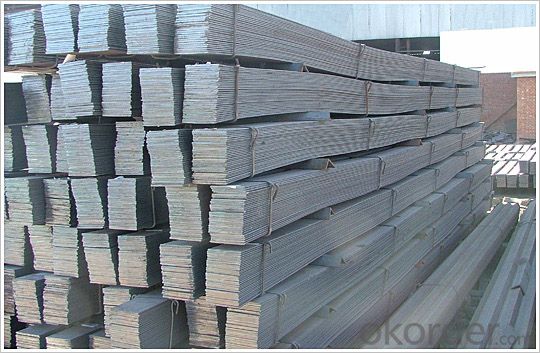

Steel Flat Bar Q235 Hot Rolled Black Mild Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Flat Bar Q235 Hot Rolled Black Mild Steel Flat Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Flat Bar Q235 Hot Rolled Black Mild Steel Flat Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar Q235 Hot Rolled Black Mild Steel Flat Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

| Name | carbon hot rolled black mild steel flat bar |

| Standard | AISI, ASTM, BS,DIN,GB,JIS |

| Grade | A36, SS400, Q235, Q345, S235,S275 |

| Dimensions | 1.5mm-14mm |

| Length | 6-12m |

| Technique | carbon hot rolled black mild steel flat bar |

| Tolerance | As the standard or as your requirement |

| Application | Metal structure, bridge, machiner, shipbuilding industry |

| Certificated | BV carbon hot rolled black mild steel flat bar |

| MOQ | 25 tons |

| Delivery | Within 25 days after deposit |

| Payment | T/T or L/C |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the load-bearing capacities of steel flat bars?

- The load-bearing capacities of steel flat bars vary depending on their dimensions and specific grades. Generally, steel flat bars have high strength and can support significant amounts of weight. However, it is essential to consult the manufacturer's specifications or engineering guidelines to determine the precise load-bearing capacity for a specific steel flat bar.

- Q: What are the different types of surface coatings available for steel flat bars?

- There are several types of surface coatings available for steel flat bars, each offering unique benefits and characteristics. 1. Galvanized Coating: This is a common type of coating where a layer of zinc is applied to the surface of the steel flat bar. It provides excellent corrosion resistance, protecting the steel from rust and other environmental factors. 2. Powder Coating: In this process, a dry powder is applied to the steel flat bar and then heated to form a durable coating. Powder coating offers a wide range of colors and finishes, making it a popular choice for decorative and protective purposes. 3. Epoxy Coating: Epoxy coatings are known for their excellent adhesion and chemical resistance. They provide a tough and durable layer that can withstand harsh environments, making them suitable for industrial applications. 4. Paint Coating: Paint coatings are a cost-effective option for protecting steel flat bars. They can be applied in various colors and finishes, providing both aesthetic appeal and protection against corrosion. 5. Anodized Coating: Anodizing is commonly used on aluminum, but it can also be applied to steel flat bars. This process involves creating an oxide layer on the surface, which enhances corrosion resistance and improves the appearance of the steel. 6. Chrome Plating: Chrome plating involves depositing a layer of chromium onto the steel flat bar surface. This coating provides excellent hardness, wear resistance, and a polished appearance. 7. Phosphate Coating: Phosphate coatings are often used as a pre-treatment before painting or powder coating. They enhance the adhesion of subsequent coatings and provide additional corrosion resistance. It is important to consider the specific requirements of your application when choosing the appropriate surface coating for steel flat bars. Factors such as corrosion resistance, durability, aesthetics, and cost should be taken into account to ensure the best choice for your needs.

- Q: What is the minimum yield strength of a steel flat bar?

- The grade of steel being used determines the minimum yield strength of a steel flat bar. Each grade of steel has its own specific minimum yield strength. Take, for instance, the commonly used grade A36, which boasts a minimum yield strength of 36,000 PSI. Nevertheless, there are stronger grades available, like A572, with a minimum yield strength of 50,000 PSI. To determine the suitable grade and minimum yield strength for a steel flat bar, it is crucial to refer to the specifications and requirements of the particular project or application.

- Q: Are steel flat bars suitable for fabrication of industrial machinery?

- Indeed, steel flat bars prove to be an appropriate choice for the construction of industrial machinery. Steel, a material known for its exceptional durability and strength, lends itself perfectly to the development of robust machinery capable of enduring the rigorous demands posed by industrial applications. The flat bar shape ensures structural stability and versatility, facilitating effortless fabrication and the opportunity to tailor the design to meet specific requirements. Moreover, steel flat bars boast remarkable resistance to corrosion, a vital characteristic in industrial settings where machinery may encounter moisture or chemicals. In summary, steel flat bars emerge as a dependable and economically viable option for the fabrication of industrial machinery.

- Q: Are steel flat bars suitable for making defense industry equipment or vehicles?

- Steel flat bars are indeed suitable for the production of defense industry equipment and vehicles. With its exceptional durability and strength, steel proves to be an optimal material for applications demanding resistance against impact, wear, and extreme conditions. The flat configuration of steel bars facilitates effortless fabrication and assembly into diverse components and structures, thereby rendering it versatile for defense industry equipment and vehicles. Moreover, steel is easily obtainable and cost-effective, guaranteeing efficient manufacturing and upkeep of defense equipment. Furthermore, steel can be readily tailored and adjusted to meet precise specifications, including ballistic protection or structural integrity, thereby further augmenting its appropriateness for defense industry applications.

- Q: Are steel flat bars suitable for making machinery frames or chassis?

- Yes, steel flat bars are commonly used in the construction of machinery frames or chassis due to their strength, durability, and ability to withstand heavy loads. They provide excellent structural support and can be easily welded or bolted together to create a sturdy and reliable frame or chassis for various types of machinery.

- Q: What is the difference between carbon steel and stainless steel flat bars?

- The main difference between carbon steel and stainless steel flat bars lies in their composition and properties. Carbon steel flat bars are primarily made of iron and carbon, with a maximum carbon content of 2.1%. This makes them strong and durable, but they are not resistant to corrosion. On the other hand, stainless steel flat bars contain a high percentage of chromium (at least 10.5%) along with iron and other elements. This chromium content forms a protective layer on the surface of the steel, making it highly resistant to corrosion and rust. Due to its corrosion resistance, stainless steel flat bars are commonly used in applications where exposure to moisture or chemicals is a concern, such as in marine environments or the food industry. Carbon steel flat bars, on the other hand, are often used in applications where strength and durability are the primary requirements, such as construction and manufacturing. Another notable difference is the appearance. Carbon steel flat bars have a dull gray finish, while stainless steel flat bars have a shiny, reflective surface. This aesthetic difference can be a factor in certain applications where appearance matters, such as architectural or decorative purposes. In summary, the key differences between carbon steel and stainless steel flat bars are their corrosion resistance, composition, and appearance. Carbon steel is strong and durable but prone to corrosion, while stainless steel is highly resistant to corrosion and offers a shiny finish. The choice between the two depends on the specific requirements of the application at hand.

- Q: What are the different bending techniques for steel flat bars?

- There are several bending techniques for steel flat bars, including cold bending, hot bending, and press braking. In cold bending, the bar is bent manually or using a machine without the need for heat. Hot bending involves heating the bar to a specific temperature and then shaping it using specialized tools or machines. Press braking is a technique that uses a hydraulic press to bend the bar to the desired angle.

- Q: Can steel flat bars be used in the manufacturing of agricultural machinery?

- Indeed, when it comes to the manufacturing of agricultural machinery, steel flat bars are a viable option. Their versatility and durability make them well-suited for a range of applications within the agricultural industry. Specifically, they can be utilized in the construction of frames, supports, brackets, and other essential structural components found in machinery like tractors, combines, tillers, and harvesters. The superior strength and rigidity of steel flat bars ensure that the machinery remains resilient and long-lasting, even in the harshest agricultural environments. Furthermore, their ability to be easily welded, bent, and shaped to meet specific design requirements renders them a preferred choice in the manufacturing of agricultural machinery.

- Q: What are the safety considerations when working with steel flat bars?

- When working with steel flat bars, important safety considerations include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential injuries from sharp edges or falling bars. It is crucial to ensure that the work area is well-ventilated and free from any flammable materials as sparks generated during cutting or welding processes can pose fire hazards. Additionally, proper handling techniques should be followed to avoid strains or injuries, and using appropriate tools and equipment, such as clamps or vices, can help stabilize the bars and minimize the risk of accidents.

Send your message to us

Steel Flat Bar Q235 Hot Rolled Black Mild Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords