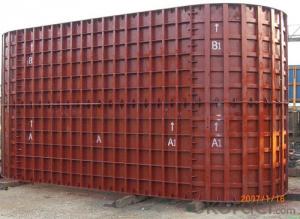

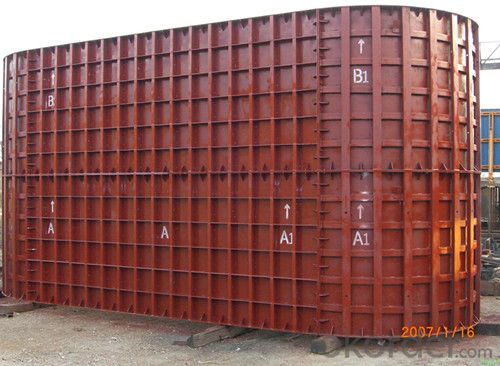

Steel Form for Common Building with Smooth Surface of Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q: How does steel formwork impact the overall project management?

- Steel formwork can have a significant impact on the overall project management in various ways. First and foremost, steel formwork is known for its durability and longevity, which means it can be reused multiple times throughout the project. This reduces the need for frequent replacements and repairs, saving both time and money. Moreover, steel formwork provides a high level of accuracy and precision, ensuring that the concrete structures are built according to the specified dimensions and specifications. This not only enhances the quality of the project but also minimizes the chances of rework or corrective measures, thereby saving time and resources. Additionally, steel formwork offers greater flexibility and versatility compared to traditional wooden formwork. It can be easily adjusted and modified to accommodate changes in design or unforeseen circumstances during the construction process. This adaptability enables project managers to make on-site adjustments quickly and efficiently, keeping the project on track and minimizing delays. Furthermore, steel formwork is known for its faster installation and dismantling process. This allows for faster construction cycles, enabling project managers to meet tight deadlines and complete the project within the scheduled timeframe. The faster turnaround time also improves project efficiency and reduces overall project costs. Lastly, steel formwork is considered a safer option compared to other formwork materials. It provides a stable and secure platform for workers, minimizing the risk of accidents and injuries. By prioritizing worker safety, project managers can maintain a productive and efficient work environment. In conclusion, steel formwork has a positive impact on overall project management by enhancing durability, accuracy, flexibility, speed, and safety. Utilizing steel formwork can lead to improved project outcomes, reduced costs, and enhanced efficiency, ultimately contributing to the successful completion of the project.

- Q: How does steel formwork impact the overall energy efficiency of a structure?

- Steel formwork can positively impact the overall energy efficiency of a structure in several ways. Firstly, steel formwork is highly durable and reusable, reducing the need for frequent replacements and minimizing material waste. This helps in conserving energy required for manufacturing new formwork. Secondly, steel formwork offers excellent thermal properties, reducing heat loss or gain through the structure, thereby enhancing its insulation and reducing the energy demand for heating or cooling. Lastly, the precision and accuracy of steel formwork facilitate the construction of airtight structures, minimizing air leakage and improving energy efficiency by reducing the energy required for climate control. Overall, steel formwork contributes to the energy efficiency of a structure through its durability, thermal performance, and superior construction quality.

- Q: How is steel formwork secured to the ground?

- To ensure stability and safety during the construction process, there are several methods available for securing steel formwork to the ground. Ground anchors are commonly used, typically made of steel or concrete. These anchors are driven into the ground at regular intervals along the formwork's perimeter. Steel rods or cables are then used to connect the anchors with the formwork, creating a strong and secure attachment to the ground. Alternatively, steel stakes can be employed when the ground is unsuitable for ground anchors, such as in rocky or uneven terrains. These stakes are driven into the ground at regular intervals, and the formwork is attached to them using various clamps or brackets. In addition to ground anchors and stakes, concrete footing or foundation can also be utilized to secure the steel formwork to the ground. This method involves pouring concrete footings or foundations at regular intervals along the formwork's perimeter. Bolts or other fasteners are then employed to attach the formwork to the concrete, ensuring a solid and stable connection. The specific method for securing steel formwork to the ground may vary depending on the construction project's requirements and the ground conditions. Following the manufacturer's instructions and consulting with structural engineers is crucial to ensure the proper installation and secure attachment of the formwork to the ground.

- Q: Can steel formwork be used for both residential and commercial projects?

- Steel formwork can serve both residential and commercial projects effectively. Renowned for its strength and capacity to bear heavy loads, steel formwork is a flexible and enduring choice extensively employed in construction. Its adaptability enables convenient customization to cater to diverse project demands, irrespective of whether they pertain to residential or commercial ventures. Among its merits are notable advantages like exceptional concrete finish, swift assembly, and extensive reusability. In both residential and commercial construction, steel formwork finds widespread application in foundations, walls, slabs, columns, and beams.

- Q: How does steel formwork contribute to the overall durability of the concrete structure?

- Steel formwork contributes to the overall durability of a concrete structure in several ways. Firstly, steel formwork provides a strong and rigid framework for pouring and shaping the concrete. This ensures that the concrete is properly supported during the curing process, preventing any deformation or collapse that could compromise the structure's integrity. Additionally, steel formwork is highly resistant to the corrosive effects of concrete, which contains alkaline substances that can slowly erode other materials over time. This resistance to corrosion ensures that the formwork remains stable and intact throughout the construction process, maintaining the shape and dimensions of the concrete elements. Moreover, steel formwork allows for precise and accurate construction, resulting in a concrete structure with consistent dimensions and smooth finishes. This precision minimizes the chances of structural weaknesses or flaws in the concrete, enhancing its overall durability. Furthermore, steel formwork is reusable, making it a cost-effective option for construction projects. By using steel formwork multiple times, the overall durability of the concrete structure is improved as the formwork retains its strength and stability over numerous applications. In conclusion, steel formwork plays a crucial role in enhancing the overall durability of a concrete structure. Its strength, resistance to corrosion, precision, and reusability ensure that the concrete is properly supported, accurately constructed, and able to withstand external forces, contributing to a long-lasting and robust structure.

- Q: What are the common types of steel used for formwork?

- The specific application and requirements determine the common types of steel used for formwork. However, in formwork construction, several types of steel are commonly utilized. 1. Mild Steel: This type of steel is frequently employed in formwork due to its affordability, accessibility, and ease of manipulation. With a low carbon content, mild steel is relatively pliable and can be easily bent or shaped. Nevertheless, it may not be suitable for heavy-duty or high-stress applications. 2. High Tensile Steel: Also known as high-strength steel, high tensile steel is a sturdier and more resilient alternative to mild steel. It contains alloys that enhance its tensile strength, making it perfect for heavy-duty formwork applications that involve higher loads or stresses. Although high tensile steel is more expensive than mild steel, it offers superior structural integrity. 3. Stainless Steel: In formwork applications where corrosion resistance is crucial, stainless steel is often employed. With a high chromium content, it forms a protective layer on the surface, preventing rust and corrosion. Stainless steel is commonly used in marine or coastal construction projects, as well as in areas with high humidity or chemical exposure. 4. Reinforcing Steel: Also known as rebar, reinforcing steel is frequently used in reinforced concrete formwork. It comprises steel bars or mesh embedded within the concrete to provide additional strength and stability. Reinforcing steel is typically made of carbon steel, but stainless steel rebar is also available for applications that require corrosion resistance. When selecting the appropriate type of steel for formwork, it is important to consider factors such as load requirements, environmental conditions, and budget constraints. Consulting with a structural engineer or construction professional can help ensure the right steel type is chosen for the specific project.

- Q: How is steel formwork assembled and disassembled?

- Steel formwork is typically assembled by connecting individual steel panels together using various types of locks or clamps. This allows for the creation of a sturdy and adjustable framework that can be tailored to the desired shape and size of the concrete structure. To disassemble, the locks or clamps are released, allowing the panels to be removed and repositioned for future use. This process is efficient, as steel formwork is reusable and can be easily dismantled, making it a cost-effective solution for construction projects.

- Q: Can steel formwork be used for industrial projects?

- Yes, steel formwork can be used for industrial projects. Steel formwork offers high strength, durability, and stability, making it suitable for demanding industrial applications. It can withstand heavy loads, provide accurate and precise formwork, and be reused multiple times, making it cost-effective for industrial projects.

- Q: How does steel formwork accommodate for different concrete pouring rates?

- Steel formwork is a construction material renowned for its versatility in accommodating various concrete pouring rates. Its adjustable nature allows for quick and efficient adjustments to match the required pouring rate. A key feature of steel formwork that enables it to adapt to different pouring rates is its modular and customizable design. By easily assembling and disassembling the formwork, construction teams can construct any desired shape or size. This flexibility empowers them to modify the formwork to suit different pouring rates. For instance, when a higher pouring rate is necessary, additional formwork panels can be added to increase capacity and facilitate faster concrete pouring. Furthermore, steel formwork is highly regarded for its robustness and strength. This ensures its ability to withstand the pressure exerted by the concrete during pouring, regardless of the pouring rate. The sturdiness of steel formwork prevents any deformation or collapse, guaranteeing the proper containment and shaping of the concrete according to the desired structure. Moreover, steel formwork's reusability is another notable advantage. It can be utilized for multiple construction projects, making it a cost-effective choice. The initial investment in steel formwork can be easily recovered over time. Consequently, construction teams can adapt the formwork to different pouring rates without incurring significant additional expenses. In conclusion, steel formwork is an extremely adaptable construction material that effortlessly accommodates varying concrete pouring rates. Its modular design, strength, and reusability make it the preferred choice for construction projects where pouring rates may fluctuate. With steel formwork, construction teams possess the flexibility to adjust the formwork to match the required pouring rate, ensuring a seamless and efficient concrete pouring process.

- Q: I would like to ask you 60 models of building steel formwork, steel mold fixed method and fixed plate type fixed hole number

- P6015:600 * 1500mm, P6012:600 * 1200mm, P6009:600 * 900mm, construction templates generally use U card or bolt fixation

Send your message to us

Steel Form for Common Building with Smooth Surface of Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords