DVI Cable

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Pieces pc

- Supply Capability:

- 800000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDMI cable, DVI cable, VGA cable, Optical fiber cable, USB Cable; Rca cable

The main products of our company are as following:

HDMI cable, DVI cable, VGA cable, Optical fiber cable, USB Cable; Rca cable

Computer Cable, Hdmi Cable, Hdtv Cable, VGA cable, DVI cable

Audio/Video Cable, Video Cable, Pc Cable,

Data Transfer Cable, Data Cable, Digital Device Cable,

Hdmi Cable, Hdmi, Dvi Cable, Hdmi To Hdmi Cable, Hdmi-Hdmi Cable, Hdmi-Dvi Cable

Description

HDMI (High Definition Multimedia Interface) provides an interface between any HDMI-enabled audio/video source, such as HDTV, PS3, Blue Ray DVD players, XBox360 Elite, Home Theater, projector, Dish receivers and all other device with HDMI input. It transmits all ATSC HDTV standards and supports 8-channel digital audio, with bandwidth to spare to accommodate future enhancements and requirements.

Features:

HDMI 19 PIN male to HDMI 19 PIN male cable.

Double-color PVC moulding shell.

Certified HDMI 1.3b, back compliant with all previous HDMI versions, Support All HDMI Devices, transfers at 10.2 Gigabytes per second.

Supports 1080p Full HD picture quality and Supports up to 1600p (future proofed).

24K Gold plated connector for the best conductivity.

Use Oxygen free copper conductor to maximum signal transfer and minimize interference.

With Triple layer copper braided shielding to ensure lossless data transmission.

Buyer Selection

1. Gauge of cable: 30AWG, 28AWG, 26AWG or 24AWG.

2. Cable OD: 8.2MM, 7.3MM, 6.0MM, 5.5MM.

3. Cable length: 0.1M, 1M, 2M....20M

4. Ferrite rings for resisting EMI.

7. Shell Material: single-color PVC moulding, Double-color PVC moulding, Zinc alloy , Aluminum alloy.

8. Connector: Golden plated or Nickle plated

Similar Cable Available

VGA

HDMI / HDMI

DVI / VGA

DVI-D Single Link Cable

DVI-D Dual Link Cable

DVI-I Single Link Cable

DVI-I Dual Link Cable

DVI / HDMI

We can offer you various of Computer Connection Cable, including

Network RJ45 Cat5e, Cat6

Printer Cable (Convensional, IEEE1284)

Monitor Cable ( HDMI, DVI, SVGA, RCA, 3.5mm)

USB Cable (USB A / B, USB A M / F, USB A / Mini 5P)

Firewire IEEE1394 (4P, 6P)

Keyboard/Mouse Cable (DIN6, DIN8)

Modem Cable (DB9, DB15, DB25)

IDE Flat ATA / SATA

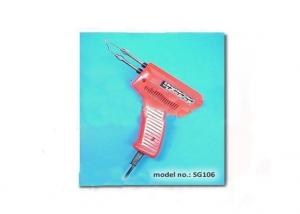

- Q: Where can I buy an electric iron?

- Electric irons are usually available at power tools stores and hardware stores.The electric iron comprises a soldering iron head, iron core, shell, wood handle, supply leads, plugs and other parts, is an indispensable tool for production of electronic and electrical maintenance, the main purpose is to welding components and lines, according to the mechanical structure can be divided into internal and external heating type electric iron electric iron, which is divided into no smoking tin soldering iron and tin suction type electric iron, according to different purposes is divided into large power and small power electric iron electric iron

- Q: When the circuit board is hot with the electric iron, some leather can not affect the work? Can you scrape the circuit board with a knife?

- Skin is no problem, as long as there is no broken copper does not affect the function, if the patent under the copper water clock out, there may be damp rust oxidation, if the conditions can make some green paint to prevent oxidation.

- Q: I have a 50 Watt electric iron. Can I solder the chips in my cell phone battery? What can 50 Watt electric irons be used for welding?

- Soldering the chip in the cell phone battery, the 50 Watt electric iron is too big, the 50 Watt electric iron is suitable for welding the big electronic component!

- Q: 0.5 new thick copper, iron soldering welding, how to live, to the Duodawa electric iron. Now the main iron is next to the copper, there is no temperature

- Such a large copper skin, it is estimated that no more than 100 can not welding

- Q: I can't solder it. It doesn't stick together. It keeps getting old. It rolls on it, but it doesn't stick

- First on the wire surface treatment, remove wire oxide, can make emery cloth polishing wire in welding thread shiny, then coated with flux (or rosin) easily welded.Aluminum core is not to toss about, definitely not an electric iron can be solved, you need special equipment.

- Q: What effect does the electric iron plug in and the electric iron head on the ground?

- On the floor after overheating, thermal expansion and contraction, the floor will be broken, the electric iron head without any problems, because the electric iron head temperature is rated.

- Q: Help me to the bathroom faucet close the holes. In dianlaotie how much W I have put the soldering file into the copper surface. But the welding cold touch off is not iron W number low. How much iron. Thank you

- 1. prepare can solder paste (solder paste is acidic), the actual use of only a little bit, a 300w-500w electric iron, 2. (a piece of tin solder wire with rosin can not be used, 3.) with a file in a file into a small hole tap around the copper surface, coated with solder paste, 4. heating after removal of iron, iron oxide skin on the head, put some solder paste on the head, the tin melt in the iron head, 5. heating tap (when necessary to prevent hot hole cloth, if there is a need to remove the leading plastic), continuous heating for a period of time not to leave, but also add some solder paste and when the temperature reaches 6. to solder, have been integrated, with the iron head office after leaving wipe soldering, 7. after cooling by iron sand paper cointegration can be.

- Q: I'm looking for an electric iron like a pair of pliers. Used to seal 10mm vials. The pliers head can be heated. Both sides can be heated at one end. This is to buy or need to make their own? If know to help me out of ideas? See if there's any other way It's a small bottle like eye drops. Seal the top. I do not know is the main production factory of eye drops. How do they seal it?.

- Electric tweezers, Taobao search!

- Q: How do you clean up the residue on the electric iron?

- The welding tip is necessary to leave the solder welding head protection.As for the smoke on the pipe, soak it with alcohol for 24 hours before wiping it.On the black part of the process can not be dealt with, things used for a long time, there will always be traces, and do not have to tangle with this.

- Q: How tin solder electric iron?

- Tin plated on a scraped lead. After the wire is dipped in the rosin solution, the hot iron tip with tin is pressed on the lead and the lead is turned. A thin layer of tin can be uniformly plated on the leads. Before the wire is welded, the insulating skin should be stripped off, and then treated by the above two items before welding. If multiple strands of wire wire, after polishing should be screwed together, and then tin.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DVI Cable

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Pieces pc

- Supply Capability:

- 800000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches