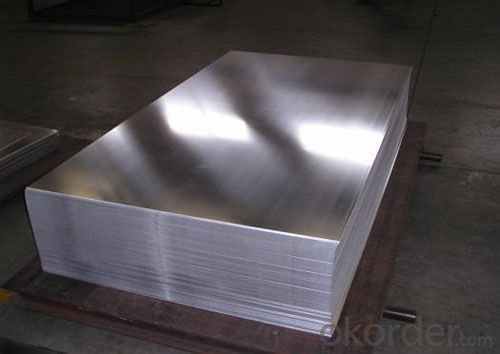

Supplier 1050 O Aluminum Sheet For Roof Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 g/m²

- Supply Capability:

- 200000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Supplier 1050 O Aluminum Sheet For Roof Sheets

Main Specification | |

Alloy | AA1*** (AA1050, 1060, 1070, 1085, 1100 and etc.) |

AA2*** (AA2014, 2017, 2019, 2024 and etc.) | |

AA3*** (AA3003, 3004, 3005, 3104 and etc.) | |

AA5*** (AA5005, 5052, 5082, 5083, 5182 and etc.) | |

AA6*** (AA6061, 6082 and etc.) | |

AA7*** (AA7050, 7075, 7475 and etc.) | |

AA8*** (AA8011) | |

Temper | O; H112, H14, H16, H18, H22; T3, T4, T6, T351, T451, T651 and etc. |

Thickness | 0.15-450mm |

Width | 300-3000mm |

Length | 500- 12000mm |

Standard | GB/T 3198-2006 |

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will b.e sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union,etc

- Q: 3D MAX must set motion for each object. Is there a 3D mechanical design software that can simulate the mechanical movement of the parts?As long as the specified object is motor, coupling, chain, gear, into the simulation, the three-dimensional map of the motor shaft will rotate, and drives the coupling, keys, gear for the corresponding movement, rather like 3D Max that is the true state of motion to each object design movement performance of this machine combination?

- SOLIDWORKSBut it is also necessary to develop the law of motion relative to 3DMAX, but your modeling is a problem,Can you NURBS? SOLIDWORKS does not support polygon modelingIf I import the file, there's only line segments. I haven't found a better wayIt's better to continue using 3DMAX

- Q: What are the basic requirements for the design of mechanical parts?

- 2. stiffnessThe elastic deformation of a component at work does not exceed the allowable limit. This is called the stiffness requirement. Obviously, only when the elastic deformation is too large to affect the working performance of the machine, it is necessary to meet this requirement. For this kind of parts, besides the strength calculation, the stiffness calculation must be done.

- Q: Force calculation is in the component diagram, the size of the component is obtained by force, and if you don't draw the parts first, how do you draw the general plan?How do you calculate the force of a part if you draw the part diagram first and don't know the size relation between the parts?

- First draw a diagram, determine the location of each part, then draw the parts drawing, and finally the general drawing

- Q: What are the key factors in designing mechanical parts?

- 2- rationality. Also to the shaft, for example, the outer diameter tolerance depends on what things, such as with bearings, it must be in accordance with the requirements of the base hole design, that is, in accordance with the diameter tolerance of bearings to determine the diameter tolerance.

- Q: Where are the machine parts designed to be finished?

- To the mechanical processing plant ah, there are many machinery processing plants are based on the processing of parts to others to survive, and our products are parts of those machinery factory processing

- Q: I'm going to learn 3D design. I used to just CAD.Excuse me, is it good to learn PRO-E or SOLIDWORK?I mainly used in product design (such as sheet metal parts, machining parts and plastic parts, etc.) is used to design the mould.Also, you can download the best Chinese version of these two software from the Internet, please ask friends about the locationUrgently...

- These two can, there is a director, according to the domestic general situation, usually PROE use more, exchange more convenient, as long as there is a three-dimensional software with skilled, no matter that can be.

- Q: Why do the design of mechanical parts (flanges and elbows) be based on the yield limit?

- When the metal material reaches its yield limit, the plastic deformation still goes on without increasing the external force. The general mechanical parts (flanges, elbows) and engineering structural parts are not allowed to produce plastic deformation, otherwise it will fail and accidents. Therefore, the design of mechanical parts (flanges and elbows) mostly takes the yield limit as the design.

- Q: I would like to open a small mechanical design company (specializing in the design of mechanical parts, etc.) can you make money?

- I really heard about this kind of company. Key: business promotion, design experience, additional experience.If you can get enough money, if you open the advertising skills and experience in mechanical design, powerful enough if you can tell the customer to design the end where I can get a good and where can I find a cheap and can ensure the processing precision and efficiency of the manufacturers, do it.On the contrary, think twice!

- Q: I am a bachelor degree in industrial design and have been sitting here for two months now, 20The feeling is still not understand, not figure painting, other colleagues are busy, I could not ask, do not know how to do, give me a leading figure today, let me figure it out on my own, I draw more and more have no confidence, I do not know because many mechanical components, do not know how to do.. Tired ~ ~ mechanical aspects of the great God, I pointed to the Ming road! Thanks

- Do not understand to communicate with people ah ~ you can truthfully and under the leadership of the reaction, find a master under guidanceA mechanical design is learning by doing, the school learned to pick it up, in addition to learn how to use the design manual, design experience for reference to others

- Q: Before listening to the teacher mentioned that, when the design of components, we should take into account the actual processing capacity of the factory, and some look very simple things, the factory is unable to process! I want to know what the reason is!!!

- There should be a lot of things. For example, the processing capacity of the equipment is only 1000mm, and the things you design have 1100mm, so the existing equipment can not be processed. For example, the surface roughness you require is Ra0.2, and the machining accuracy of your equipment can only be Ra0.8. That's more than the processing capacity of the equipment. And some things are processing problems, for example, you design things outside the small hole, there is a big hole inside, your device does not have this function.Think of these kinds of things for the time being.

Send your message to us

Supplier 1050 O Aluminum Sheet For Roof Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 g/m²

- Supply Capability:

- 200000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords