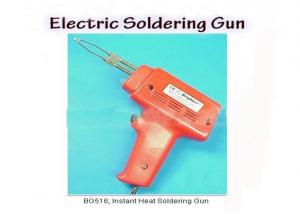

Electric Soldering Gun SG106

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Electric Soldering Gun, SG106

> Voltage: 110V or 220V

> Power: 100W,

> Cord: GB or A plug

> Packed in printed box

> Durable, Dependable

We are a direct manufacturer of electrical tools with experience of more than 25+ years. With our well experience and the stricted quality control, our company has become famous in many markets over the world.

Agents or distributors wanted. OEM is welcome!!

Our annual production quantity is two millions pieces for assorted models.

- Q: I have a 100 watt electric iron. Why can't it be plated with tin?. I want to weld the white iron plate, can I?

- One hundred watts can not weld white iron plate, the temperature is not high enough

- Q: Why isn't the electric iron hot? What's the reason for it? Can you fix it? How do you fix it?.

- What kind of electric iron are you using? It can be repaired. No fever, only the heater core is broken, or the battery is dead

- Q: 0.5 new thick copper, iron soldering welding, how to live, to the Duodawa electric iron. Now the main iron is next to the copper, there is no temperature

- You can heat it up with an alcohol lamp or a high powered hot air gun

- Q: Isn't it normal? It's all red

- The tip temperature is too high or the tip coating, and then burn would have severe oxidation and perforation, buy a nice tip, you can look at the green tip

- Q: Why is it so hard to weld? Instant welding is not firm, what should I do? What's the trick?

- Estimate that you are a novice, wire and copper bar is very good welding, said the method, but also try more, slowly understand, or else it can not be welded.1, the wire and copper strip welding surface polished bright.2, the rosin into powder, bubble point of alcohol, that is, rosin solution (yellow thick). Apply to wires and jump together. Or directly pour rosin powder in two places, slightly hot, melt on the line. This step is necessary, or it won't be welded.3, the copper strip and wire together. The iron head slightly against the copper wire, stretch into melted, saw smoke coming out, can take away the iron, 5, 6 seconds after the solder solidification is good. Remember to solder the wires around, so it's secure.4, welding wire better. With active welding wire.

- Q: Is electric iron an electric tool?

- It's a tool, but not an electric toolElectric iron is an electric heating tool,

- Q: Why doesn't the soldering iron touch the tin?

- It is OK to glue bit of colophony first, also can buy the silk that has colophony to use directly

- Q: I am a novice, in self-study scm. Want to do their own learning boards and power. But in the electronic circuit boards on the use of electronic components, what is the use of electric iron head? Is there anything else you need to use besides the electric iron? Want affordable.

- The pad of the pan is very big, besides, it is not necessary to do the exercises. It can use a few pieces of copper tilted head iron. Suggest a 20W and a 35W. The former is used to weld small components, and 35W is used to weld devices with greater heat dissipation. The two won't add up to ten dollars.With the proposed things to use public incense, do not recommend the use of solder paste, because it contains acidic substances, especially the SCM crystal oscillator is easy, and therefore can not start vibration, I have had this situation.To prevent overheating, there should also be a pointed forceps.Conditional word can also prepare the following things: with working lamp, magnifying glass or tin, tin suctioner with anhydrous alcohol (remove excess rosin).

- Q: The difference between the external and internal heat of the electric iron, the selection method and the selection of power

- External heating refers to the iron head in the heating core inside a kind of electric iron, also known as ordinary electric iron. Generally there are 30W, 40W, 60W, and so on. Welding of ordinary products, the temperature does not require any external hot electric iron.An electric iron with internal heating. The heating core is made of ceramic core. The heating core is inserted into the head of the iron. There is a single handle, there are welding platform. Heating faster than an external hot electric iron.There are many kinds and specifications of electric irons, and the sizes of welders are different. Therefore, the power and types of electric irons are reasonably chosen, which has a direct relationship with the improvement of welding quality and efficiency.

- Q: Can the electric iron of the school solder aluminium products?

- This problem should be like this if you want to belong to the welding of aluminum foil, aluminum and other small pieces of fine and thin pieces, can be used for welding or soldering iron, hot air gun, but low wire materials need to use M51 with M51-F welding flux, video can search "Weiouding copper and aluminum wire welding with welding" if is large, you need to use special WE53 liquefied gas as a heat source using porous spray gun

1. Manufacturer Overview

| Location | Kowloon, Hong Kong |

| Year Established | 1971 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electric Soldering Gun SG106

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords