Steel supply company offer cheap construction material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 56734 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold rolled sheet steel products are used in a wide variety of end applications such as appliances, automobiles - exposed as

well as unexposed parts, electric motors, plumbing fixtures, drum manufacturing, shelving, furniture, doors, toolboxes, tubing

products, unexposed construction products, as well as many other areas of manufacturing.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

Packing:

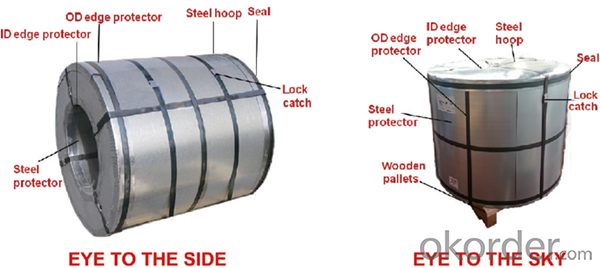

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will

provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing

as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: For some reason, if you rub iron oxide or lodestone (both very crumbly, dark, mineral-like materials) into soft, unhardened steel, their particles actually get stuck into the surface of the steel (that is, darkening it). My question is, how does this work? How come iron oxide and lodestone can get stuck, and how come other materials (like silicone carbide, for example) do not?My second question is, are there any materials that can get stuck into steel, that is also blue in color, and how would I best obtain it?

- Funny! 100!

- Q: What is the maximum width of steel coils?

- The maximum width of steel coils can vary depending on various factors such as the type of steel, manufacturing capabilities, and intended use. However, in general, steel coils typically have a maximum width of around 2,200 millimeters or 86.6 inches. This width is commonly used in the steel industry for standard-sized coils. It is important to note that specialized steel coils or custom manufacturing processes may allow for wider widths, but these would be less common and may require specific equipment or processes.

- Q: I have a carbon steel file that I want to bend in a letter C shape. So, what is the malliable temperature? If it's low, could it be done in a camp fire?

- It's now not rather that rough. You can use your charcoal grill to do it. First construct a colossal fireplace in it after which bury the metal within the coals. It'll simplest take approximately ten minuites or so for the metal to warmth by way of. Then decide on it out of the coals with tongs and drop it right into a bucket of water. Repeat as preferred. Eventually it is going to get as brittle as glass. To repair this, you have got to anneal the steel. Again warmth the steel within the coals, simplest this time allow it keep there till the coals cross the entire manner out all by way of themselves. Next day while the entire manner cool, Take it out and blank it off. Viola!, you may have hardened metal.

- Q: What are the different methods of coil blanking for irregular shapes?

- There are several methods of coil blanking for irregular shapes. One common method is laser blanking, which uses a high-powered laser to cut the shape directly from the coil. This method is highly precise and allows for complex shapes to be cut with minimal waste. Another method is water jet blanking, which uses a high-pressure stream of water mixed with abrasive particles to cut the shape from the coil. Water jet blanking is often used for thicker materials or when the material being cut is sensitive to heat. Additionally, there is also die blanking, which involves the use of a die to stamp the shape out of the coil. This method is commonly used for larger production runs and can be automated for increased efficiency. Lastly, there is also plasma blanking, which uses a plasma torch to cut the shape from the coil. Plasma blanking is often used for thicker materials or when high cutting speeds are required. Overall, the choice of method for coil blanking irregular shapes depends on factors such as material thickness, shape complexity, production volume, and desired precision. Each method has its advantages and limitations, and selecting the most suitable method is crucial for achieving optimal results.

- Q: How are steel coils used in construction?

- Steel coils are commonly used in construction for a variety of purposes, such as forming the structural framework of buildings, manufacturing steel beams, and reinforcing concrete structures. The coils are unraveled and shaped into different forms, allowing them to provide strength, stability, and durability to the construction projects.

- Q: What are the common uses of pre-painted steel coils?

- Pre-painted steel coils are commonly used in various industries such as construction, automotive, and appliance manufacturing. They are primarily utilized for exterior and interior building applications, including roofing, siding, and wall panels. Additionally, pre-painted steel coils find extensive usage in producing automotive parts, such as body panels and structural components. The coils are also employed in the manufacturing of appliances like refrigerators, ovens, and washing machines, providing a durable and aesthetically pleasing finish.

- Q: I want to buy a VERY sturdy bunkbed, but don't know which one would be better with not getting loose or falling apart.

- Metal/Steel. :)

- Q: What are the factors that affect the price of steel coils?

- There are several factors that influence the price of steel coils. Firstly, the cost of raw materials such as iron ore and coal, which are essential for steel production, can significantly impact the price. Additionally, the demand and supply dynamics of steel in the market play a crucial role. Factors like economic growth, construction activity, and infrastructure development can drive up the demand for steel, leading to price increases. On the other hand, if there is excess supply or reduced demand, prices may decrease. Moreover, fluctuations in energy costs, transportation expenses, and currency exchange rates can also affect the final price of steel coils.

- Q: How long does the coating on steel coils last?

- The longevity of the coating on steel coils depends on various factors such as the type of coating used, the environmental conditions it is exposed to, and the maintenance practices. However, on average, a well-applied coating can last anywhere from 10 to 20 years before requiring reapplication or maintenance.

- Q: How are steel coils used in the manufacturing of solar panels?

- Steel coils are used in the manufacturing of solar panels primarily for the structural support and durability they provide. These coils are often used to construct the frames and mounting systems that hold the solar panels in place. The strength of steel ensures that the panels remain stable and secure, even in harsh weather conditions. Additionally, steel coils can be shaped and formed to meet the specific design requirements of solar panel installations, making them a crucial component in the manufacturing process.

Send your message to us

Steel supply company offer cheap construction material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 56734 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords