Instant Heat Soldering Gun BG516

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

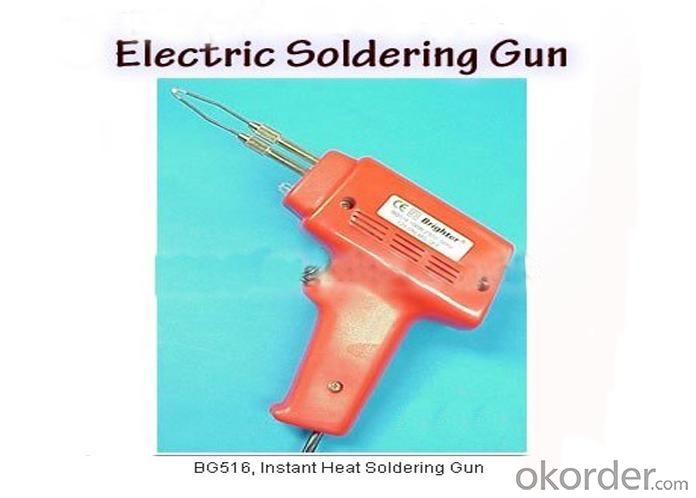

BG516, Instant Heat Soldering Gun

> Voltage: 110V or 220V

> Power: 100W,

> Cord: GB or A plug

> Packed in printed box

> Durable, Dependable

We are a direct manufacturer of electrical tools with experience of more than 25+ years. With our well experience and the stricted quality control, our company has become famous in many markets over the world.

Agents or distributors wanted. OEM is welcome!!

Our annual production quantity is two millions pieces for assorted models.

Instant Heat Soldering Gun

> Voltage: 110V or 220V

> Power: 100W,

> Cord: GB or A plug

> Packed in printed box

> Durable, Dependable

- Q: The electric iron can melt copper or aluminum? If the electric iron copper or aluminum soldering. It can weld copper or iron!

- They can not be melted. They have a high melting point. Copper is 1083.4 + 0.2 degrees, and aluminium is 660 degrees centigrade

- Q: Does electric iron need no rosin?

- Rosin is a soldering flux. See what you weld. If you solder gold fingers, you'd better paint it.

- Q: Who knows how to solder two coins together? Either the front or the side. I haven't solder it for days, thank you

- Coated with solder paste, welding can be, pay attention to use good solder paste, with high-power electric soldering iron, welding time a little longer, in fact, very easy to succeed, because I have welded

- Q: Why do solder always stay on the soldering iron instead of the circuit board when soldering it with a soldering iron?.

- No welding circuit board to smear a good welding flux is of good quality

- Q: What do you use as a fuse when using an electric iron?

- Electric soldering iron commonly used soldering agent, rosin and solder paste. The best choice of rosin, it is neutral and can increase the liquidity of solder, not corrosion circuit element and the tip; only use iron items such as solder paste only in welding hard tin, it can remove the metal oxide on the surface, has a certain resistance.

- Q: How do you clean up the residue on the electric iron?

- Electric heater with cotton can be removed!

- Q: What brand is desk electric iron best?

- Innovative high brand digital constant temperature welding table, CXG-80 quality is very good, it is very convenient to use

- Q: HAKKO 936 constant temperature electric iron temperature not constant, how should I do?

- The thermocouple is out of order

- Q: Can the electric iron of the school solder aluminium products?

- The welding of aluminium alloys with iron can be made in the case that the aluminum matrix must be very fine, or that aluminum is very thin film. But as long as there is a general aluminum structure and size of certain words, suggestion is to use liquefied petroleum gas porous WE53 special welding gun, and then with a low temperature aluminum welding.That is if you want to weld aluminum is aluminum foil, thin aluminum and other small and thin pieces, can be used for welding or soldering iron, hot air gun, but low wire materials need to use M51 with M51-F flux.Process for soldering electric iron1, the electric iron inserted into the electric heating.2. Adjust the pin of the capacitor and insert it into the printed circuit board3. Apply a small amount of solder paste on the contact between the capacitor pin and the circuit board.4. The iron head of the preheated electric iron is pressed at the contact point between the pin and the circuit board for a moment, so that the local temperature is increased to the melting point of tin wire. The solder wire to the pin contact with the iron head, when the appropriate amount of solder, solder wire removed along the pin element, remove the iron, solder joint into a round.5, diagonal pliers to cut unnecessary stitches, complete the soldering operation. Tip: right between the residence time and the operation steps of soldering a great influence on the welding quality, need to gradually learn in practice.

- Q: First iron...... Duoduosuosuo welding after the touch element, scared ~ I suspect this goods fast run...... Will it be broken?

- If it takes a long time, it will be bad.The simplest way is to hold the tube with a Tweezer (between the solder joint and the component), and when it is welded, the heat is transferred to the tweezers. This ensures that it will not overheat.

1. Manufacturer Overview

| Location | Kowloon, Hong Kong |

| Year Established | 1971 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Instant Heat Soldering Gun BG516

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords