Melt Extract Stainless Steel Fiber - Copper Coated Steel Fiber from China NBM Company

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland)

Brand Name: cnbm

Model Number: GW-F

Material: Steel

Specifications

Such steel fiber using the technology into a row of single steel fiber bonding with water-soluble glue, to ensure that the steel fiber uniformly dispersed in concret, easily stirred, eliminate agglomerate phenomena such as, due to the bonding of steel fiberrows technology, steel fibers in concrete can be evenly distributed, so that the concrete structure by the impact of steel fibers can absorb impact energy, reduce stress concentration, effectively control the emergence and development of cracks in the concrete, to extend the structural life.

As reliable and efficient concrete reinforcement material, it is widely uesd in buildings, bridges, thin roof engineering, highway etc.

In bonding steel fiber concrete internal steel fiber, as long as ramming close-grained, and air separation, steel fiber generally don't happen corrosion phenomena. Dew in the concrete surface or in the crack width more than 0.25 mm, jumper cracks in the steel fiber, vulnerable to corrosion phenomena.

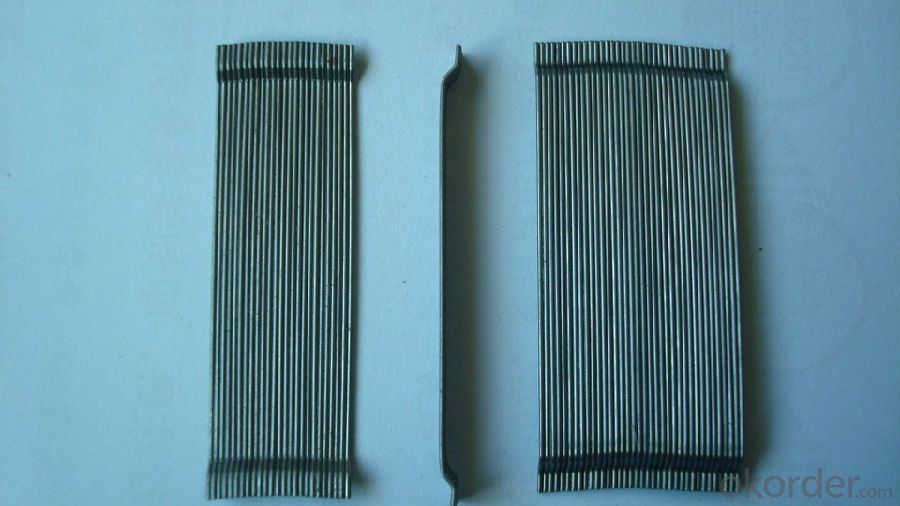

Picture

Steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: How does melt extract stainless steel fiber enhance the strength of concrete?

- Melt extract stainless steel fiber is an incredibly effective reinforcement material that enhances concrete strength in various ways. To begin with, the inclusion of stainless steel fibers improves the tensile strength of concrete, which plays a vital role in preventing cracks and fractures. These fibers create a reinforcement network within the concrete matrix, offering additional resistance against external forces and reducing the likelihood of structural failure. Furthermore, the unique characteristics of stainless steel, such as its high resistance to corrosion, allow the fibers to maintain their structural integrity over time. This ensures long-lasting durability and strengthens the overall concrete composition. Unlike other reinforcement materials, stainless steel fibers do not deteriorate or weaken when exposed to moisture, chemicals, or harsh environmental conditions. The addition of melt extract stainless steel fibers also enhances the impact resistance and ductility of concrete. These fibers can absorb and distribute energy upon impact, minimizing the risk of surface spalling or fragmentation. This is particularly advantageous in situations where the concrete faces heavy loads, dynamic forces, or extreme weather conditions. Moreover, the use of stainless steel fibers improves the fire resistance of concrete. Concrete reinforced with melt extract stainless steel fibers can withstand high temperatures and maintain its structural integrity for longer periods compared to traditional concrete. This is especially crucial in environments prone to fire or structures where fire protection is of utmost importance. Overall, melt extract stainless steel fibers greatly enhance concrete strength by improving tensile strength, impact resistance, ductility, and fire resistance. The inclusion of these fibers offers a reliable and efficient reinforcement solution, ensuring the longevity and structural integrity of the concrete.

- Q: What is the effect of melt extract stainless steel fiber on the crack width in concrete?

- The use of melt extract stainless steel fibers in concrete has a significant effect on the crack width. These fibers are added to the concrete mixture to enhance its durability and strength. When the concrete is subjected to external forces or temperature fluctuations, cracks may occur. However, the presence of stainless steel fibers helps to control and minimize the width of these cracks. The main reason behind this effect is the unique properties of stainless steel fibers. These fibers are known for their high tensile strength and ductility. When cracks start to form in the concrete, the stainless steel fibers act as reinforcement and distribute the stress across the matrix. This redistribution of stress helps to prevent the cracks from widening. Additionally, the presence of stainless steel fibers also improves the overall toughness of the concrete. As a result, the concrete becomes more resistant to crack propagation. This means that even if cracks do form, they are less likely to extend and cause significant damage. Moreover, melt extract stainless steel fibers also improve the overall durability of the concrete. They act as a barrier against corrosion, protecting the concrete from the harmful effects of moisture, chemicals, and other environmental factors. This enhances the lifespan of the concrete structure and reduces the need for frequent repairs or replacements. In summary, the use of melt extract stainless steel fibers in concrete has a positive effect on the crack width. These fibers reinforce the concrete matrix, distribute stress, and prevent cracks from widening. Furthermore, they improve the overall toughness and durability of the concrete, making it more resistant to crack propagation and extending its lifespan.

- Q: Can melt extract stainless steel fiber reduce the risk of spalling in high-strength concrete?

- Yes, melt extract stainless steel fiber can reduce the risk of spalling in high-strength concrete. Stainless steel fibers improve the tensile strength, ductility, and overall durability of concrete. When added to high-strength concrete, these fibers help to control cracking and minimize the potential for spalling, especially under severe loading conditions or in high-temperature environments.

- Q: How does melt extract stainless steel fiber affect the bond strength of shotcrete to substrate?

- The bond strength of shotcrete to the substrate can be greatly enhanced by utilizing melt extract stainless steel fiber. When incorporated into the shotcrete mix, these fibers aid in the even distribution of applied stresses, leading to enhanced cohesion between the shotcrete and the substrate. Within the shotcrete, the stainless steel fibers function as reinforcement, offering additional tensile strength and reducing the occurrence of cracking or delamination. This reinforcement plays a vital role in establishing a stronger bond between the shotcrete and the substrate, ultimately increasing the overall bond strength. Moreover, the exceptional properties of melt extract stainless steel fibers, including their high aspect ratio, mechanical strength, and resistance to corrosion, contribute to the improved bond strength. These fibers effectively interlock with both the shotcrete matrix and the substrate, establishing a robust and long-lasting connection. By enhancing the bond strength, melt extract stainless steel fiber also elevates the overall performance and durability of shotcrete applications. It enables better distribution of loads, heightened resistance against cracking, and improved resilience against environmental factors such as freeze-thaw cycles or chemical exposure. To summarize, the addition of melt extract stainless steel fiber significantly enhances the bond strength between shotcrete and the substrate. This improvement stems from the fiber's ability to distribute stresses, provide reinforcement, and interlock with both the shotcrete matrix and the substrate. Consequently, shotcrete applications incorporating melt extract stainless steel fiber exhibit superior performance, durability, and resistance against various external forces.

- Q: Is melt extract stainless steel fiber suitable for use in marine environments?

- Yes, melt extract stainless steel fiber is suitable for use in marine environments. Stainless steel is known for its corrosion resistance properties, making it highly resistant to the effects of saltwater and other corrosive elements found in marine environments. Melt extract stainless steel fiber is specifically designed to have increased strength and durability, making it an ideal choice for applications where it will be exposed to the harsh conditions of the marine environment. Additionally, the fiber's high melting point and ability to withstand extreme temperatures make it well-suited for marine applications where it may be exposed to high heat. Overall, melt extract stainless steel fiber is a reliable and effective choice for use in marine environments.

- Q: Is melt extract stainless steel fiber suitable for use in tunnel lining construction?

- Yes, melt extract stainless steel fiber is suitable for use in tunnel lining construction. It provides enhanced strength, durability, and resistance to corrosion, making it an ideal choice for reinforcing concrete in tunnels.

- Q: What are the different shapes and sizes of melt extract stainless steel fiber available?

- Melt extract stainless steel fibers are available in a variety of shapes and sizes to suit different applications and requirements. Some common shapes include straight fibers, crimped fibers, wavy fibers, and hooked fibers. In terms of sizes, melt extract stainless steel fibers can range from extremely fine, with diameters as small as 3 microns, to larger sizes such as 30 microns or more. The length of the fibers can also vary, typically ranging from a few millimeters to several centimeters. The choice of shape and size of melt extract stainless steel fibers depends on the specific application and the desired properties. For example, straight fibers are often used in applications where high tensile strength and stability are important, while crimped or wavy fibers provide better bonding with the matrix material in composites. Hooked fibers, on the other hand, offer improved anchoring and reinforcement in concrete applications. Overall, the availability of different shapes and sizes of melt extract stainless steel fibers allows for customization and optimization of their performance in various industries such as construction, automotive, aerospace, and textiles.

- Q: How does melt extract stainless steel fiber affect the thermal conductivity of concrete?

- The thermal conductivity of concrete can be significantly affected by the addition of melt extract stainless steel fibers. These fibers increase the material's thermal conductivity, allowing heat to be conducted more efficiently. This is mainly because stainless steel has a much higher thermal conductivity than concrete. When melt extract stainless steel fibers are added to concrete, they create conductive pathways for heat to travel through the material. This results in an overall increase in the thermal conductivity of the concrete, improving heat transfer and distribution. The enhanced thermal conductivity of concrete with stainless steel fibers has various benefits in concrete applications. For example, in structures where thermal management is crucial, such as high-rise buildings or infrastructure exposed to extreme temperatures, the addition of stainless steel fibers can help regulate and dissipate heat more effectively. This can prevent excessive heat build-up, reducing the risk of thermal expansion and potential structural damage. Moreover, the improved thermal conductivity of concrete with stainless steel fibers can enhance the efficiency of heating or cooling systems in buildings. By facilitating better heat transfer, the concrete acts as a more effective thermal mass, absorbing and releasing heat more efficiently. This reduces energy consumption and enhances comfort levels. However, it is important to note that the impact of melt extract stainless steel fibers on thermal conductivity may vary depending on factors like fiber content, fiber length, and fiber distribution within the concrete mix. Proper design and testing are necessary to ensure the desired thermal performance is achieved.

- Q: Can melt extract stainless steel fiber be used in wastewater treatment plant construction?

- Yes, melt extract stainless steel fiber can be used in wastewater treatment plant construction. It is often utilized to reinforce concrete in various structures within the plant, such as tanks, pipelines, and basins. The stainless steel fiber enhances the durability and strength of the concrete, making it resistant to corrosion and other chemical attacks commonly found in wastewater environments.

- Q: How does melt extract stainless steel fiber improve the impact resistance of concrete pipes?

- Melt extract stainless steel fiber improves the impact resistance of concrete pipes by reinforcing the material and providing additional strength. The fibers act as a reinforcement agent within the concrete matrix, effectively distributing and dissipating the energy from impact forces. This helps to prevent cracks and fractures, enhancing the overall durability and resistance of the concrete pipes to impacts.

Send your message to us

Melt Extract Stainless Steel Fiber - Copper Coated Steel Fiber from China NBM Company

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords