PVC UPVC Profile , Window and Door Frame Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 100 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

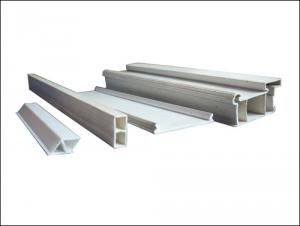

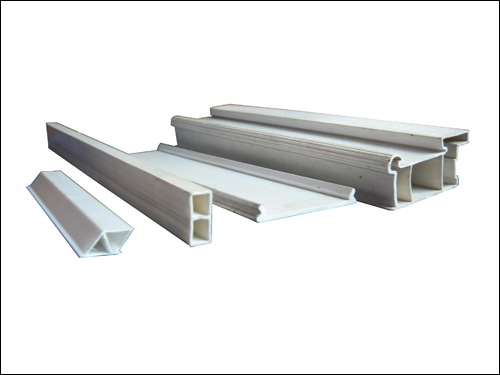

1. Product Description for PVC UPVC Profile and Frame

A casement window is hinged at the side and opens outward. It provides excellent ventilation,at times literally reaching out and catching the breeze. It looks like a narrow picture window because, unlike double hung or sliding windows, it has no rail to obstruct the view.

Some casement windows are simply pushed open, but most have a hand crank. Screens are placed on the inside of the window, where they're more protected from the elements. If you're installing windows over a sink, countertop or appliance, a casement window with a crank can be the perfect solution.

One of the things to look for in a casement window is how far it opens. The best open up perfectly perpendicular to the house for maximum ventilation

They are opened with a crank, lever, or cam handle, which is placed around hand height or at the bottom and serves as a window lock.

A crank, stay, or friction hinge is necessary when the window opens outward, to hold the window in position despite wind.

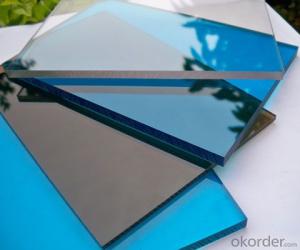

Often the glass panes are set in a rabbeted frame and sealed with beveled putty or glazing compound to secure the glass.

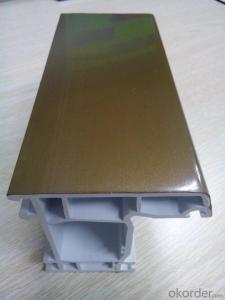

2. Photo for PVc UPVC Profile and Frame

- Q: Will the model of steel profiles (such as 88-type extrusion profiles, 80 extrusion profiles) is based on what to develop ah

- The so-called 88,80,60, refers to the bottom of the profile width. The unit is millimeter. The profile manufacturers have these specifications are refers to the bottom of the width is the same, but different manufacturers of profile height is not exactly the same.

- Q: Steel windows and aluminum windows compare which is more expensive

- Air tightness: Plastic window due to the box, fan components are welded, so the air tightness should be slightly better than the spiral of the aluminum alloy window, but the aluminum window profile height accuracy, box, fan with more closely, so the two are still in a Level level. 3, the insulation performance: aluminum window insulation performance as plastic window is good, but the ratio of the two window heat transfer ratio is only 1.36 times (single window) and 1.44 times (single frame double glass).

- Q: PVC plastic profiles dip in the seam, how to deal with seamless docking

- Stabilizer too much or too little stabilizer is to inhibit the degradation, or with the release of hydrogen chloride reaction and to prevent the discoloration of PVC processing. Stabilizer according to the different types of different, but the total point, the amount of excessive will delay the material of the plasticization time so that the material export mold when the plastic is not, the formula system between the molecules are not fully dissolved, Its intermolecular structure is not strong cause. And the amount of too little will result in the formulation of relatively low molecular weight degradation or decomposition (also can be said to be plasticized), the stability of the intermolecular structure of the various components of the damage. So the amount of stabilizer will also affect the impact strength of the profile, too much or too little will cause the profile strength caused by the phenomenon of brittle profile.

- Q: Plastic steel window profile material

- I do not know upstairs two self-proclaimed expert, in the line and do so long. According to the national market, the top three domestic brands is nothing but Shide, Conch, Finance, three years ago I work in Shide, and now I work in the financial. I do not know the landlord said the profile of the brand, but the beginning of this year Shide new 7 sealed series did in the building materials city speculation to the two hundred and seventy-eight. If the landlord said the profile is not this, then the 280 price is high and understandable. In addition to the grade of the profile is this argument, GB 8814-2004 according to the thickness of the main profile of the profile will be divided into three categories of ABC, according to the "visible wall thickness minimum / non-visible wall thickness minimum" A type of material requirements wall thickness 2.8 / 2.5mm, B type requirements of wall thickness 2.5 / 2.0mm, C type of wall thickness does not specify the requirements. The mainstream of the national standard profiles are Class B. In addition, I answered the second floor of the problem, Jinpeng profiles according to the national market is also a good profile, ranked fourth in the current controversy is not large.

- Q: What is the material of steel

- Plastic profiles are used for the production of doors and windows with PVC profiles, as early as the late 1950s has been in Germany, China began in 1983 from the beginning of the 20th century, the late 90s began universal application. Because simply use PVC profiles processing doors and windows strength is not enough, usually in the cavity to add steel to enhance the stability of doors and windows, so the profile of the steel interior made of plastic doors and windows are often called steel doors and windows. With the extensive use of steel doors and windows, PVC profiles for the production of steel doors and windows are commonly known as steel profiles.

- Q: The difference between steel and aluminum alloy profiles

- Plastic windows are easy to weather, aluminum alloy will not. If you want to be insulated when you do windows with double glass

- Q: Plastic profile brittle extrusion process unreasonable reasons

- The low molecular weight of the product is not discharged There are two general approaches to the production of low molecular weight components in the product, one at the time of hot blending, which can be vented through the dehumidification and exhaust system during hot blending, partly by partial residual and extruded heat Water and hydrogen chloride gas. This is usually through the host exhaust section of the forced exhaust system to force the discharge, the vacuum is generally between -0.05Mpa-0.08Mpa, not open or too low, will remain in the product of low molecular weight, Resulting in mechanical properties of plastic profiles decreased, resulting in plastic profiles crisp.

- Q: Plastic doors and windows and plastic doors and windows have anything to do

- According to the characteristics of profiles, the profiles are roughly divided into European and American two. European doors and windows of its characteristics are: profile formulations still use the traditional lead salt heat stabilizer, a small number of countries and enterprises began to use environmentally friendly organic tin heat stabilizer; main section of the profile profile is generally designed for three or four main chamber, The total number of chambers to 6 to 8, wall thickness is generally 2.5 ~ 3.0mm. Doors and windows with fan-fan frame structure, fan section larger, with pulley, can be removed; built-in glass, dry mosaic; window open in the foreign under the hanging window-based, a small amount of sliding window.

- Q: What is the broken bridge of aluminum? What are the characteristics?

- Waterproof, fireproof, anti-theft performance: broken bridge aluminum doors and windows with a rainwater structure designed to completely separate the rain from the outdoor, watertight in line with national standards; its aluminum alloy material for the metal material, Can be a good solution to the family fire hazard; for anti-theft performance is good, because the broken bridge aluminum composite window prepared a good hardware accessories and senior decorative locks, thieves face it can only helpless.

- Q: Plastic doors and windows profiles

- The overall quality of plastic doors and windows by the quality of hardware accessories and installation of a great impact, because the domestic enterprises PVC plastic doors and windows profile profile shape and size are not the same, hardware accessories can not be unified, so the production of each variety of parts Can not be large, it is difficult to form a scale effect, in addition, due to the overall level of consumption of domestic doors and windows is still very low, limiting the price of PVC plastic doors and windows, PVC plastic doors and windows hardware accessories prices are too low, causing manufacturers to meet the market had to reduce Cost and make cheaper cheap hardware accessories. Fortunately, the new standards for plastic window hardware is being developed, hoping to standardize the hardware market. Excellent hardware accessories, can improve the overall performance of the window, such as flat window using multi-point locking than a single point of locking the sealing and wind pressure performance is much higher, the use of corner hinge or adjustable hinge its performance It is much stronger than ordinary type or saddle type hinge, it can effectively prevent fan sagging phenomenon. In addition, the use of silicified and the middle of the taps with the top of the top coat is much higher than the ordinary.

Send your message to us

PVC UPVC Profile , Window and Door Frame Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 100 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords