FRP grating, grating cover

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

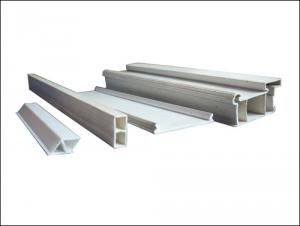

FRP grating:

FRP grating is made of a glass fiber reinforced materials, unsaturated polyester resin as the matrix, through special processing composite made of a plate-like material with a lot of space, it can be used as a structural material, used as a corrosion environment floor, trench cover, platform, ship decks, stairs, plank and so on.

Grille through a glass fiber braided, resin cast integrally molded together, making the distribution of many of the rules with a rectangular, square spaces FRP grid plate, with two-way mechanical characteristics of the same sex. It can be widely used in petroleum, chemical electronics, electricity, paper, printing and dyeing, electroplating, marine exploration, sewage treatment and other industries working platforms, equipment platforms, drilling platforms, walkways, etc., are ideal for corrosive environments, but also applies to civil construction on facilities.

FRP grating has a long life, low cost, safe, reliable, maintenance-free, as well as beautiful series of advantages. Has been promoting the use of such products in the United States thirty years, FRP grating production and use of sales have been standardized, serialized, the commercialization, the amount is quite large. In the Gulf region, the reconstruction of the Middle East oil fields, the experts, that the use of FRP grating is the most economical and reasonable material, which is being heavily used. FRP grating is also being used in Asia, Singapore, Taiwan and other regions.

Actual size according to customer needs, can be cut stitching. Use stainless steel grille snaps between the glass plates require stitching connection.

FRP grating characteristics:

1 anti-corrosion: a very superior acid and alkali resistance, and many other organic solvents and salts gas, corrosive liquid medium can, in the field of preservation has incomparable superiority. According to the actual requirements of the case, can be selected and used phthalic economic type, isophthalic, vinyl type resin as the matrix material.

2 light weight, high strength, and easy to cut, the installation: the resin and because it is made of glass fiber composite with a density of not less than 2 kg per cubic centimeters, only a quarter of steel, aluminum 2 / 3. Its strength is 10 times of rigid PVC, aluminum and absolute intensity level than ordinary steel. Its light weight, can greatly reduce the base support, thereby reducing the material cost of the project. Its cut is easy to install, no flare and large lifting equipment, only a small amount of manual and electric tools, making the installation costs are greatly reduced.

3 anti-aging: life in more than 30 years.

4 flame: Common flame retardant grill flame propagation rate (ASTM E-84) does not exceed 25; flame retardant vinyl grill senior propagation rate does not exceed 10. Oxygen index of not less than 28 (GB 8924).

- Q: The development of steel profiles

- From white to color: color profiles change the steel doors and windows in the past monotonous white, with the building as a whole with the perfect color. Color profiles market share rose rapidly, especially in some high-end residential area widely used.

- Q: Steel windows and aluminum windows compare which is more expensive

- Wind pressure strength and watertightness: Plastic windows due to the strength and rigidity of the material is low, although through the processing of steel to enhance, but its wind pressure and watertight performance than the aluminum window about two levels. Moreover, due to the steel window steel lining steel is not in its profile cavity angle into a complete frame system, window frame, fan four corners and T-shaped plastic welding angle strength is relatively low, according to the end of 1998 Shanghai enterprises inspection 425 Batch steel window three examples of the situation after the serious analysis of the "plastic window in the high - rise buildings should be used with caution.

- Q: Is not aluminum alloy better than steel?

- Aluminum alloy usually use copper, zinc, manganese, silicon, magnesium and other alloy elements, the early 20th century by the German Alfred Wilm invention, the development of the aircraft to help greatly, after a World War II German aluminum alloy composition is classified as state secrets. Compared with ordinary carbon steel has a lighter and corrosion-resistant performance, but the corrosion resistance is not as pure aluminum. In the clean, dry environment, the surface of aluminum alloy will form a protective oxide layer.

- Q: Fence material outside the plastic inside is iron or steel this material called

- Ordinary steel profiles will be deformed, the color is relatively monotonous, usually white, if you want to change the color will add PVC with the film, a long time the PVC film will fade. Automotive supplies industry in the use of steel, the material requirements are relatively high, the most typical is the engine chassis protection board, has been widely used by most riders. Plastic steel is also used in the production of tapered roller bearing cage. Plastic cage has: 1, reduce the friction and roller slip, reduce the working temperature; 2, improve safety and performance; 3, fail safe mode, not stuck.

- Q: How many meters of a conch plastic steel profile

- You ask what is the use, to do is to open the window or push and pull, and generally 6 meters large amount of work can go to the factory to ask them how long pull

- Q: Specification for steel profiles

- Before 50, did not use 40 or 38, 10 years ago I have done spliced steel, and now who is willing to splicing ah. But really want to splice, and now have steel can also be spliced.

- Q: Plastic profile brittle extrusion process unreasonable reasons

- Excessive or insufficient material This is related to the process temperature setting and feeding ratio. The temperature setting is too high to cause the material to be plasticized. Some of the components with low molecular weight in the component will decompose and evaporate. The temperature is too low. Fully welded, the molecular structure is not strong, while the feed ratio is too large cause the material heating area and shear increases, the pressure increases, easily lead to plastic; feeding ratio is too small material heating area and shear reduction, Resulting in less plasticized, whether it is plastic or plastic surgery will cause plastic profiles crisp cutting collapse phenomenon.

- Q: Plastic steel window profile specifications models which

- Plastic doors and windows are made of polyvinyl chloride (PolyVinyl Chloride, often referred to as PVC) resin as the main raw material, plus a certain percentage of stabilizers, colorants, fillers, UV absorbers, etc., by extrusion molding, and then Through the cutting, welding or screw way made of doors and windows frame fan, equipped with sealing tape, tops, hardware, etc., at the same time to enhance the rigidity of the profile, more than a certain length of the cavity needs to fill the steel lining Tendons), so made of portal windows, called steel doors and windows.

- Q: What is the broken bridge of aluminum? What are the characteristics?

- Waterproof, fireproof, anti-theft performance: broken bridge aluminum doors and windows with a rainwater structure designed to completely separate the rain from the outdoor, watertight in line with national standards; its aluminum alloy material for the metal material, Can be a good solution to the family fire hazard; for anti-theft performance is good, because the broken bridge aluminum composite window prepared a good hardware accessories and senior decorative locks, thieves face it can only helpless.

- Q: Bathroom plastic door with what material to do

- Glass fiber reinforced plastic (FRP) doors and windows 1) abroad to alkali-free glass fiber reinforced, the product surface finish is better, no need to deal with the system can be used directly to the window. Domestic self-developed glass fiber reinforced plastic doors and windows profiles generally with alkali glass fiber reinforced, the surface of the profile after grinding, available electrostatic powder coating, surface coating and other technical processes, access to a variety of colors or texture of the decorative effect. 2) Do not use high-alkali glass fiber made of profiles. 3) FRP doors and windows profiles have a high longitudinal strength, under normal circumstances, you can not enhance the steel. But the doors and windows size is too large or high wind pressure requirements, should be based on the use of requirements to determine the enhanced approach. The transverse strength of the profile is low. Fiberglass doors and windows frame for the assembly of the turret, the joints need to use sealant seal to prevent leakage of the gap.

Send your message to us

FRP grating, grating cover

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords