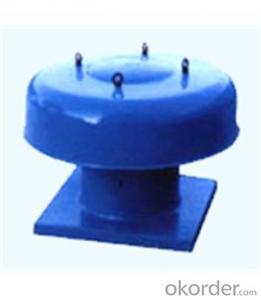

FRP axial fans

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Axial fan is a national committee to promote the use of a mechanical efficiency low-pressure ventilator, the aircraft low power consumption, low noise, and has excellent corrosion resistance and other characteristics. Can be used as industrial plant, machinery manufacturing, chemical industry, printing and dyeing, electroplating, pharmaceutical and other industries; theaters, hotels, office buildings, residential and other buildings. If wind shell removed. Also for their fan, but also in a longer exhaust pipe, installed in series interval, and to increase the total pressure of the pipeline.

(B) Fan Type:

T35-type axial fan impeller diameter divided according to the size NO2.8, NO3.15, NO3.55, NO4, NO4.5, NO5, NO5.6, NO6.3, NO7.1, NO8, NO9, NO10 , NO11.2 thirteen machine number, number of leaves of each machine number are for four. Leaves can be loaded into a 15 °, 20 °, 25 °, 30 °, 35 ° five kinds of angles. Therefore, since the size of each machine number of the blade installation angle, rotating speed of the spindle is different from the fan air pressure, air volume, and power consumption is not the same. (See performance table specific performance)

Transmission: selection of each pole motor with impeller directly coupled, the body shell made of a cylindrical shape, the direction of rotation is clockwise (viewed from the motor direction).

Fan selection table (performance table)

T35-type axial fan performance and choice of performance tables, refers to the standard conditions (temperature of 20, 50% relative humidity, atmospheric pressure 760 mm Hg, gas specific gravity 1.2 kg / m3) of air performance. When the rotor speed is changed, the fan can be converted following formulas:

Axial Fan Maintenance

1, the fan should be carefully checked before installing it because of packaging, transportation and damage, deformation, can be repaired properly after installation. The installation should pay attention to check the availability of loose coupling portion, blade and duct clearance should be uniform, not collide.

2, connecting the outlet of the pipe weight should not be borne by the fan duct, the installation should additional support.

3, in the axial fan air inlet end device must be installed set and installed protective barbed wire.

4, the fan base engaged with the ground plane must naturally not be forced to beat a bolt connection, to prevent deformation of the base. When you install the application level gauge calibration base, padded in order to maintain its horizontal position, and then tighten the bolt facilities.

5, the axial fan hoisting allowed to use, after installing wire transfer must first trial.

6, after a long time fan of unused, re-use, you must first check whether the prison because each coupling portion and reliable, and after the test run before the official use.

7, after the formal operation of the fan, once a year to check for loose screws, wires epidermis is damaged, repaired according to their specific circumstances.

8, always pay attention to the fan is in operation without abnormal noise, vibration is increasing, and timely inspection repair.

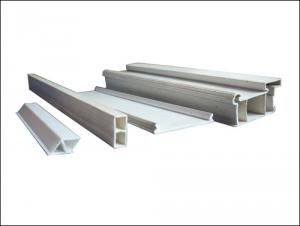

- Q: The development of steel profiles

- From the European to the American: European-style profiles are the mainstream of the market, but the rapid development of American profiles, which is due to some exports to the United States of steel-steel production enterprises driven by the United States as a lively, beautiful, delicate structure, delicate lines, Decorative, high light rate, high perspective, etc., has won the favor of consumers.As European-style profiles in China has 20 years of history, the US profile short-term can not replace the European profile in China's position. European-style profile is concerned about the fan package box, and the American profile is a box fan. Domestic steel doors and windows are basically fan package box.

- Q: Will the model of steel profiles (such as 88-type extrusion profiles, 80 extrusion profiles) is based on what to develop ah

- Strictly speaking, refers to the width of the bottom of the window frame profile. 88 is that the bottom of the frame width of 88 mm. And some profiles are not absolutely accurate, take the approximate value

- Q: Plastic doors and windows and plastic windows do not like?

- Glass fiber reinforced plastic (FRP) doors and windows 1) abroad to alkali-free glass fiber reinforced, the product surface finish is better, no need to deal with the system can be used directly to the window. Domestic self-developed glass fiber reinforced plastic doors and windows profiles generally with alkali glass fiber reinforced, the surface of the profile after grinding, available electrostatic powder coating, surface coating and other technical processes, access to a variety of colors or texture of the decorative effect. The following are the same as the " 2) Do not use high-alkali glass fiber made of profiles. The following are the same as the " 3) FRP doors and windows profiles have a high longitudinal strength, under normal circumstances, you can not enhance the steel. But the doors and windows size is too large or high wind pressure requirements, should be based on the use of requirements to determine the enhanced approach. The transverse strength of the profile is low. Fiberglass doors and windows frame for the assembly of the turret, the joints need to use sealant seal to prevent leakage of the gap.

- Q: Is not aluminum alloy better than steel?

- Plastic shortcomings: Each product has its shortcomings, with the extensive use of steel profiles, some shortcomings also will be exposed. China's steel profiles most of the poor quality of the use of lead salt stabilizer, finished lead content between 0.6% -1.2%. Lead is a harmful substance to the human body, when the poor quality of aging, will precipitate lead dust, long-term exposure will lead to excessive lead in the blood, and even lead poisoning. The recent introduction of calcium and zinc and organic tin solution to solve the product contains Lead problems, but because of price reasons and technology immature, there is no large-scale application.

- Q: Fence material outside the plastic inside is iron or steel this material called

- Plastic steel profiles are made of polyvinyl chloride (PVC) resin as the main raw material, plus a certain proportion of stabilizers, colorants, fillers, UV absorbers, etc., by extrusion of the profile.

- Q: What is the material of steel

- Plastic profiles are used for the production of doors and windows with PVC profiles, as early as the late 1950s has been in Germany, China began in 1983 from the beginning of the 20th century, the late 90s began universal application. Because simply use PVC profiles processing doors and windows strength is not enough, usually in the cavity to add steel to enhance the stability of doors and windows, so the profile of the steel interior made of plastic doors and windows are often called steel doors and windows. With the extensive use of steel doors and windows, PVC profiles for the production of steel doors and windows are commonly known as steel profiles.

- Q: Plastic profile brittle extrusion process unreasonable reasons

- Excessive or insufficient material This is related to the process temperature setting and feeding ratio. The temperature setting is too high to cause the material to be plasticized. Some of the components with low molecular weight in the component will decompose and evaporate. The temperature is too low. Fully welded, the molecular structure is not strong, while the feed ratio is too large cause the material heating area and shear increases, the pressure increases, easily lead to plastic; feeding ratio is too small material heating area and shear reduction, Resulting in less plasticized, whether it is plastic or plastic surgery will cause plastic profiles crisp cutting collapse phenomenon.

- Q: What belongs to plastic profiles

- Plastic profiles are used more: window frames, staircase handrails, troughs, wall feet, shaped tubes and so on. Raw materials are mainly hard PVC, a few are semi-hard PVC, soft PVC, polyurethane low foam and other materials. Plastic profiles with its excellent thermal insulation performance is listed as one of China's key development of building materials. In the production of plastic profiles, the need to pay attention to what problems in order to ensure the quality of profiles and technology.

- Q: What is the difference between plastic doors and windows and steel doors and windows?

- Through the cutting, welding, etc. made of doors and windows of the frame fan, equipped with sealing tape, tops, hardware and other accessories made of doors and windows, in order to enhance the rigidity of the profile, more than a certain length of the cavity need to add reinforced steel (steel Lining), this kind of doors and windows called plastic doors and windows.

- Q: The main features of steel profiles

- Plastic steel profile referred to as steel, the main chemical composition is PVC, it is also called PVC profiles. Is widely used as a new type of building materials, because of its physical properties such as rigidity, flexibility, corrosion resistance, excellent anti-aging properties, is usually used as copper, zinc, aluminum and other non-ferrous metals excellent substitutes.

Send your message to us

FRP axial fans

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords