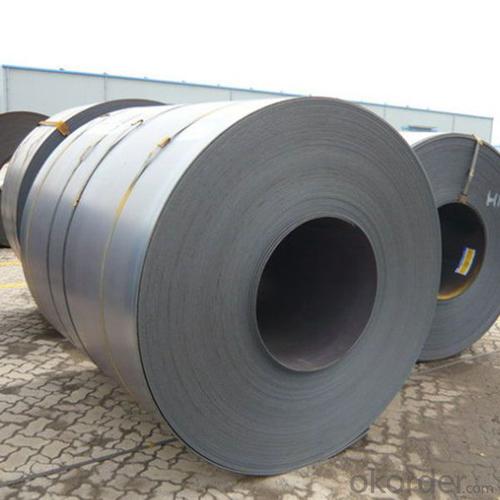

Steel Sheets,Steel Plates,Steel Coils from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 250000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

DETAILS:

Thickness | 0.5-100mm |

Width | 1250mm,1500mm,1800mm,2000mm.,2500mm or as required |

Length | 2000-12000mm |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | A36,SS400,SPCC,SPHC, Q195, Q 235,Q345 |

Tehnique | Hot rolled;cold rolled |

Payment | TT ,L/C |

Packing | Standard seaworthy packing or as required |

Market | Mild east, North/South America, Europe, Asia,Africa etc |

Certificate | BV,SGS,MTC |

Delivery time | 15-45days after confirming the order |

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

PAYMENT&DELIVERY FOR STEEL COILS/SHEETS

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

FEATURES OFSTEEL COILS

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ

Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

- Q: What is the maximum tension that steel coils can withstand during uncoiling?

- The maximum tension that steel coils can withstand during uncoiling depends on various factors such as the type and thickness of the steel, the diameter and width of the coil, and the specific application. However, in general, steel coils can typically withstand tensions ranging from a few hundred pounds to several thousand pounds. It is important to consult the manufacturer's specifications or conduct specific tests to determine the exact maximum tension for a particular steel coil.

- Q: What are the main factors that affect the corrosion resistance of steel coils?

- The main factors that affect the corrosion resistance of steel coils include the composition and purity of the steel, the presence of alloying elements, the surface condition and finish of the coils, the exposure to moisture and corrosive substances, and the protective coatings or treatments applied to the steel.

- Q: What are the different types of surface treatments for steel coils?

- There are several types of surface treatments for steel coils, including galvanizing, painting, and coating. Galvanizing involves applying a layer of zinc to protect the steel from corrosion. Painting involves applying a layer of paint to provide both corrosion resistance and aesthetic appeal. Coating involves applying a thin layer of protective material, such as polymer or epoxy, to enhance the steel's durability and resistance to corrosion. These surface treatments are chosen based on the specific requirements of the steel coils and the desired end-use applications.

- Q: Can steel coils be coated with nickel?

- Yes, steel coils can be coated with nickel.

- Q: What are the common coil packaging materials?

- The common coil packaging materials include stretch film, shrink wrap, steel strapping, and wooden or cardboard cradles.

- Q: What are the standard dimensions and weights of steel coils?

- The standard dimensions and weights of steel coils can vary depending on the specific type of steel and its intended use. However, some common dimensions include coil widths ranging from 600mm to 2000mm, coil outer diameters ranging from 800mm to 2100mm, and coil weights ranging from 3 to 25 metric tons. It is important to note that these dimensions and weights can be customized to meet the requirements of different industries and applications.

- Q: How does stainless steel soap work? I have read the detailed explanation on Wikipedia, but their desciption seems skeptical on the actual chemical process that may take place from using such an item. Is there an actual scientific explanation to how stainless steel soap is able to clean your hands, when it is only a piece of metal?

- Metal Soap Bar

- Q: How are steel coils inspected for impact resistance?

- Steel coils are typically inspected for impact resistance using various methods to ensure their durability and ability to withstand external forces. One common method is the drop test, where a steel coil is dropped from a specified height onto a hard surface. This test simulates the impact that the coil may encounter during transportation or handling. During the drop test, the coil is visually inspected for any visible signs of damage, such as dents, cracks, or deformations. Additionally, the coil may undergo further examinations, such as ultrasonic testing or magnetic particle inspection, to detect any hidden internal defects that could compromise its impact resistance. Another method used to inspect steel coils for impact resistance is the pendulum test. In this test, a pendulum with a known weight and height is swung and impacts the coil's surface. The energy absorbed by the coil during the impact is measured, and this data is used to evaluate its resistance to impact. Furthermore, steel coils may undergo laboratory tests, such as Charpy impact testing, to determine their resistance to sudden impacts. This test involves striking a notched sample of the coil with a pendulum hammer, measuring the amount of energy absorbed by the sample, and evaluating its impact strength. Overall, a combination of drop tests, visual inspections, non-destructive testing methods, pendulum tests, and laboratory tests are used to inspect steel coils for impact resistance. These inspections ensure that the coils meet the required standards and can withstand the potential challenges they may encounter during transportation, storage, and use.

- Q: What are the main factors that affect the strength of steel coils?

- The main factors that affect the strength of steel coils are the composition of the steel, the manufacturing process, and the heat treatment applied.

- Q: We have to do a project for school on steel mines and i need 4 PROPERTIES OF A STEEL MINE PLEASE HELP!!! URGENT!!!

- The existence of them would be a good start. Steel is produced from iron ore, not mined.

Send your message to us

Steel Sheets,Steel Plates,Steel Coils from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 250000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords