BTR-11 Flat Nose Plier 160mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We supply different types of pliers & cutters:

Mini Plastic Nippers / Cutters

Diagonal / Long Nose / Bent Nose Nippers

We are a direct manufacturer of electrical tools with experience of more than 25+ years. With our well experience and the stricted quality control, our company has become famous in many markets over the world. Our annual production quantity is two millions pieces for assorted models.

Agents or distributors wanted. OEM is welcome!!

We supply different types of pliers & cutters:

Mini Plastic Nippers / Cutters, 115mm

Plastic Nipper, 125mm / 150mm

Diagonal Nippers, 115mm

Long Nose Nipper, 150mm / 200mm

Bent Nose Nipper, 150mm

Neddle Nose Nipper, 150mm

Fishing Plier, 160mm

Bent Fishing Plier, 160mm

Big-Head End Cutter, 163mm

Flat Nose Plier, 115mm / 125mm / 160mm

Micro-cutter, 125mm

Electric Heat Nipper

.... etc.

Other products from us:

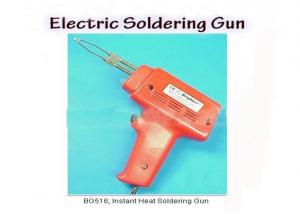

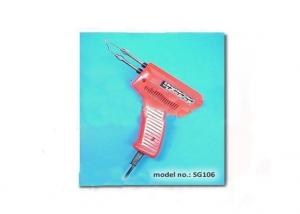

Electric Soldering Irons / Guns

Hot Melt Glue Guns & Glue Sticks

Travel Steamers

Briflon PTFE Adhesive Tape

NeoTech Printer Cartridges

- Q: When the circuit board is hot with the electric iron, some leather can not affect the work? Can you scrape the circuit board with a knife?

- Skin is no problem, as long as there is no broken copper does not affect the function, if the patent under the copper water clock out, there may be damp rust oxidation, if the conditions can make some green paint to prevent oxidation.

- Q: Who knows how to solder two coins together? Either the front or the side. I haven't solder it for days, thank you

- Solder coins?And as the solder iron melt in iron.....Place a small amount of solder paste on the weld and put it on the top

- Q: I replaced a component on the PCB board with a 40W electric iron,Insert the replacement new components into the PCB board,Use the electric iron to heat the horn of the element and place the solder on the other side of the antenna (from left to right: solder, element, horn, electric iron)At this point, the solder melts and runs to the head of the electric iron and does not remain on the antenna of the elementExcuse me, why is this solved?Is it necessary to have rosin around the tentacles first?I don't know if there is any rosin in my solder wire

- Before soldering, it is better to solder each pin to the tin. If you do not hang on the tin, you can first use a knife or sandpaper polished, so that the bright pin, and then rosin hanging tin is much easier. (place the pin on a block of rosin, with tin on the tip of the iron)

- Q: How do you get the ground wire of the electric iron? Where do you want to go?

- A handle of the electric iron formal there are three connecting bolts, generally one labeled ground symbol, and the electric iron steel case it is connected by residential ground socket, the power line plug is the tripod. Some homes do not have ground wire, it is necessary to find their own way to receive iron, water pipes or other grounding nature of the conductive material. On the market, a considerable part of the electric iron power cord plug is two feet, there is no ground end.

- Q: That kind of heating seat has 3 buttons and a switch on it. How can I get it?

- The simplest way is to find a multi stall ceiling fan switch, and then connect the electric iron electric wire. Can meet the requirements. There is also a way to use the power device to do it yourself, and then buy the existing thermostat thermostat iron.

- Q: Can electric soldering iron copper pipe?

- Yes, but if the pressure is great, use it soon if it's a general sight

- Q: Probably is that when the need to frequently go to a variety of audio and video (such as welding head, VGA head lotus head, chuck and so on), it is necessary to use the electric iron and solder wire, and later at the site of welding, could not take welding tools, so that individuals need only electric iron and solder wire is enough.As for the electric iron, my personal preference is to buy the kind of adjustable temperature, solder wire I don't know what kind of good, so, I would like to ask is: temperature adjustable electric iron what brand of good price; I see the solder wire line has said that with the lead, also does not contain lead the diameter is from 0.3mm---1.0mm to see so much, and size of solder wire, containing lead, which brand line is good?

- Yellow Gao Jie temperature control iron, commonly used to buy outside the heat, not used to buy the internal heat, hot, I remember it is 902, the internal heat is 905, as if the front letter forgotten, with 60W hot barFree of lead has no effect on the first, 0.3 and 1 as, with 1.

- Q: It's going to buy an electric iron for wires and some small parts on the electric board in Taobao. Being a beginner, it is purely amateur. I do not know how many tiles to buy, but it is best to dissolve tin hot fast. Internal heat and external heat, pointed flat mouth. Which is more suitable for welding small objects (such as sockets, loose welding, stable points, etc.)? How many watts can both dissolve quickly and not hurt small pieces?

- If it is small enough to weld 50W, I 50W is the commonly used heat type, and more convenient, more suitable for beginners, because the oblique mouth hanging tin iron head is easy, not easy to burn, with a few times if you feel the iron head sunk or burned to the center, the best file repair is better,Which is more suitable for welding small objects?See the computer repair, the electric iron knife they use the (not small, my first feeling is sharp is small special welding, and later learned that it's not so, but may be a good point in specific situations), with little dependence on the size of the electric iron, the most important key. With the usual technology, and those small? Individual feel inclined mouth, most suitable for noviceHow many watts can both dissolve quickly and not hurt small pieces?This is not much to do with watts, as long as the master welding time on the line, the longest is generally not more than 2 - 3 seconds, but feel the number of watts is too small, so that longer welding time, and more likely to damage the device

- Q: Thanks for the help of two friends first! Rosin also added a weld, what is the concept? If the time is too long, what should I do? Let's hang it for a while. OK? What about overheating the soldering iron?

- Just gum rosin

- Q: In fact, about 700 degrees.The highest 800 degree electric iron is needed to fuse the spot welding.Looking for a master to help.

- The ordinary heating iron doesn't have the temperature you say, unless it's high power. I saw 200W. The highest temperature is only 500 degrees celsius!

1. Manufacturer Overview

| Location | Kowloon, Hong Kong |

| Year Established | 1971 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BTR-11 Flat Nose Plier 160mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords