Tact Switch

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 80000000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tact Switch ,Push button Switch ,Pressure Switch ,tactile switch

KFCA065HCJ KFCA06TP85 KFCA06ZC5H KFCA06CZJ05H

KFCA

we are producing Push button Switch, Push Switch

Tact Switch, Power Switch ,Micro Switch

Power Tool Switch, Pressure Switch

KFCA065HCJ KFCA06TP85 KFCA06ZC5H KFCA06CZJ05H

KFCA06CLJ05H KFCA0673 KFCD06BH KFCD065872

KFCA06ZJ5H KFCA065J5H TST2435 TS33H

TSY3420 TS3625B1T TS3625B TSTPHM

TSY66H TSX88HN TSX88HS TSF1273

TS4406 TS44H TSTP4515 TSTP45H TS62H

TS66J4 TS11M WSTP050 TSB303 TSG1175

TSG1125 MD1050 TS1131 TS1243X1 TS11T TS1273G2

WSX6543 TSTPJ1212 WSX6543W WS77HS

KFC-A02-01 TDHn KFC-A02-02 Hn KFC-A03-01 THn

KFC-A03-02 Hn KFC-A03-03 THn

KFC-A04-01 Hn KFC-A04-02 Hn KFC-A07-F7.3/D

KFC-A07-10/D TS405 DS-1120A

DS-1120 TSD66 PBS-19C PBS-32B PBS-17A

SW-2-20M SW-3-20M SW-3-20T SW-3-25T

KDC-A04-1-20M KDC-A06 KDC-A10-20T KDC-A11

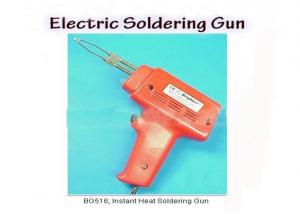

- Q: How much watt is the electric iron for mobile phone maintenance? How much does one need?

- Generally choose the following 50W thermostat. OK, there's Thailand and China. I usually use Gaudi 936A.

- Q: I have a 50 Watt electric iron. Can I solder the chips in my cell phone battery? What can 50 Watt electric irons be used for welding?

- Soldering the chip in the cell phone battery, the 50 Watt electric iron is too big, the 50 Watt electric iron is suitable for welding the big electronic component!

- Q: Electric soldering iron without rosin, what can be used instead?

- Electric soldering iron without rosin can be replaced by solder paste, you can try it, it works well.Soldering paste:Solder paste is a homogeneous mixture consisting of alloy solder powder, paste flux and some additives. It is a paste with a certain viscosity and good thixotropy. At room temperature, solder paste can be glued to the electronic components at the beginning of the fixed position, when heated to a certain temperature, solvent and additives with evaporation, melting alloy powder, the welded components and pads are linked together to form a permanent connection of the solder joint cooling.What's the effect of rosin when using an electric iron?1, cleaning oxide.The rosin can clean the welding wire, the parts to be welded, oxide and other impurities, and strengthen the welding firm strength.2, prevent oxidation.Rosin can isolate solder wire from air and reduce the formation of oxides.3 wettability.Rosin can increase the liquid fluidity of solder wire. Better promote the capillary action of solder.

- Q: What tools do you need to remove and solder this chip? Is it possible to have an electric iron and a tin screw? Don't use hot air guns

- Integrated block, two back row. The technology is good, and can tin suctioner or tin solder cleaning line one by one after the removal of electric iron. However, if the original solder joint is very small and the holes and pins are tight, it is very difficult to remove the tin because it is difficult to clean. You can solder it at once with a hot-air gun.

- Q: How do you get the ground wire of the electric iron? Where do you want to go?

- A handle of the electric iron formal there are three connecting bolts, generally one labeled ground symbol, and the electric iron steel case it is connected by residential ground socket, the power line plug is the tripod. Some homes do not have ground wire, it is necessary to find their own way to receive iron, water pipes or other grounding nature of the conductive material. On the market, a considerable part of the electric iron power cord plug is two feet, there is no ground end.

- Q: How many watt electric irons are used in appliance maintenance? Is it heated inside or outside?

- 60 watt internal heat

- Q: What about the price?

- Heating temperature control station

- Q: Can the electric iron of the school solder aluminium products?

- The welding of aluminium alloys with iron can be made in the case that the aluminum matrix must be very fine, or that aluminum is very thin film. But as long as there is a general aluminum structure and size of certain words, suggestion is to use liquefied petroleum gas porous WE53 special welding gun, and then with a low temperature aluminum welding.That is if you want to weld aluminum is aluminum foil, thin aluminum and other small and thin pieces, can be used for welding or soldering iron, hot air gun, but low wire materials need to use M51 with M51-F flux.Process for soldering electric iron1, the electric iron inserted into the electric heating.2. Adjust the pin of the capacitor and insert it into the printed circuit board3. Apply a small amount of solder paste on the contact between the capacitor pin and the circuit board.4. The iron head of the preheated electric iron is pressed at the contact point between the pin and the circuit board for a moment, so that the local temperature is increased to the melting point of tin wire. The solder wire to the pin contact with the iron head, when the appropriate amount of solder, solder wire removed along the pin element, remove the iron, solder joint into a round.5, diagonal pliers to cut unnecessary stitches, complete the soldering operation. Tip: right between the residence time and the operation steps of soldering a great influence on the welding quality, need to gradually learn in practice.

- Q: Is there any way to solder a copper block to a small wire with an electric iron, and each soldering does not stick?,

- Copper temperature and surface oxidation, coating will affect the welding effect. Polished rough surface is also conducive to adhesion, copper block if a little larger, you can consider heating up, active copper molecules, relatively easy to adhesion

- Q: My electric iron is pointed, want to change a slanting head, but buy a new head can not be installed, trouble expert pointing

- The fixed screw tip in front of the unload iron head will naturally fall out, if it does not come out with pliers and pull it out, after pulling out the new iron head put in, head will be adjusted to the appropriate location, and then OK in the locking screws.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tact Switch

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 80000000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords