Packaging Tape Machines for BOPP Adhesive Tape, Masking Tape, and Stationery Glue Tapes

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CONSTRUCTION:

Carrier: BOPP film

Adhesive: Water based acrylic adhesive.

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + carrier): 42 ± 1 um

Adhesive thickness:20 ± 1 um

Initial Tack: ³ 23#

180O Peel Adhesion (to steel): ³ 6.52 N /25mm

Holding Power: ³ 31 hrs

PACKING:

Core I.D.: 3” (76mm±1)

Jumbo Roll:1280mm x 4000m

Cut Roll: As per customer’s requirements

Application:

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

REMARKS:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and be kept away wet and/or heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

TAPE FAQ

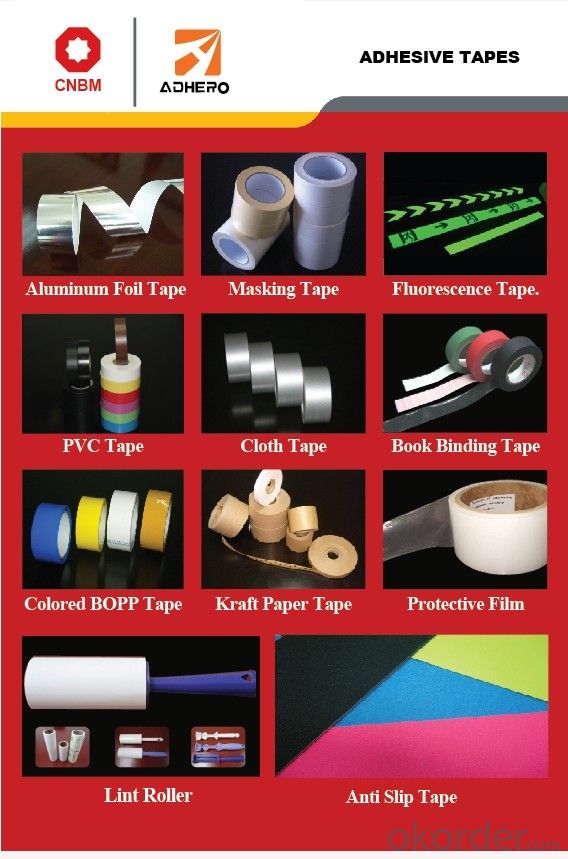

What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

Can Adhero accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

What are the international commodity codes for these products?

HS Code: 48231900.

Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

What are the temperatures resistances of your masking tape?

we have two general kinds of masking tapes separately for general purpose 60°C and high temperature 100°C to 160°C.

Are you a manufacturer or just a trader?

We are a professional manufacturer.

How about the quality?

The quality is very good. We have large and advanced product line.welcome to visit our company.

- Q: How do I prevent packaging tape from wrinkling?

- To prevent packaging tape from wrinkling, there are a few things you can do: 1. Use a tape dispenser: A tape dispenser helps ensure a smooth application of tape, reducing the chances of it wrinkling. It also provides better control while taping, making it easier to keep the tape straight and tight. 2. Apply the tape with tension: When applying the tape, pull it tightly as you stick it down. This helps prevent any slack or loose areas that could cause wrinkling. Be careful not to stretch the tape too much, as it may lose its adhesive properties. 3. Use the right type of tape: Different types of packaging tape have different adhesive properties and thicknesses. Choosing a high-quality tape specifically designed for packaging can help minimize wrinkling. Additionally, consider using a tape with reinforced fibers for added strength and resistance to wrinkling. 4. Ensure a clean surface: Before applying the tape, make sure the surface is free from dust, dirt, or any other debris. These particles can cause the tape to wrinkle or not adhere properly. Clean the surface thoroughly and dry it before taping. 5. Avoid extreme temperatures: Packaging tape can be sensitive to temperature changes, which may lead to wrinkling. Avoid using the tape in extremely cold or hot environments. If possible, store the tape in a controlled temperature area before use. 6. Apply pressure: After applying the tape, run your hand or a roller over it to ensure good adhesion. This helps smoothen out any potential wrinkles or bubbles and ensures that the tape is securely attached. By following these tips, you can significantly reduce the chances of packaging tape wrinkling, resulting in a neater and more secure package.

- Q: Can packaging tape be used for sealing plastic storage jars?

- Yes, packaging tape can be used for sealing plastic storage jars. Packaging tape is designed to provide a strong and secure seal, making it suitable for various applications including sealing plastic storage jars. It can effectively keep the contents of the jar protected and prevent any leakage or contamination. However, it is worth noting that there are other options specifically designed for sealing jars, such as jar lids and seals, which may provide a more secure and airtight seal.

- Q: Can packaging tape be used for sealing foam or bubble wrap?

- Certainly! Sealing foam or bubble wrap is indeed possible with packaging tape. This type of tape is specifically engineered with a potent adhesive that effectively sticks to different surfaces, such as foam and bubble wrap. To securely seal and safeguard your belongings during transportation or storage, simply affix the packaging tape onto the edges or seams of the foam or bubble wrap. It is crucial to ensure that the tape is correctly and firmly applied to achieve a snug seal, preventing any possibility of the foam or bubble wrap coming undone.

- Q: Can packaging tape be used for sealing packages with irregular or uneven surfaces?

- Yes, packaging tape can be used for sealing packages with irregular or uneven surfaces. Packaging tape is designed to adhere to various types of surfaces, including those that may be uneven or irregular. The strong adhesive properties of packaging tape ensure that it securely seals the package, even on surfaces that may not be completely flat or smooth. Additionally, packaging tape is flexible and can conform to the shape of the package, allowing for effective sealing on irregular surfaces. However, it is important to ensure that the tape is applied evenly and pressed firmly onto the surface to maximize its sealing capabilities.

- Q: What are the considerations for using packaging tape on corrugated cardboard boxes?

- When using packaging tape on corrugated cardboard boxes, it is important to consider the strength and durability of the tape, as well as its adhesive properties. The tape should be strong enough to securely seal the box and withstand any potential stress or weight during handling and transportation. Additionally, the tape's adhesive should be able to adhere well to the corrugated surface and provide a tight seal, preventing any contents from shifting or falling out. It is also advisable to choose a tape that is easy to apply and tear, ensuring efficient packaging processes.

- Q: Can packaging tape be used for sealing recreational or outdoor gear?

- Yes, packaging tape can be used for sealing recreational or outdoor gear. Packaging tape is designed to securely seal boxes and packages, providing a strong and durable seal. It can be used to repair tears or holes in gear such as tents, sleeping bags, backpacks, or tarps. Additionally, packaging tape can be used to reinforce weak points or seams in gear, adding extra strength and protection. However, it is important to note that while packaging tape can provide a temporary fix, it may not be as long-lasting or weather-resistant as specialized outdoor repair tapes. It is always recommended to use the appropriate gear repair products for a more reliable and durable solution.

- Q: Does packaging tape leave residue?

- Yes, packaging tape can leave residue on surfaces after it is removed.

- Q: Is packaging tape waterproof?

- Typically, packaging tape possesses waterproof properties. Its design aims to resist moisture effectively and create a formidable seal, thereby preventing water infiltration into the package. Nonetheless, it is crucial to acknowledge that the degree of waterproofing can vary depending on the quality and type of packaging tape employed. Certain tapes may offer a more reliable seal compared to others, hence it is advisable to opt for a tape explicitly crafted for packaging and sealing applications.

- Q: Does packaging tape come in different colors for organization purposes?

- Yes, packaging tape does come in different colors for organization purposes. Many companies offer packaging tape in various colors such as red, blue, green, yellow, and black. These different colors can be used to categorize and organize different types of packages or to differentiate between shipments going to different destinations. It can be particularly useful in warehouses or shipping departments where multiple packages need to be identified and sorted easily. Additionally, colored packaging tape can also be used for decorative purposes, such as gift wrapping or creating visually appealing packaging for retail products.

- Q: Can packaging tape be used for sealing plastic storage bags?

- Yes, packaging tape can be used for sealing plastic storage bags. It provides a strong adhesive bond that helps keep the bags securely sealed.

Send your message to us

Packaging Tape Machines for BOPP Adhesive Tape, Masking Tape, and Stationery Glue Tapes

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords