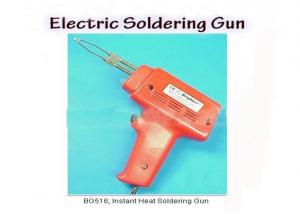

Instant Heat Soldering Gun BG511

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

BG511 Instant Heat Soldering Gun

Voltage: 110V or 220V

Power: 100W

Cord: GB or A plug

Packed in printed box

Durable, Dependable

We are a direct manufacturer of electrical tools with experience of more than 25+ years. With our well experience and the stricted quality control, our company has become famous in many markets over the world.

Agents or distributors wanted. OEM is welcome!!

Our annual production quantity is two millions pieces for assorted models.

- Q: I'm 40W thermoelectric iron, although can be defended, but not quite good-looking! What should the good welded USB interface and so on PCB!

- I am a solder manufacturer 0755-28105781, I QQ463641410 to use a little bit of tin wire, containing tin bright, at least to reach more than 50%. The higher the brightness of tin, the lower its melting point, the lower the content of tin, the higher the relative melting point, the effect of welding is not ideal, there will be false welding, tin is relatively slow, brightness, no amount of light.

- Q: Can electric irons weld brass?

- Brass requires special welding torch.

- Q: What about the power line of the electric iron being burned to a little?

- General electric iron is a dual core or three core cable if Tanghuai no exposed metal core wire inside so you can continue to use, if hot or deep so the exposed core wire with insulating tape and then wrapped the parting line. Or you can change the power cord directly

- Q: I often weld electronic componentsWill the electric iron of 30W sublimate the lead and its compounds in the solder into lead smoke? I often weld electronic components and worry about lead poisoning

- The key is the temperature of the electric iron, not the power.Can liquefy, will always be a little volatile.Not big, but there must be.

- Q: Help me to the bathroom faucet close the holes. In dianlaotie how much W I have put the soldering file into the copper surface. But the welding cold touch off is not iron W number low. How much iron. Thank you

- Buy a good brothers dip well and can touch something very practical

- Q: That kind of heating seat has 3 buttons and a switch on it. How can I get it?

- The simplest way is to find a multi stall ceiling fan switch, and then connect the electric iron electric wire. Can meet the requirements. There is also a way to use the power device to do it yourself, and then buy the existing thermostat thermostat iron.

- Q: I'm looking for an electric iron like a pair of pliers. Used to seal 10mm vials. The pliers head can be heated. Both sides can be heated at one end. This is to buy or need to make their own? If know to help me out of ideas? See if there's any other way It's a small bottle like eye drops. Seal the top. I do not know is the main production factory of eye drops. How do they seal it?.

- Electric tweezers, Taobao search!

- Q: Such as blade scraping, although to tin, but in a few hours with not occupied, and find solutions

- The temperature is too high, or a special iron head is damaged

- Q: What are the features and disadvantages of internal heating electric irons and external heating irons?

- Outside heat: iron head relatively thin, inserted in the middle of the iron. Internal heating type: the iron is small in size, and the iron head is wrapped with a soldering iron core.Internal heating type: relatively light, high efficiency, energy saving, disadvantages: the iron core is easier to burn out, and the service life is shorter.External heating: it is a traditional process with long service life. Disadvantages: compared with electricity, the volume is larger than that of internal heating.Such as welding ordinary circuit board, the internal heat type 10W or so can be, the outside heat type to 30W or so.

- Q: The soldering iron rack has several advantages to the electric iron

- The iron holder has no effect on the electric iron itself, mainly to the man who uses the iron. The great advantage is that you won't get burned.

1. Manufacturer Overview

| Location | Kowloon, Hong Kong |

| Year Established | 1971 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Instant Heat Soldering Gun BG511

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords