Packaging Tape Walmart - Stationery Glue, BOPP Adhesive Tape, Masking Tape Tapes

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CONSTRUCTION:

Carrier: BOPP film

Adhesive: Water based acrylic adhesive.

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + carrier): 42 ± 1 um

Adhesive thickness:20 ± 1 um

Initial Tack: ³ 23#

180O Peel Adhesion (to steel): ³ 6.52 N /25mm

Holding Power: ³ 31 hrs

PACKING:

Core I.D.: 3” (76mm±1)

Jumbo Roll:1280mm x 4000m

Cut Roll: As per customer’s requirements

Application:

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

REMARKS:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and be kept away wet and/or heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

Advantage to recommend:

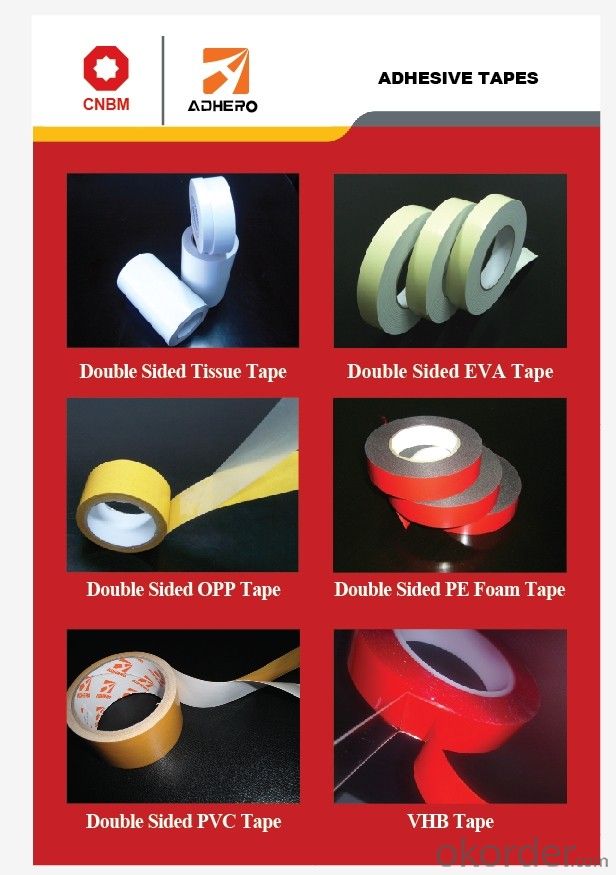

We supply a wide range of products, which include double sided adhesive tape, masking tape, kraft tape, cloth tape, BOPP tape and so on.

Our biggest item is double side tape. Our double-sided adhesive tapes are with the carriers of tissue, PET, OPP, cloth, PE foam and EVA foam. And the adhesives involved are water based, solvent based and hot-melt acrylic adhesive.

According to different temperature resistances, we have two categories of masking tapes separately for general purpose and high temperature from 100°C to 160°C.

We also produce kraft tape, cloth tape and BOPP tape.

We have as our principle “Clients’ need comes first”. So we have a good variety of technical properties and sizes to meet with your different needs.

Our products enjoy popularity in markets because they have super quality with competitive price and good service.

Adhero is your ideal choice for excellent adhesive tapes and solutions.

TAPE FAQ:

What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

Can Adhero accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

What are the international commodity codes for these products?

HS Code: 48231900.

Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

What are the temperatures resistances of your masking tape?

we have two general kinds of masking tapes separately for general purpose 60°C and high temperature 100°C to 160°C.

Are you a manufacturer or just a trader?

We are a professional manufacturer.

How about the quality?

The quality is very good. We have large and advanced product line.welcome to visit our company.

- Q: Can packaging tape be used for sealing construction materials or tools?

- Indeed, construction materials or tools can be sealed using packaging tape. The primary purpose of packaging tape is to securely seal boxes and packages, which also makes it effective for sealing construction materials or tools. Its strong and durable bond makes it suitable for sealing a wide range of materials, including wood, metal, plastic, or concrete. Nevertheless, it is crucial to take into account the weight and characteristics of the materials being sealed. In instances where heavier or more challenging construction applications are involved, specialized tapes or adhesives specifically intended for construction purposes might be more suitable.

- Q: Is packaging tape safe to use on plastic cutting boards?

- Packaging tape is indeed a safe option for plastic cutting boards. Its design enables it to stick to various surfaces, including plastic, without causing any harm or damage. It is commonly utilized for sealing packages and boxes, and does not contain any hazardous chemicals or substances that could jeopardize the plastic cutting board or the food being prepared on it. Nevertheless, it is crucial to acknowledge that utilizing packaging tape on a cutting board is not advised for reasons related to food safety. To avoid potential contamination, it is recommended to employ food-grade materials like food-safe adhesive tape or rubber bands to secure plastic cutting boards.

- Q: Does packaging tape come in different widths for sealing different-sized items?

- Yes, packaging tape does come in different widths for sealing different-sized items. This allows for flexibility and customization when it comes to packaging and sealing various items. Depending on the size and weight of the item being packaged, one can choose from a range of widths for packaging tape. For smaller items or lightweight packages, narrower widths such as 1-inch or 2-inch tapes might be sufficient. On the other hand, for larger items or heavier packages, wider widths like 3-inch or 4-inch tapes may be more suitable to ensure secure sealing. The availability of different widths in packaging tape ensures that it can be used effectively for sealing different-sized items, providing optimal protection during storage and transportation.

- Q: Does packaging tape come in different eco-friendly options?

- Yes, packaging tape is available in different eco-friendly options. Many companies now offer packaging tape made from recycled and biodegradable materials, such as paper or plant-based adhesives. These eco-friendly alternatives help reduce the environmental impact of packaging materials.

- Q: Does packaging tape come in different patterns or designs?

- Yes, packaging tape does come in different patterns and designs.

- Q: Does packaging tape have a specific adhesive strength?

- Yes, packaging tape does have a specific adhesive strength. The adhesive strength of packaging tape refers to how well it sticks to surfaces. This strength is typically measured in ounces per inch (oz/in) or pounds per inch (lb/in). The adhesive strength of packaging tape is determined by various factors, such as the type of adhesive used, the thickness of the tape, and the quality of the backing material. Different types of packaging tape may have different adhesive strengths to cater to specific needs, such as lightweight packages or heavy-duty shipments. It is important to consider the intended use and the weight of the package when choosing packaging tape with the appropriate adhesive strength.

- Q: Is packaging tape safe to use on plastic cutting mats?

- Yes, packaging tape is generally safe to use on plastic cutting mats. However, it is important to ensure that the adhesive used in the tape does not contain any harmful chemicals that could potentially damage or contaminate the plastic surface of the cutting mat. It is recommended to check the manufacturer's instructions or do a patch test on a small area of the mat before applying the tape extensively.

- Q: Can packaging tape be used for sealing pet food or treats?

- Yes, packaging tape can be used for sealing pet food or treats. It provides a strong and secure seal to keep the contents fresh and protected. However, it is important to ensure that the tape used is safe for pets, meaning it should be non-toxic and not contain any harmful substances that could potentially be ingested by the animals. It is recommended to use pet-safe packaging tape specifically designed for sealing pet food or treats, as it meets the necessary safety requirements and regulations.

- Q: Is packaging tape resistant to extreme pressure or weight?

- Packaging tape is designed to provide a strong and secure seal for packages, but its resistance to extreme pressure or weight can vary depending on the specific type and quality of the tape. Generally, packaging tapes are made from durable materials like polypropylene or polyester that can withstand typical handling and transportation pressures. However, it is important to note that packaging tape may not be able to withstand extremely heavy loads or excessive pressure. In such cases, it is recommended to reinforce the tape with additional layers or use specialized heavy-duty tapes that are specifically designed for high-pressure or weight-bearing applications.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is typically designed to be easily removed without causing any harm to surfaces. However, the ease of removal can vary depending on several factors, including the type and quality of the tape, the surface it is applied to, and how long it has been in place. Most packaging tapes are created to stick firmly to surfaces during transportation or storage, ensuring that the package remains sealed and secure. Nevertheless, they are also formulated to be peeled off easily when necessary, without leaving any residue or causing damage. In most situations, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is generally developed to strike a good balance between sticking power and ease of removal. This allows for effortless removal without the need for excessive force or any sticky residue. However, there may be instances where the tape might be more challenging to remove, particularly if it has been in place for a long time or exposed to extreme temperatures. In such cases, using heat, such as a hairdryer, to soften the adhesive can be helpful, making it easier to peel off. It is important to note that the ease of tape removal can also be influenced by the surface it is applied to. Smooth and non-porous surfaces like glass or metal are generally easier to clean without causing any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to prevent any potential damage. In conclusion, while packaging tape is generally designed to be easily removed without causing damage, it is essential to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

Send your message to us

Packaging Tape Walmart - Stationery Glue, BOPP Adhesive Tape, Masking Tape Tapes

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches