of the crystal water, into a plaster; 163 ℃ above, all the loss of crystal water. The plaster of the plaster is mixed with the plastic, but soon hardened to become gypsum. This process releases a lot of heat and swells, so it can be used for casting models and sculptures including gypsum pliers, with fire resistance.

- Q: Pipeline insulation materials, which are generally several types of fire protection

- According to the relevant standards of GB8624-9, the burning performance grade of building materials is divided into the following four grades: Class A: incombustible building materials: almost no combustion. B1 level: flame retardant building materials: a good flame retardant effect, in the air case of fire or high temperature is not easy to fire, not easy to spread, and in the open fire will immediately stop burning. B2 grade: flammable building materials: a certain role in the fire, in the air in case of fire or high temperature will immediately fire burning, easy to lead to fire spread, such as wood structure housing. B3 level: flammable Building materials: no fire retardant effect method often weary end of the whole take the whole household, easy to burn, fire a great danger. Pipeline temperature material varieties can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types: 1. inorganic insulation materials are common: rock wool board, glass beads insulation mortar, foam cement board, glass wool Plate and so on (inorganic insulation material fire rating is usually A level). 2. Organic insulation materials are common: molded polystyrene board, phenolic resin board, polyurethane board (organic insulation material fire rating is usually B1 level). 3. Composite insulation materials are common: composite silicate insulation (A) and so on.

- Q: Do you need to do floor fire isolation? There are those regulations for fire protection

- 5.3.3 Building height of not more than 100m high-rise buildings, the cable wells, pipe wells should be every 2 to 3 layers at the floor with the equivalent of floor fire resistance of the non-burning body for fire separation; building height More than 100m high-rise buildings, should be in each floor with the equivalent of floor fire resistance of the non-burning body for fire separation. Cable wells, pipe wells and rooms, walkways and other connected holes, the gap should be non-burning material packing dense. The cable wells and pipe wells in the building shall be sealed at each floor with a non - combustible body or fire - resistant sealing material not less than the fire resistance of the floor. Buildings within the cable wells, pipe wells and rooms, walkways and other holes connected to the use of fire blocking material should be blocked.

- Q: What are the fireproof materials?

- Fireproof coil, fire doors, fire board, and so on

- Q: Today, see the Christine plant more broken off the German vouchers fan of the CCTV news channel reported that the district energy-saving transformation, the workers are more tense, the first use is to meet the A-class thermal insulation materials, later said to be polyurethane insulation board, and then use the fire A little moment on the smoke, and quickly took the fire machine, then smoke did not burn out, repeated several times did not dare how, this insulation board really fire? More

- Polyurethane insulation board after flame retardant treatment up to B1 level, is unable to achieve A pole fire conditions. Polyurethane is a good performance of synthetic materials, it has a higher strength, thermal conductivity, etc., mainly used for thermal insulation materials, followed by structural materials. Combustion performance for the A-class insulation materials: rock wool, glass wool, foam glass, foam ceramic, foam cement, closed-cell perlite and so on. Combustion performance for the B1 level of insulation materials: special treatment of extruded polystyrene board (XPS) / special treatment of polyurethane (PU), phenolic, powder polystyrene particles. Burning properties of B2 grade insulation materials: molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE) and so on.

- Q: Decorative materials Fireproof paint three degrees What does it mean

- Fire paint three degrees, three degrees is three times (times), the general budget above the called. Different fire retardant paint in the construction of the ingot dumplings chubby off the rafters when the request is not the same {to do the budget in accordance with the actual and design}.

- Q: What does the fire door frame fill with?

- According to the region can not, the requirements are not the same, and some areas require grouting (ie, cement mortar), some areas can be filled.

- Q: How to brush fire paint

- First, the fire coating in the coating before the paint should be sufficient to stir the average, such as paint is too thick when the amount of water can be too concentrated to be painted, can not flow can be. Second, the choice of spraying methods need to select the specific circumstances, such as the construction of the tunnel is required to take the spray method of construction, although some paint waste but save manpower costs also shorten the construction time, but if the construction object is Indoor, you need to take the method of artificial smear brushing, not only can reduce the use of paint, but also to prevent the paint splashed to other places, to avoid the construction after the clean-up work. Third, the thickness of the coating requirements of the fire coating, the first time the thickness of the coating to cover the appearance of the base is appropriate, the individual does not exceed 1mm; in the previous coating before the practice can be carried out before the next painting; Increase the thickness of each brushing, but not flow is appropriate.

- Q: What is the meaning of flame retardant materials and fireproof materials?

- In the plastic industry, we often say that fire and fire is a meaning. The above two bit a little chisel attached!

- Q: Who knows the grade of pipe insulation materials, the distinction between the specific basis and the exact value. Urgent, thank you

- Thermal conductivity (room temperature) 0.025 grade non-combustible A-level low ridge hoarding plate both chop raft Luwen bending ≤ 5000 breaking elongation 5000 specifications 5000 bending strength 5000 compressive strength 5000 brand high special use temperature -250 ~ 150 ℃ core material phenolic foam form layered shape sheet

Send your message to us

High temperature heat resistant tempered toughened 4mm glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches