Steel Flat Bar Prime Low Carbon Metal Iron Flat by Slitted

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Steel Flat Bar Prime Low Carbon Metal Iron Flat by Slitted at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Flat Bar Prime Low Carbon Metal Iron Flat by Slitted are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar Prime Low Carbon Metal Iron Flat by Slitted are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled sheet slitted

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q4: How many tons of steel products could be loaded in containers?

A4: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

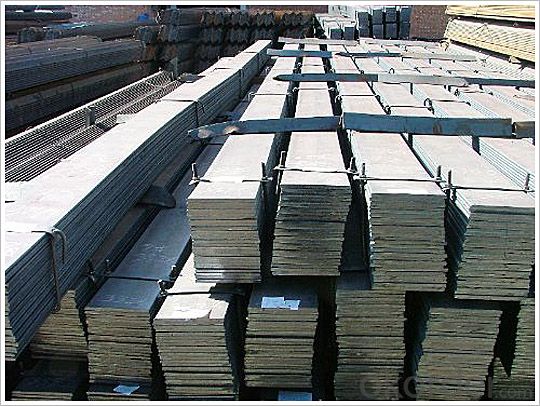

Images:

- Q: What are the standard lengths available for steel flat bars?

- The standard lengths available for steel flat bars typically range from 6 feet to 20 feet.

- Q: Can steel flat bars be used in the manufacturing industry?

- Steel flat bars are widely used in the manufacturing industry for their versatility, strength, and durability. They find extensive applications in the production of machinery, tools, construction materials, and automotive components. These bars serve as structural supports, frames, or reinforcements in manufacturing processes. Moreover, they can be easily welded, drilled, and shaped, making them suitable for various fabrication techniques. The exceptional mechanical properties and capacity to meet diverse application requirements make steel flat bars a favored option in the manufacturing industry.

- Q: How do you prevent bending or sagging of steel flat bars during installation?

- There are several measures that can be taken to prevent bending or sagging of steel flat bars during installation: 1. Handle the steel flat bars with care during transportation and installation to avoid deformations and bending. 2. Store the steel flat bars in a dry and flat area to prevent exposure to excessive moisture or uneven surfaces that can cause rusting and bending. 3. Ensure adequate support for the steel flat bars throughout the installation process by using appropriate clamps, jigs, or supports to hold them in place and distribute the load evenly. 4. Use the correct fastening techniques and materials, such as bolts, screws, or welding, to securely fasten the steel flat bars and resist bending or sagging. 5. Avoid exceeding the recommended load or weight capacity of the steel flat bars to prevent stress and deformation. Consult professionals if needed to determine the appropriate load limits for your specific application. 6. Regularly inspect the steel flat bars during and after installation to identify any signs of bending or sagging and promptly address any issues to prevent further damage. By following these preventive measures, you can minimize the risk of bending or sagging of steel flat bars during installation, ensuring their long-term structural integrity.

- Q: Can steel flat bars be used in the manufacturing of machinery?

- Yes, steel flat bars can be used in the manufacturing of machinery. Steel flat bars are commonly used in the construction of machinery components due to their strength, durability, and versatility. They can be shaped, cut, and welded to create various machine parts such as brackets, supports, frames, and structural elements. Additionally, steel flat bars offer good resistance to impact, wear, and corrosion, making them suitable for industrial applications in the manufacturing sector.

- Q: How long do steel flat bars typically last?

- Due to their durability and resistance to corrosion, steel flat bars are known to have a long lifespan. However, the length of time they last is contingent upon the conditions they are exposed to and the level of maintenance they receive. When properly cared for and shielded from moisture and harsh elements, steel flat bars can endure for many decades, or even longer. Conversely, if they are exposed to corrosive environments or neglected in terms of upkeep, their lifespan may be significantly diminished. Furthermore, the quality of the steel, the specific alloy used, and the amount of load or stress the flat bars experience can also impact their longevity. Therefore, it is crucial to conduct regular inspections and maintenance on steel flat bars to ensure they reach their optimal lifespan and performance.

- Q: How do steel flat bars compare to glass flat bars?

- Steel flat bars and glass flat bars have distinct characteristics and uses due to their different materials. Steel flat bars, made from a strong and durable metal alloy, find common applications in construction, manufacturing, and industry. They boast high tensile strength, excellent load-bearing capacity, and resistance to corrosion. Withstanding heavy loads, they are suitable for structural support, reinforcement, and framing. Moreover, steel flat bars are versatile, easily weldable, bendable, or fabricatable to meet specific project requirements. Different sizes, thicknesses, and finishes are available, providing flexibility in design and construction. On the contrary, glass flat bars consist of a brittle and transparent material, glass. They primarily serve architectural and decorative purposes, such as glass balustrades, partitions, shelving, or display fixtures. Glass flat bars offer a sleek and modern aesthetic, allowing light to pass through and creating an open and airy ambiance. Customization and design creativity are achievable through various colors, textures, and thicknesses. However, compared to steel, glass flat bars have limited load-bearing capacity, rendering them unsuitable for heavy structural or industrial applications. To summarize, steel flat bars are renowned for their strength, durability, and versatility, making them ideal for structural and industrial uses. On the other hand, glass flat bars provide a unique aesthetic appeal and are frequently employed in architectural and decorative applications. The choice between steel and glass flat bars depends on specific project requirements, encompassing load-bearing needs, design preferences, and intended applications.

- Q: Are steel flat bars suitable for marine environments?

- Marine environments can accommodate steel flat bars, contingent upon the specific steel type and the extent of exposure to saltwater or other corrosive elements. Stainless steel flat bars, specifically those crafted from marine-grade stainless steel like 316 or 316L, possess remarkable corrosion resistance and are frequently employed in marine applications. These stainless steel flat bars boast elevated levels of chromium and molybdenum, offering outstanding defense against saltwater, humidity, and other corrosive agents prevalent in marine environments. Nevertheless, not all steel flat bars prove suitable for marine environments. Ordinary carbon steel flat bars are susceptible to corrosion upon contact with saltwater and are prone to rapid deterioration. If carbon steel is utilized in marine applications, it necessitates proper safeguarding through coatings or galvanization to avert corrosion. To summarize, stainless steel flat bars, especially marine-grade stainless steel, prove ideal for marine environments owing to their exceptional resistance to corrosion. Conversely, ordinary carbon steel flat bars should be avoided unless adequately shielded to prevent corrosion.

- Q: Can steel flat bars be used in the oil and gas industry?

- Yes, steel flat bars can be used in the oil and gas industry. Steel flat bars are versatile and commonly used in various industries due to their strength and durability. In the oil and gas industry, steel flat bars are utilized for a wide range of applications such as supports, frames, platforms, and structural components. These bars are often made from carbon steel or alloy steel, which provide excellent resistance to corrosion, high temperatures, and pressure. Additionally, steel flat bars can be easily welded and fabricated to meet specific project requirements, making them a suitable choice for the oil and gas industry.

- Q: What is the difference between hot-rolled and extruded steel flat bars?

- Hot-rolled and extruded steel flat bars are both commonly used in various industries, but they differ in terms of their manufacturing processes and resulting properties. Hot-rolled steel flat bars are produced by heating a billet or slab of steel above its recrystallization temperature and then rolling it through a series of rollers to achieve the desired shape and dimensions. This process leads to the formation of a scaled surface, as the steel is exposed to high temperatures. Hot-rolled steel flat bars are known for their strength and toughness, making them suitable for applications that require load-bearing capabilities, such as construction and infrastructure projects. They also tend to have a rougher surface texture compared to extruded steel flat bars. On the other hand, extruded steel flat bars are created by forcing a heated billet of steel through a die to produce the desired shape. The extrusion process results in a smooth and uniform surface finish, as the steel is not subject to the same high temperatures as in hot rolling. Extruded steel flat bars are known for their precise dimensions and consistent cross-sectional shape, making them ideal for applications that require tight tolerances, such as manufacturing machinery and architectural components. They also tend to have a finer surface finish compared to hot-rolled steel flat bars. In summary, the main difference between hot-rolled and extruded steel flat bars lies in their manufacturing processes and resulting properties. Hot-rolled bars are known for their strength and toughness, with a rougher surface texture, while extruded bars offer precise dimensions and a smoother surface finish, suitable for applications that require tight tolerances.

- Q: How do steel flat bars contribute to the overall aesthetics of a design?

- Steel flat bars can contribute to the overall aesthetics of a design by adding a sleek and modern touch. Their clean lines and smooth surface create a visually appealing contrast when combined with other materials. Additionally, steel flat bars offer versatility in terms of shape and size, allowing designers to create unique and intricate patterns that enhance the overall visual appeal of the design.

Send your message to us

Steel Flat Bar Prime Low Carbon Metal Iron Flat by Slitted

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords