Supply European Plastic Window Frames Quality

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

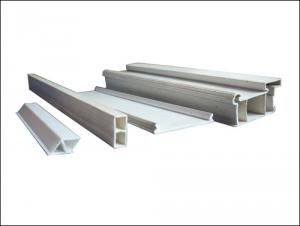

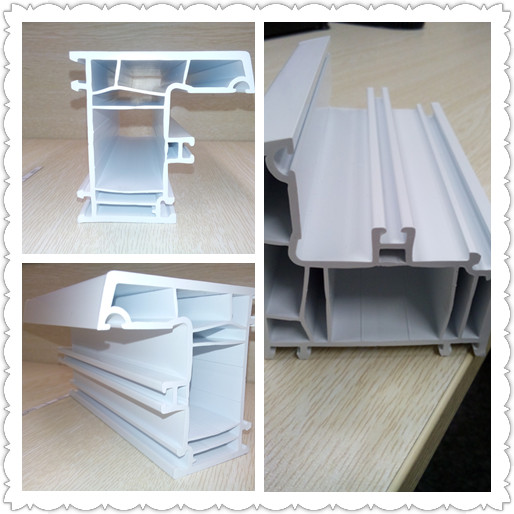

Pvc flat frame with assemble profile for window

1. Quick Details

2. Specifications

Attractive appearance

Simple and bright facades

High strength,good rigidity

Durable

Light and flexible open an close,

No noise Sealing well.

3. Packaging & Delivery

Packaging Details:

1)Packing in plastic bags and then as your requirement. 2)6m/piece length or customizable.

Loading: 20'GP about 10 tons

40'GP about 20 tons

40'HQ about 23 tons

Sample shipping. Sent out orders in 24 hours by TNT, DHL, EMS FedEx etc.

By air (DHL, FedEx, UPS, etc.)

By sea shipping when bulk order

A). Sample's lead time:1-2 days

B). 20'GP lead time: 5-8 days

40'GP lead time: 8-15 days

40'HQ lead time:10-15 days

- Q: Steel windows and aluminum windows compare which is more expensive

- Wind pressure strength and watertightness: Plastic windows due to the strength and rigidity of the material is low, although through the processing of steel to enhance, but its wind pressure and watertight performance than the aluminum window about two levels. Moreover, due to the steel window steel lining steel is not in its profile cavity angle into a complete frame system, window frame, fan four corners and T-shaped plastic welding angle strength is relatively low, according to the end of 1998 Shanghai enterprises inspection 425 Batch steel window three examples of the situation after the serious analysis of the "plastic window in the high - rise buildings should be used with caution.

- Q: PVC plastic profiles dip in the seam, how to deal with seamless docking

- Stabilizer too much or too little stabilizer is to inhibit the degradation, or with the release of hydrogen chloride reaction and to prevent the discoloration of PVC processing. Stabilizer according to the different types of different, but the total point, the amount of excessive will delay the material of the plasticization time so that the material export mold when the plastic is not, the formula system between the molecules are not fully dissolved, Its intermolecular structure is not strong cause. And the amount of too little will result in the formulation of relatively low molecular weight degradation or decomposition (also can be said to be plasticized), the stability of the intermolecular structure of the various components of the damage. So the amount of stabilizer will also affect the impact strength of the profile, too much or too little will cause the profile strength caused by the phenomenon of brittle profile.

- Q: China 's top ten brands of steel profiles in 2014

- 1. Conch Conch steel doors and windows profiles are Anhui Conch Group under a building materials business, Conch steel doors and windows is a national high-tech enterprises, is the top ten steel doors and windows brand ranking first. Conch Group in the country to build a branch. Conch Group is also a state-owned enterprise. But fake more 2. Shide in the steel doors and windows industry has a large Chinese market, it is controlled by the Dalian Shide Group. Northern market share is high but 14 years down the road. 3. Huaihai China Famous Brand. Domestic large-scale production enterprises in the few, specialized in the production of independent legal entities. National steel doors and windows one of the top ten brands, East China market share is high, favored by consumers. 4. Kemei Te Ke US special steel doors and windows is Sichuan Kemei Te Group's brand, its in Sichuan, Anhui, East China has a profile production base in the southwest region occupies a considerable market, favored by consumers.

- Q: Plastic steel window profile material

- GB 8814-2004 according to the thickness of the main section of the profile will be divided into three categories of ABC, according to the "visible wall thickness minimum / non-visible wall thickness minimum" said, A type of wall thickness of 2.8 / 2.5mm, B Type of material requirements wall thickness 2.5 / 2.0mm, C type of wall thickness does not specify the requirements. The mainstream of the national standard profiles are Class B.

- Q: What is the material of steel

- Plastic profiles are used for the production of doors and windows with PVC profiles, as early as the late 1950s has been in Germany, China began in 1983 from the beginning of the 20th century, the late 90s began universal application. Because simply use PVC profiles processing doors and windows strength is not enough, usually in the cavity to add steel to enhance the stability of doors and windows, so the profile of the steel interior made of plastic doors and windows are often called steel doors and windows. With the extensive use of steel doors and windows, PVC profiles for the production of steel doors and windows are commonly known as steel profiles.

- Q: The difference between steel and aluminum alloy profiles

- Aluminum doors and windows better, but I said that this aluminum alloy is not an ordinary aluminum alloy, its full name is called "heat insulation bridge aluminum" profile. This kind of aluminum alloy doors and windows profiles, it is more complex than ordinary old aluminum alloy structure, thickness and strength and finish much higher than the old aluminum alloy doors and windows profiles, his structural design more scientific and efficient for the family to save energy , With good insulation noise, cold insulation properties, not easy to deformation, discoloration, corrosion resistance and rugged than plastic steel profiles are several times higher. In the decoration of doors and windows, for steel windows and broken bridge aluminum alloy doors and windows of choice, broken bridge aluminum doors and windows of the cost is much higher than the steel doors and windows.

- Q: How plastic embossed profiles are made

- Plastic processing is a complex process, generally divided into the following main processing methods:

- Q: Plastic profile brittle extrusion process unreasonable reasons

- Excessive or insufficient material This is related to the process temperature setting and feeding ratio. The temperature setting is too high to cause the material to be plasticized. Some of the components with low molecular weight in the component will decompose and evaporate. The temperature is too low. Fully welded, the molecular structure is not strong, while the feed ratio is too large cause the material heating area and shear increases, the pressure increases, easily lead to plastic; feeding ratio is too small material heating area and shear reduction, Resulting in less plasticized, whether it is plastic or plastic surgery will cause plastic profiles crisp cutting collapse phenomenon.

- Q: What is the steel profile?

- GB 8814-2004 according to the thickness of the main section of the profile will be divided into three categories of ABC, according to the "visible wall thickness minimum / non-visible wall thickness minimum" said, A type of wall thickness of 2.8 / 2.5mm, B Type of material requirements wall thickness 2.5 / 2.0mm, C type of wall thickness does not specify the requirements. The mainstream of the national standard profiles are Class B.

- Q: What belongs to plastic profiles

- Plastic profile additives four: processing aids Auxiliaries are mainly developed to improve the performance of plastic molding. Plastic profile processing temperature and decomposition temperature is close, poor mobility, easy to stick in the equipment on the coking, so the production of plastic profiles need to add a certain amount of processing aids to overcome the defects of plastic profiles themselves. Plastic profile additive five: light stabilizer The light stabilizer can inhibit the photooxidation degradation reaction of the polymer by shielding and absorbing ultraviolet rays, quenching and exciting energy to capture free radicals, so as to give the products a good light stabilizing effect and prolong their service life. Plastic profile additives six: filler The filler is a solid additive that is different in composition and structure from plastic, also known as fillers. To improve the physical and mechanical properties of plastic and reduce the cost of plastic has a significant effect and economic value. Plastic profile production formula to add filler, plastic profiles can be heated after the size of the change in the rate of change, increased impact strength, increased rigidity, while also reducing production costs.

Send your message to us

Supply European Plastic Window Frames Quality

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords